Engine throttle

A throttle and engine technology, applied in engine control, machine/engine, mechanical equipment, etc., can solve problems such as poor contact, mechanical wear, fuel waste, etc., to save motor costs, install firm and compact, and increase the range of options. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

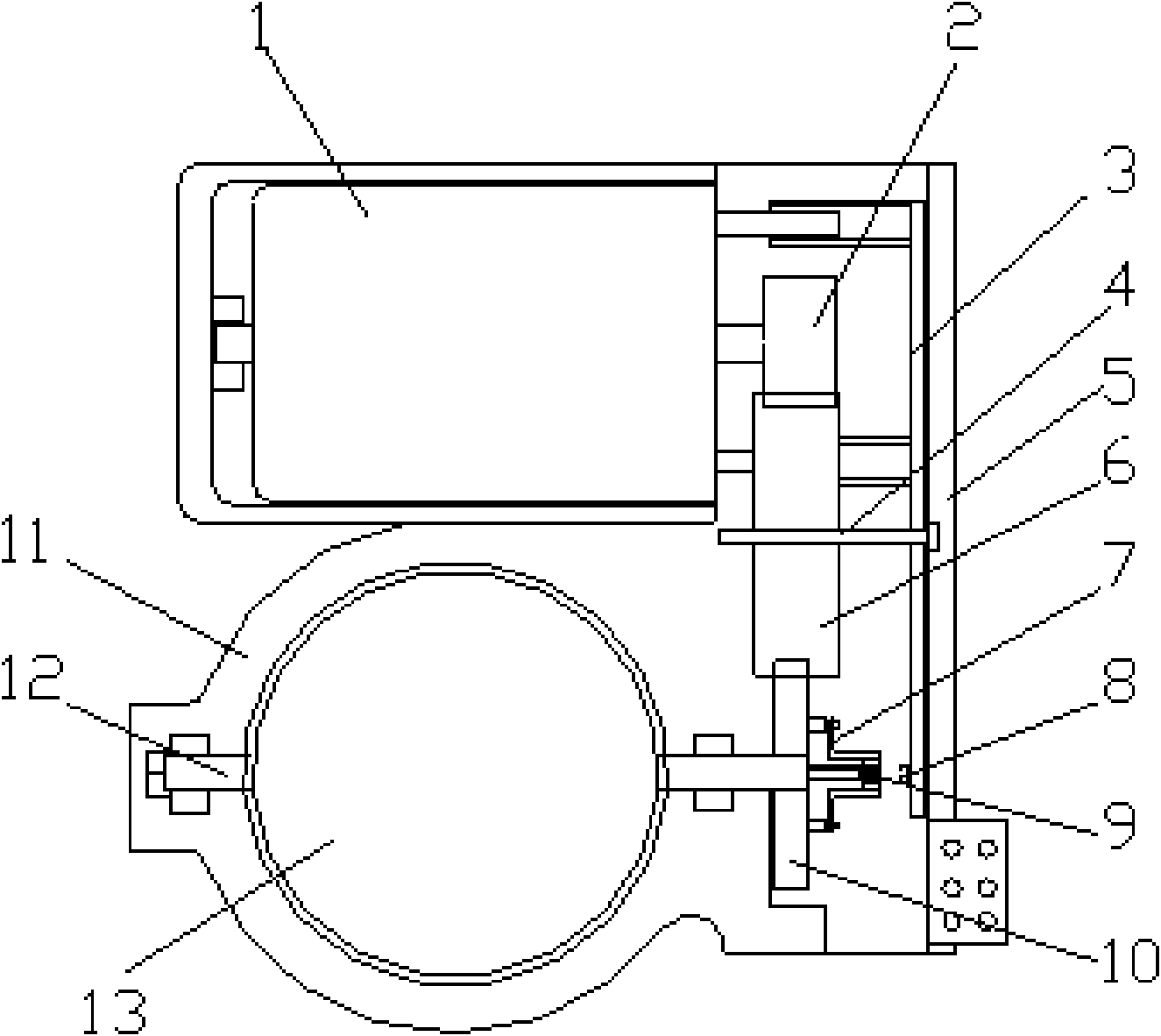

[0017] Accompanying drawing is a schematic structural view of the present invention, as shown in the figure: the non-contact electronic engine throttle of the present embodiment includes a throttle valve, a drive motor 1 and a control unit, and the throttle valve includes a valve body 11 and a valve plate 13. The valve plate 11 is installed on the valve body 13 through the valve plate shaft 12, and the control unit controls the drive motor 1 to drive the valve plate 11 through the valve plate shaft 12, and the valve plate shaft 12 is fixed and matched in the circumferential direction On the magnet steel 9, a Hall device 8 for collecting the rotation angle of the valve disc shaft 12 is fixedly arranged on the throttle valve relative to the magnet steel 9 in the axial direction, and the signal output end of the Hall device 8 is connected to the control unit.

[0018] In this embodiment, the drive motor 1 drives the valve plate shaft 12 through a gear transmission mechanism. The g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com