Control method of opening of large flow throttle valve for water

A control method and throttle valve technology, applied in the direction of feedback control, controllers with specific characteristics, electric controllers, etc., can solve the problems of valve stem displacement drift, compressor needs to be improved, and control accuracy is not high, etc. To achieve the effect of uniform flow change and good micro-adjustment performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

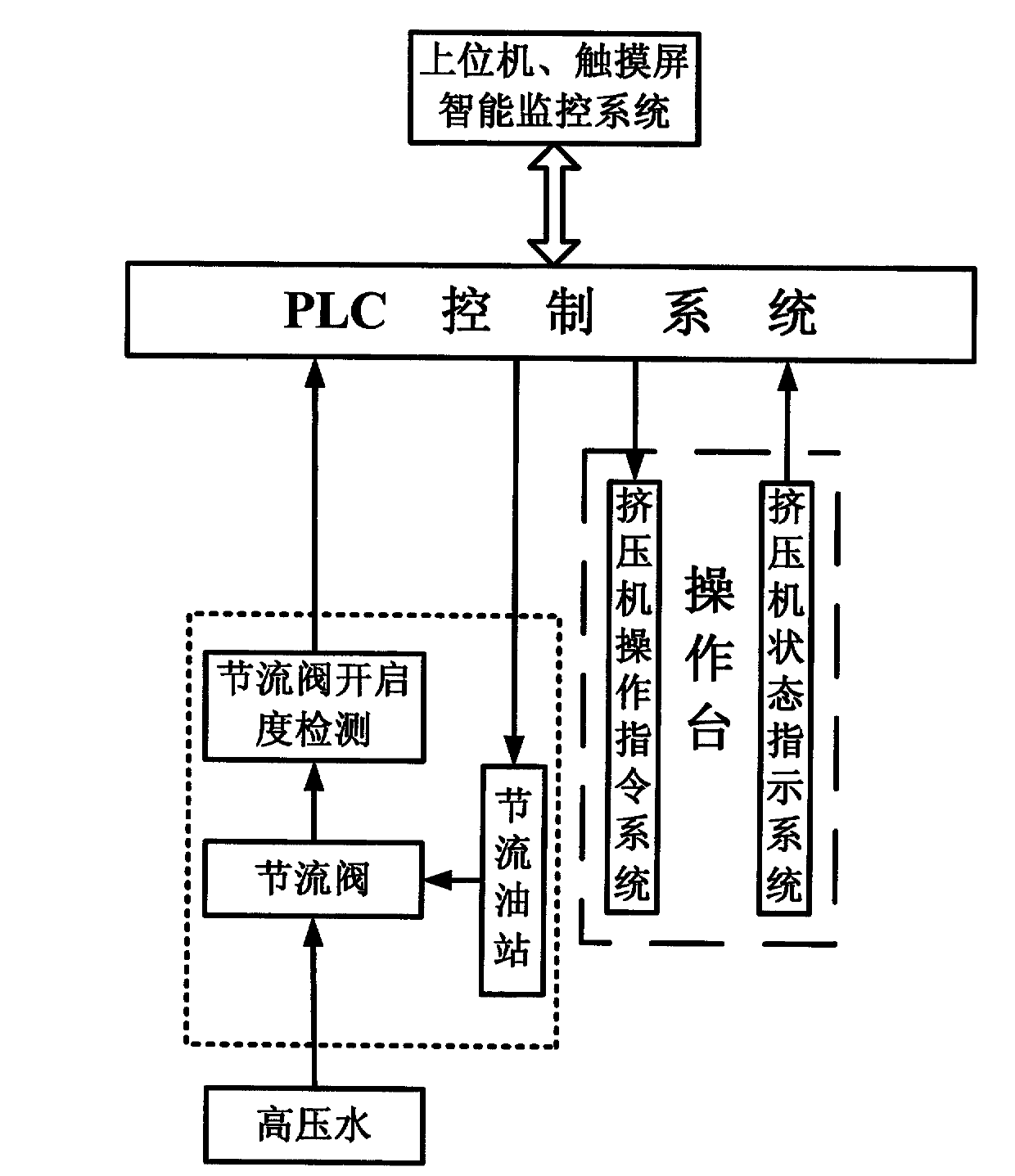

[0044] figure 2 The structure of the control system of the large-flow water throttle valve of the present invention is described, which includes the large-flow water throttle valve and its hydraulic drive system, state signal detection system, PLC control system, and upper computer (touch screen) real-time monitoring system.

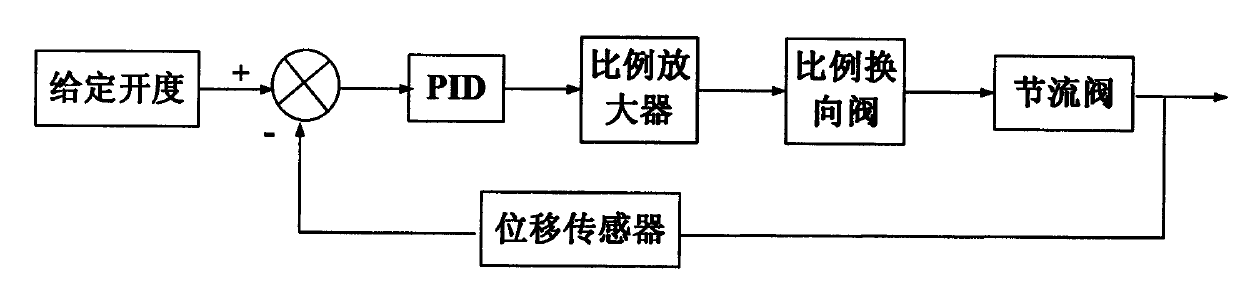

[0045] The operator can accurately set the opening degree of the throttle valve in the form of digital quantities on the monitoring system of the host computer (touch screen), and can continuously adjust it through the analog bar graph according to the actual situation. The displacement sensor detects the actual opening degree of the throttle valve (digital input) for real-time monitoring. After comparing the set opening degree with the actual opening degree through the PLC program, a signal difference is obtained, and the signal difference is input into the PID function block, and passed through the proportional amplifier. The flow and direction of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com