Method for preparing environment-friendly fine butyl renewable rubber

A technology of regenerated rubber and fine butyl, which is applied in recycling technology, plastic recycling, etc., can solve the problems of product application limitations, long desulfurization time, high production cost, etc., and achieve low desulfurization steam pressure, short desulfurization time, and air tightness Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

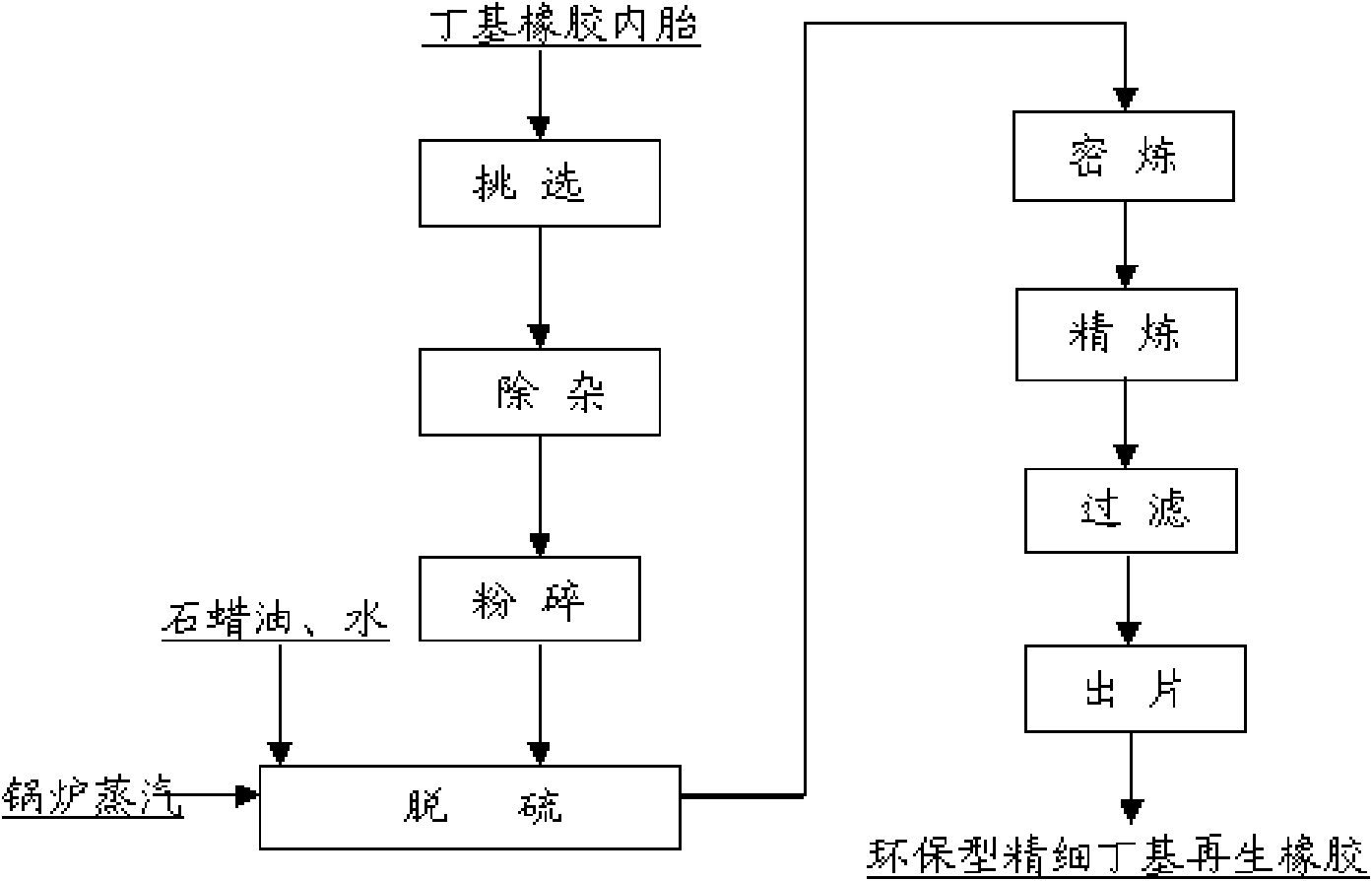

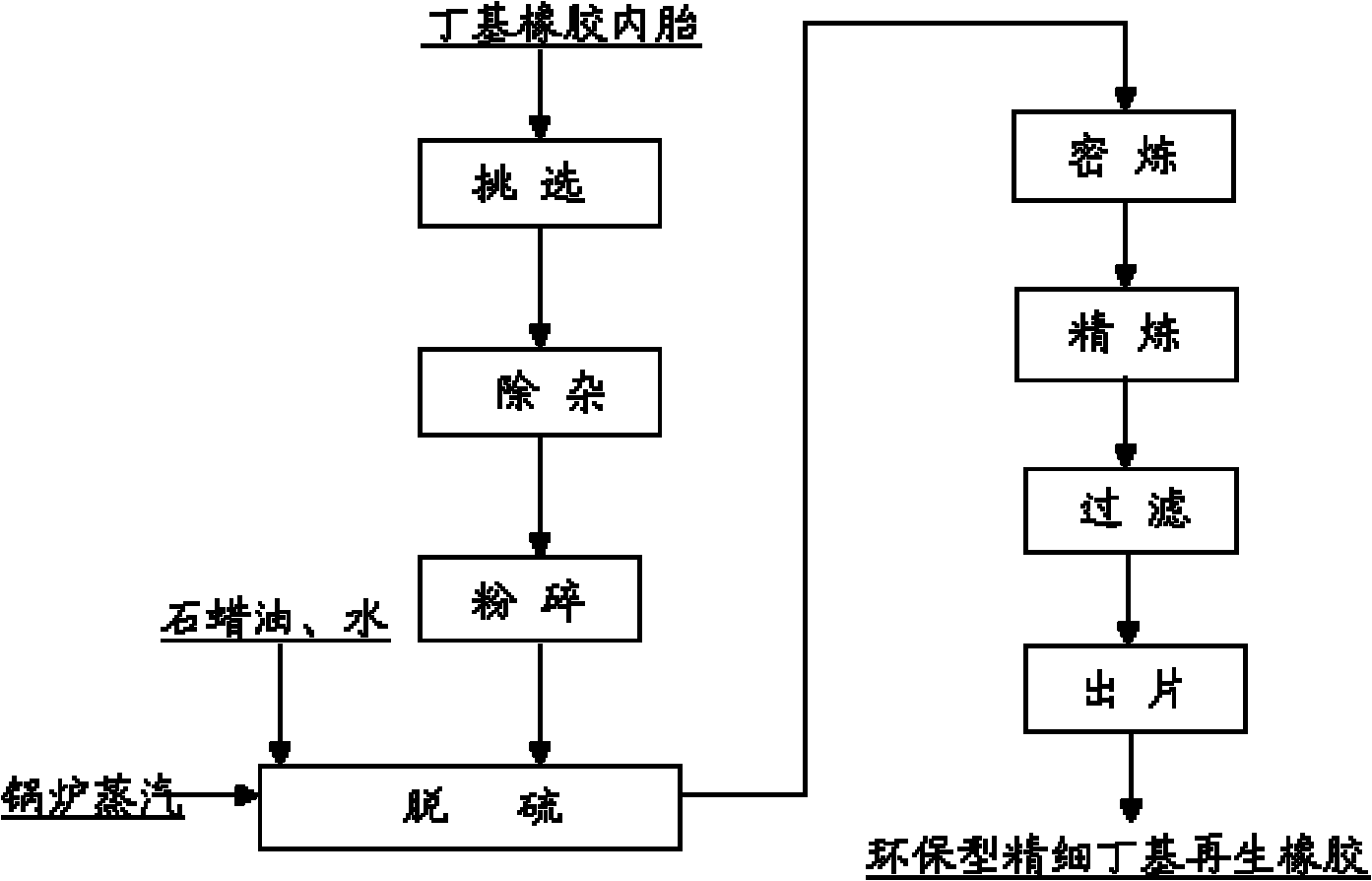

Method used

Image

Examples

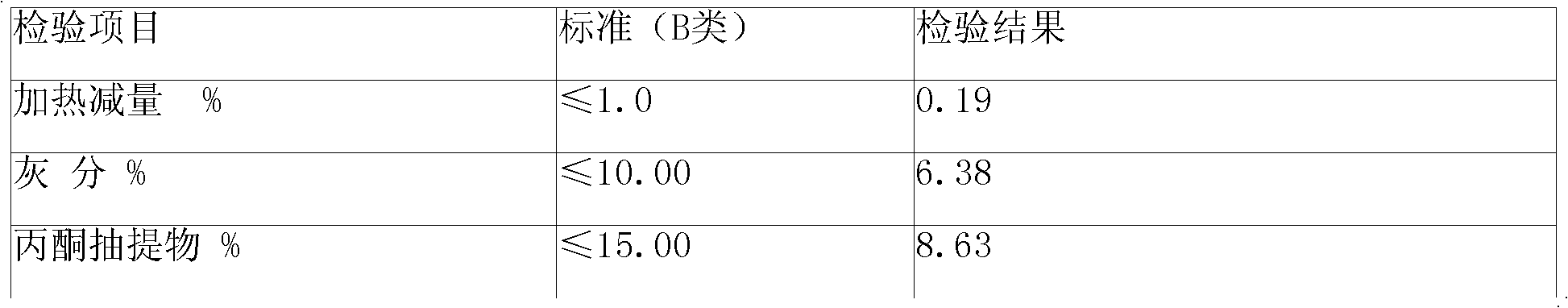

Embodiment 1

[0019] A production method of environmentally friendly fine butyl regenerated rubber: use waste butyl rubber inner tubes as raw materials, select them, cut off impurities such as patches and copper nozzles, clean and drain, and then grind and pulverize them with a pulverizer into a particle size of 0.18-0.425mm rubber powder, the temperature of the pulverizer roller is controlled at 80-90°C, and the roller distance is set at 0.25mm; 120 parts by weight of waste butyl rubber inner tube rubber powder, 2.5 parts of paraffin oil, 12 parts of water Put the parts into the microcomputer regeneration desulfurization