Method for preparing environment-friendly white fine renewable rubber

A technology of recycled rubber and production methods, applied in recycling technology, plastic recycling, etc., can solve the problems of coarse white recycled rubber particles, product application restrictions, environmental pollution, etc., to achieve smooth and delicate appearance, wide application range, wear-resistant. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

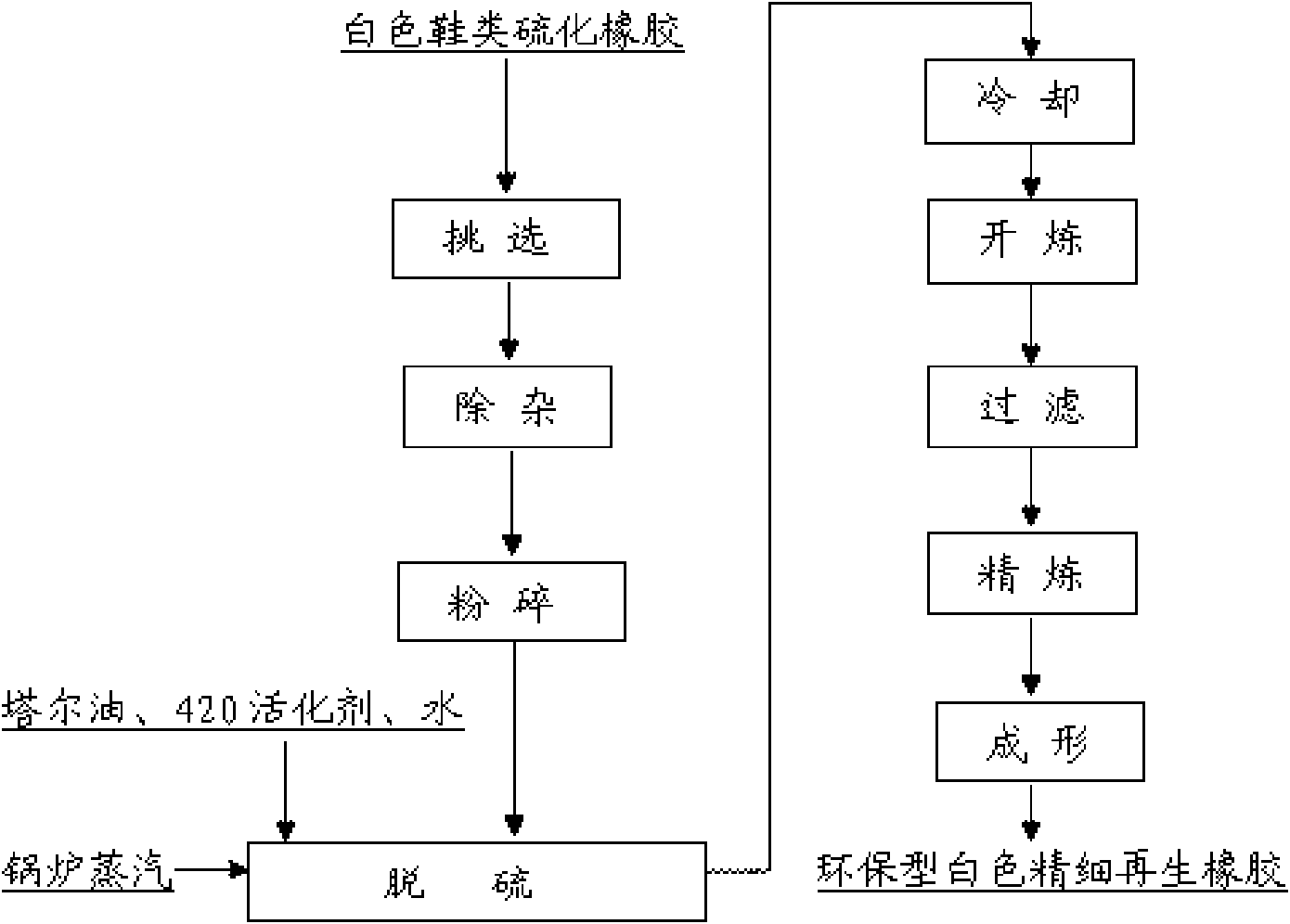

Method used

Image

Examples

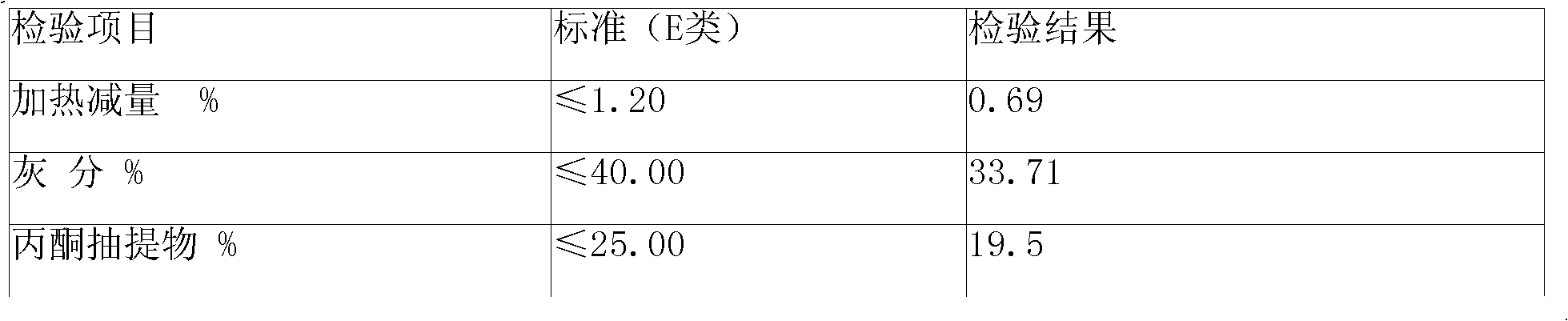

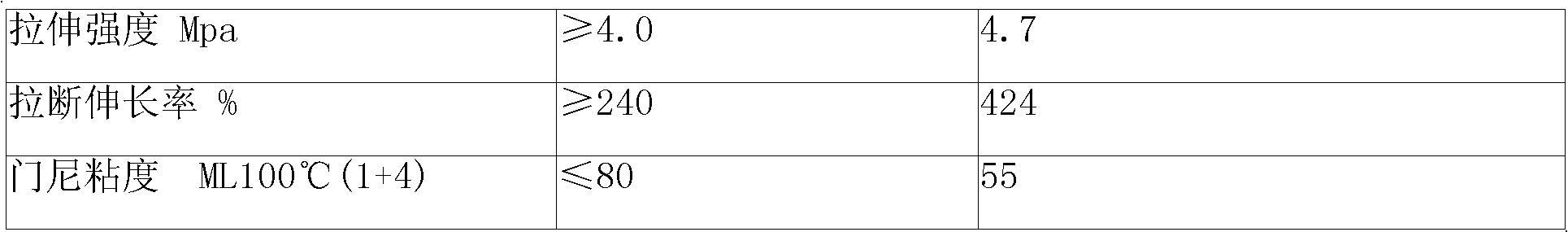

Embodiment 1

[0019] A production method of environmentally friendly white fine regenerated rubber: use waste white soles and white scraps as raw materials, select and cut them, remove metals, impurities and other rubber types, and obtain white clean rubber; use a pulverizer to grind the white clean rubber Grinding and pulverizing into white rubber powder with a particle size of 0.18-0.425 mm, the temperature of the roller of the pulverizer is controlled at 80-100 °C, and the roller distance is set at 0.25 mm; 120 parts by weight of white rubber powder, 5 parts of tall oil Parts, 0.6 parts of 420 activator, and 18 parts of water are put into the microcomputer automatic control desulfurization tank, and the mixer is turned on for stirring; steam is introduced, and the steam pressure in the tank rises from the initial 1.0Mpa to 2.0-2.2Mpa, and the temperature is 200-220 Keep warm for 120 minutes under the condition of ℃; then reduce the pressure in the tank to 0Mpa, open the valve to unload, a...

Embodiment 2

