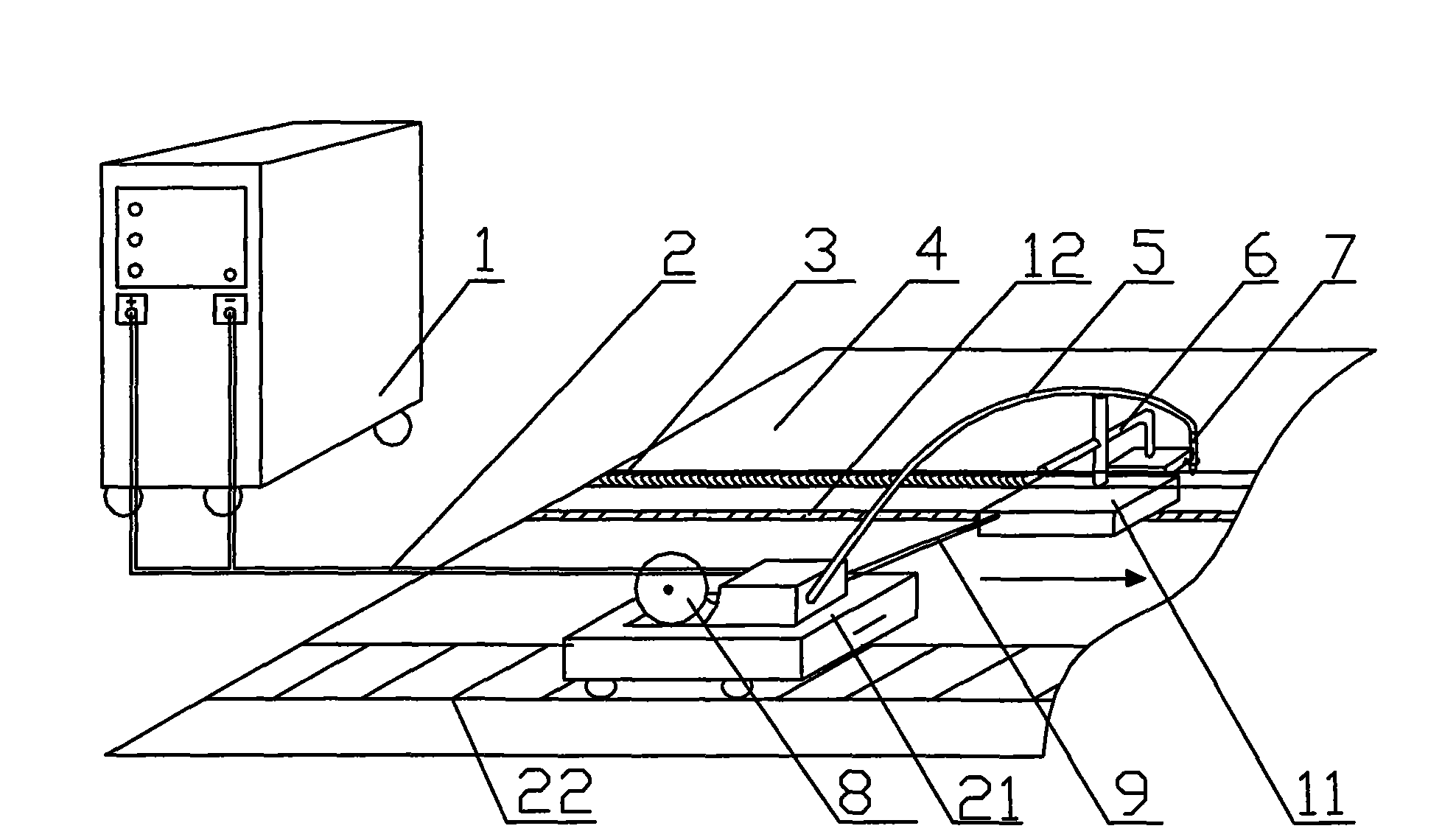

Double-type aluminum alloy walking arrangement for automatic MIG welding and welding method thereof

A walking equipment and aluminum alloy technology, which is applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve the problems such as the quality of easily deformed weld seams of aluminum alloy space curved thick plates, the high price of automatic welding machines, and the difficulty of guaranteeing them. , to achieve the effect of simple assembly and disassembly, comprehensive functions and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

