Cultivation water filtration method and device thereof

A filtration method and a technology of a filtration device, which are applied in the direction of filtration separation, separation method, chemical instrument and method, etc., can solve the problems of reducing the number of filtration times, reducing filtration efficiency, blocking the mesh of the filter screen, etc., so as to reduce the number of times of backwashing , increase the filtration time, and improve the filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

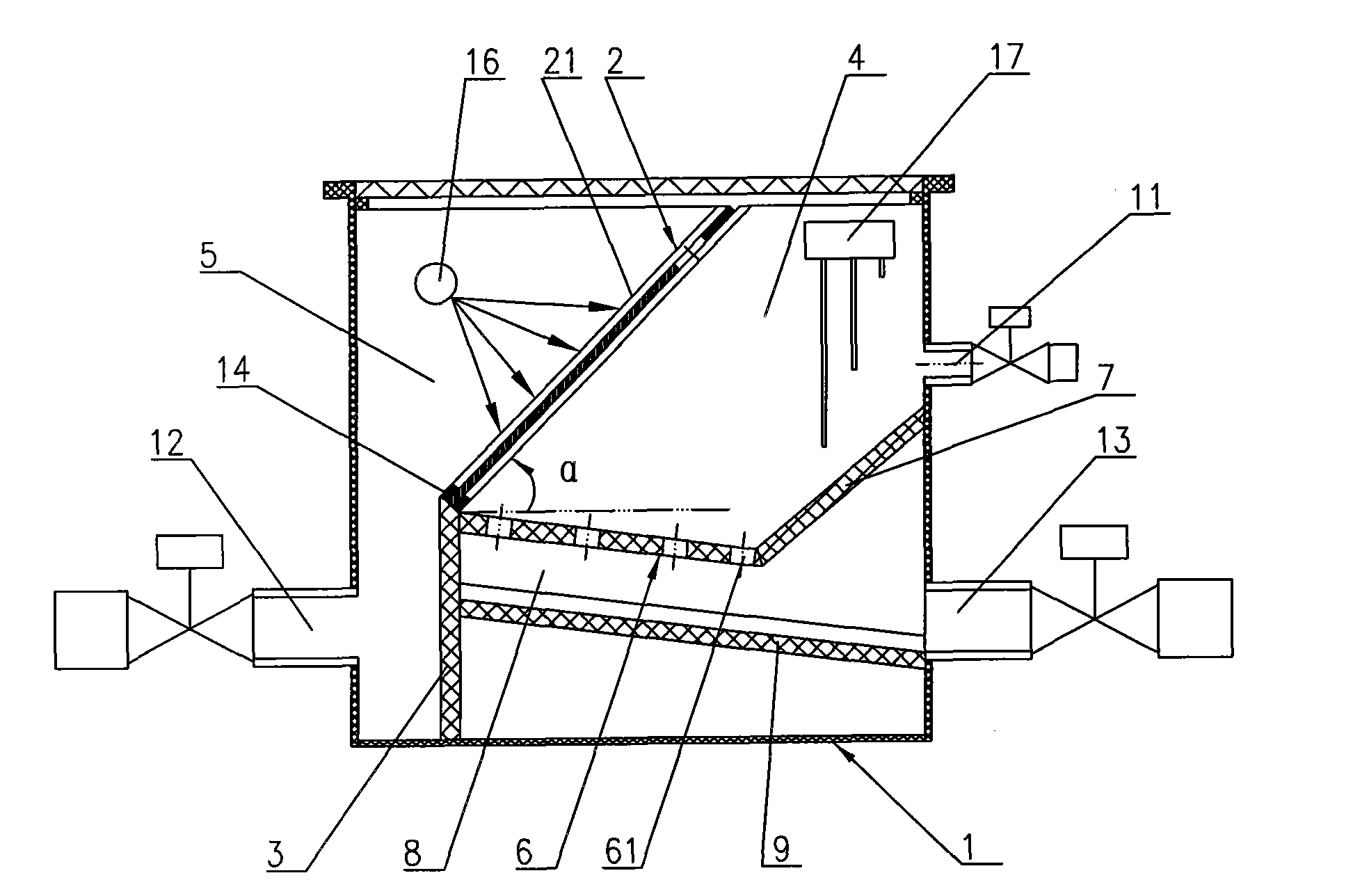