[0023] A production method of environmentally friendly white fine regenerated rubber: use waste white soles and leftover white as raw materials, select and cut them, remove metals, impurities and other rubber types, and obtain white clean rubber; use a pulverizer to grind the white clean rubber Grinding and pulverizing into white rubber powder with a particle size of 0.18-0.425mm, the temperature of the roller of the pulverizer is controlled at 80-100°C, and the roller distance is set at 0.3mm; 100 parts by weight of white rubber powder, 5.6 parts of tall oil 0.5 parts, 0.5 parts of 420 activators, and 21 parts of water are put into the microcomputer automatic control desulfurization tank, and the mixer is turned on for stirring; steam is introduced, and the steam pressure in the tank rises from the initial 1.0Mpa to 1.5-2.0Mpa, and at a temperature of 190-210 Keep warm for 130 minutes under the condition of ℃; then reduce the pressure in the tank to 0Mpa, open the valve to dis...

Embodiment 3

[0028] A production method of environmentally friendly white fine regenerated rubber: use waste white soles and leftover white as raw materials, select and cut them, remove metals, impurities and other rubber types, and obtain white clean rubber; use a pulverizer to grind the white clean rubber Grinding and pulverizing into white rubber powder with a particle size of 0.18-0.425mm, the temperature of the roller of the pulverizer is controlled at 80-100°C, and the roller distance is set at 0.2mm; 140 parts by weight of white rubber powder, 4 parts of tall oil Parts, 0.7 parts of 420 activator, and 15 parts of water are put into the computer automatic control desulfurization tank, and the mixer is turned on for stirring; steam is introduced, and the steam pressure in the tank rises from the initial 1.0Mpa to 1.8-2.2Mpa, and the temperature is 210-230 Keep warm for 110 minutes under the condition of ℃; then reduce the pressure in the tank to 0Mpa, open the valve to discharge the ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com