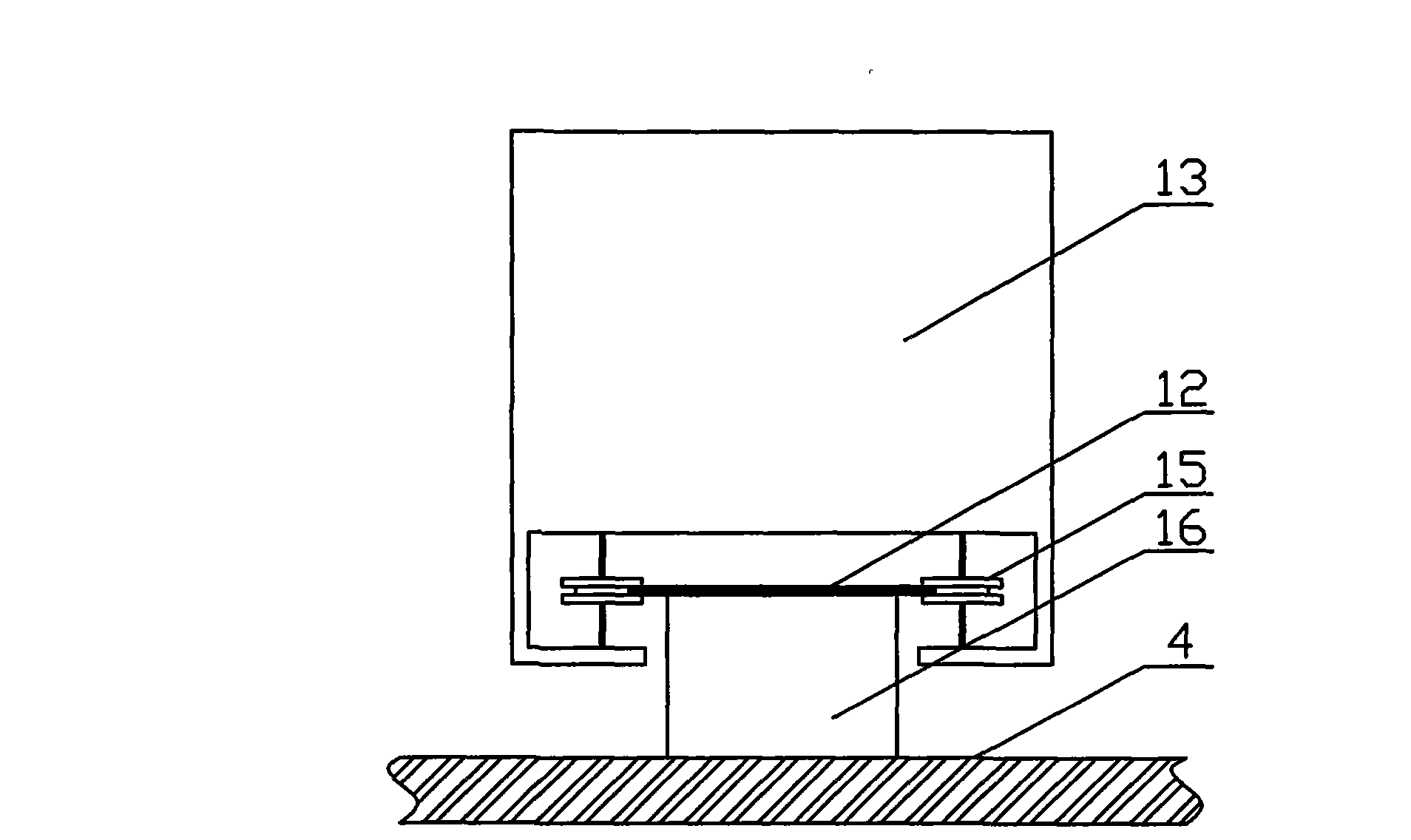

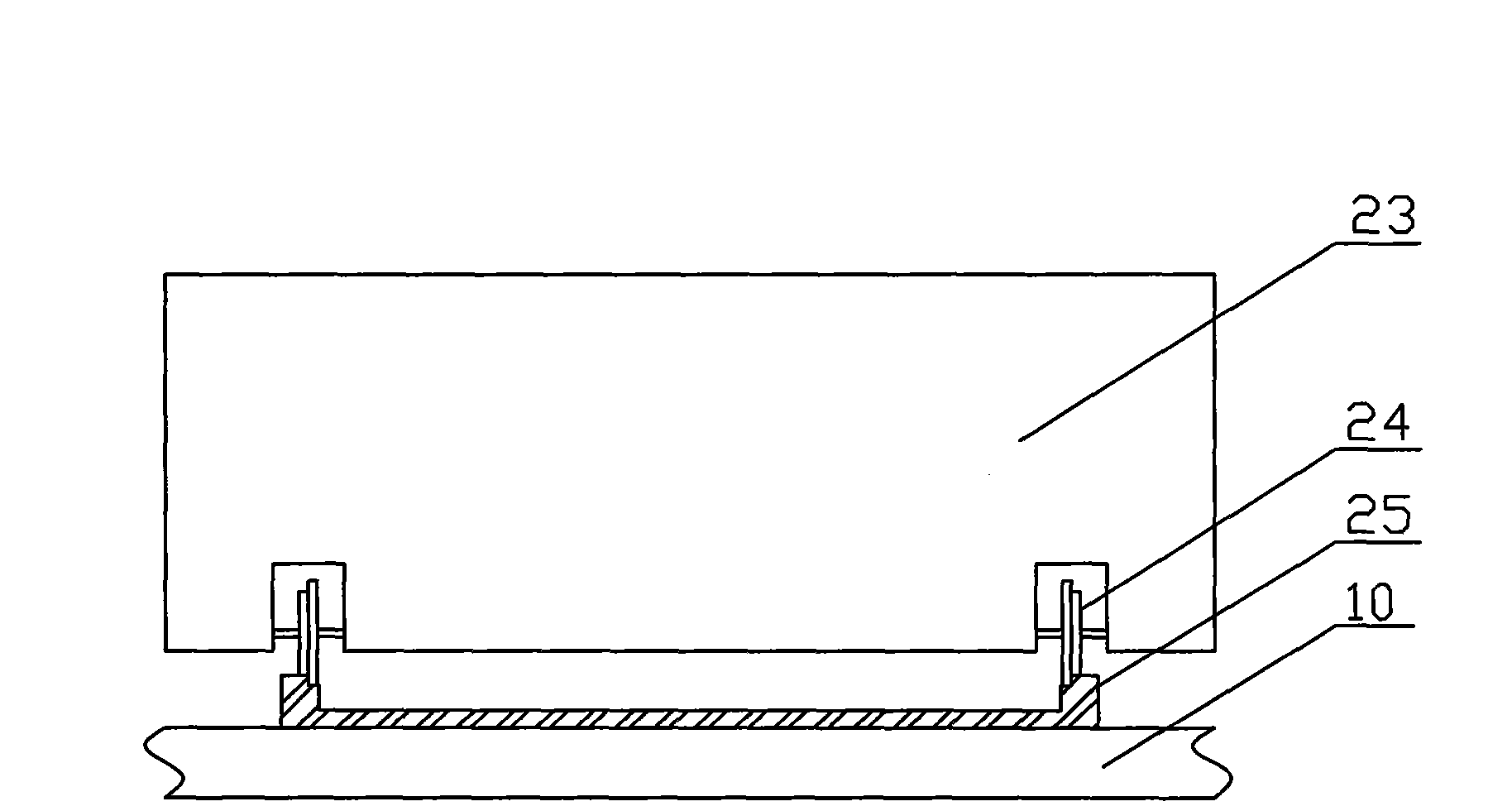

Method used

Image

Examples

Embodiment 1

[0043] Use the welding method of aluminum alloy automatic MIG welding double-body walking equipment to weld the 5083 aluminum alloy flat plate with a plate thickness of 20mm and a specification of 20×800×5000mm. The welding process adopts full automatic welding, and the welding wire is ER5183 aluminum welding wire with a diameter of Φ1. .6mm.

[0044] The blunt edge thickness h of the groove is 6 mm, the assembly gap p ranges from 0 to 2 mm, and the groove angle α is 60 degrees. For joint groove form, see Figure 6 shown.

[0045] The track setting adopts a flexible track that can be attached to the board surface and is flat welded.

[0046] Such as Figure 7 As shown, the upper surface in the figure is the front side, and the lower surface is the reverse side.

[0047] The specific welding technical parameters are shown in Table 1:

[0048] Table 120mm thick aluminum alloy plate automatic MIG welding process parameter record table

[0049]

[0050]

[0051] The we...

Embodiment 2

[0053] Use the welding method of aluminum alloy automatic MIG welding double-body walking equipment to weld the 5083 aluminum alloy arc-shaped plate with a plate thickness of 40mm and a specification of 40×1300×9000mm. Φ2.4mm.

[0054] The blunt edge thickness h of the groove is 6mm, the assembly gap p ranges from 0 to 3mm, and the groove angles α and β are 80° and 100° respectively. For joints and grooves, see Figure 4 shown.

[0055] The track setting adopts a flexible track that can be attached to the board surface and is flat welded.

[0056] Such as Figure 5 As shown in the figure, the upper surface is convex and the lower surface is concave.

[0057] Select the convex surface for welding, and the welding torch moves forward along the weld seam without swinging.

[0058] Select the concave surface for welding, and the welding torch swings forward perpendicular to the direction of the welding seam.

[0059] The specific welding technical parameters are shown in Tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Plate thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com