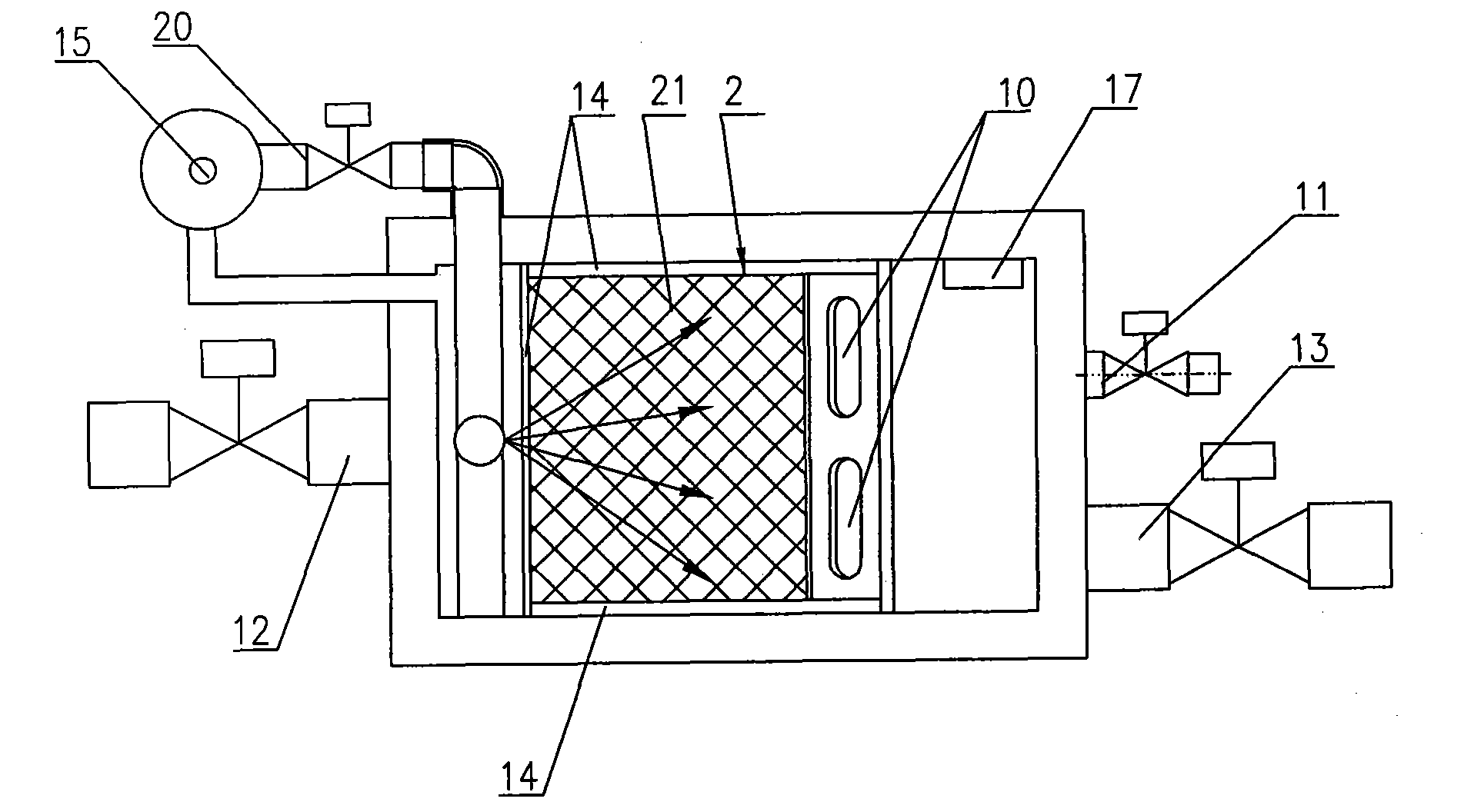

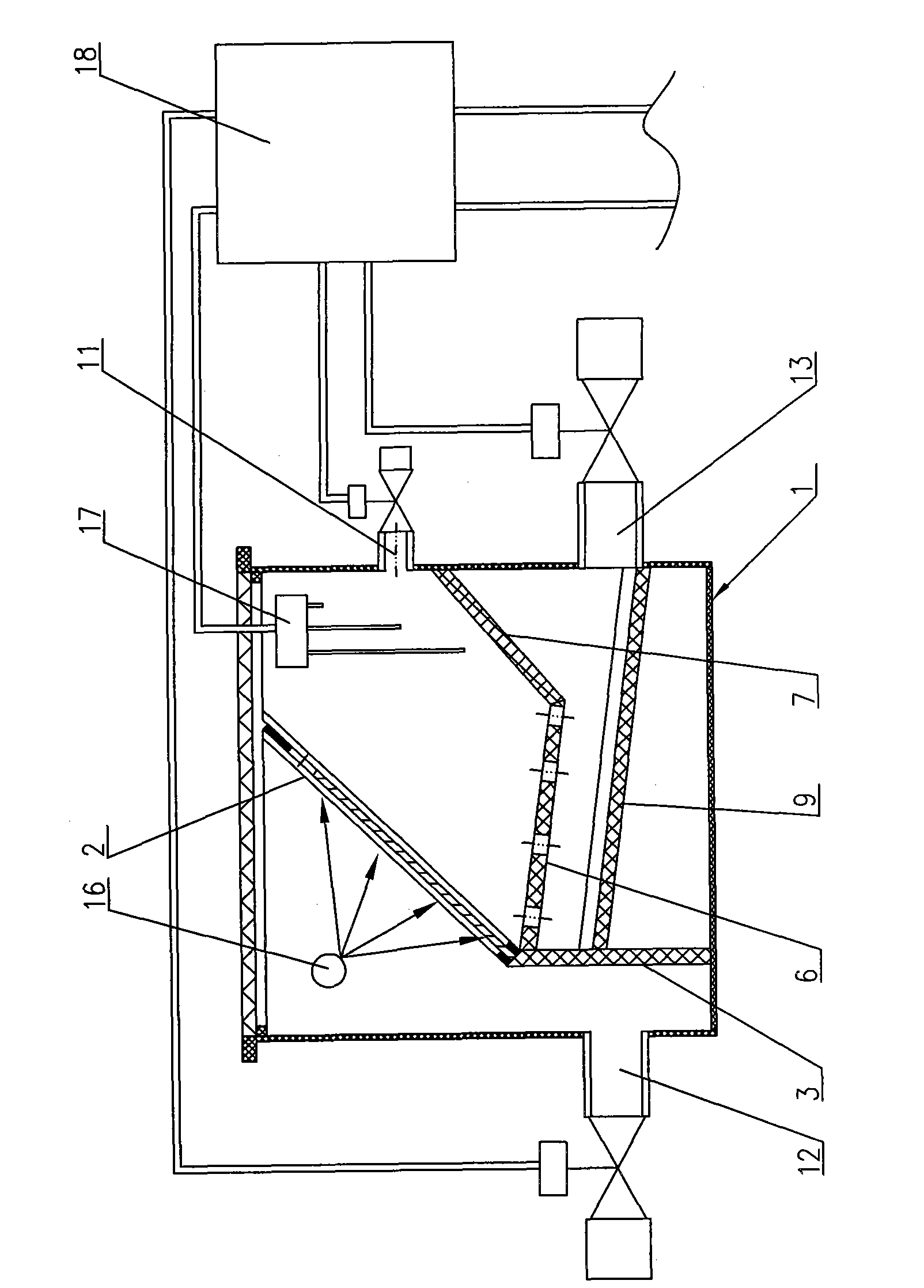

[0037] A method for filtering aquaculture water according to the present invention comprises a step of filtering aquaculture water, a sewage discharge step and a backwashing step, wherein:

[0038] The aquaculture water filtration step is: the water inlet 11 of the aquaculture water to be filtered is higher than the water outlet 12 of the filtered clear water, and the height difference that exists provides the potential energy for the aquaculture water to flow, and this potential energy is used as the driving force for the entire filtration process of the aquaculture water. A power source, which drives the aquaculture water to be filtered to pass through the filter screen 2 in a state of surging water flow from the bottom of the filter screen 2 upwards.

[0039] The sewage discharge step includes: after the aquaculture water is filtered, the dirt trapped by the filter screen 2 is naturally deposited downward and passes through the grille 6 that is arranged under the filter scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com