tank, turn on the mixer to stir the materials in the tank; feed steam, the steam pressure in the tank rises from the initial 0.6Mpa to 1.3-1.5Mpa, and the desulfurization operation is completed after 80 minutes; after the time is up, the desulfurization tank The internal pressure drops to 0Mpa, unloading and rapid cooling; the cooled rubber material is banburyed with a 750 ...

Embodiment 2

[0024] A production method of environmentally friendly fine butyl regenerated rubber: use waste butyl rubber inner tubes as raw materials, select them, cut off impurities such as patches and copper nozzles, clean and drain, and then grind and pulverize them with a pulverizer into a particle size of For 0.18-0.425mm rubber powder, the temperature of the pulverizer roller is controlled at 90-100°C, and the roller distance is set at 0.2mm; 100 parts by weight of waste butyl rubber inner tube rubber powder, 4 parts of paraffin oil, and 10 parts of water Put the parts into the microcomputer regeneration desulfurization tank, turn on the mixer to stir the materials in the tank; feed steam, the steam pressure in the tank rises from the initial 0.6Mpa to 1.5-1.7Mpa, and the desulfurization operation is completed in 75 minutes; after the time is up, the desulfurization tank The internal pressure drops to 0Mpa, unloading and rapid cooling; the cooled rubber material is banburyed with a 7...

Embodiment 3

[0029] A production method of environmentally friendly fine butyl regenerated rubber: use waste butyl rubber inner tubes as raw materials, select them, cut off impurities such as patches and copper nozzles, clean and drain, and then grind and pulverize them with a pulverizer into a particle size of For 0.18-0.425mm rubber powder, the temperature of the pulverizer roller is controlled at 85-95°C, and the roller distance is set at 0.3mm; 140 parts by weight of waste butyl rubber inner tube rubber powder, 1 part of paraffin oil, and 14 parts of water Put the parts into the microcomputer regeneration desulfurization tank, turn on the mixer to stir the materials in the tank; feed steam, the steam pressure in the tank rises from the initial 0.6Mpa to 1.4-1.6Mpa, and the desulfurization operation is completed after 85 minutes; after the time is up, the desulfurization tank The internal pressure drops to 0Mpa, unloading and rapid cooling; the cooled rubber material is banburyed with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com