Novel energy-saving non-circular and non-cylindrical series ore heating furnace

A submerged arc furnace, energy-saving technology, used in furnaces, electric furnace heating, furnace components, etc., can solve the problems of long-term stable operation and high unit consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

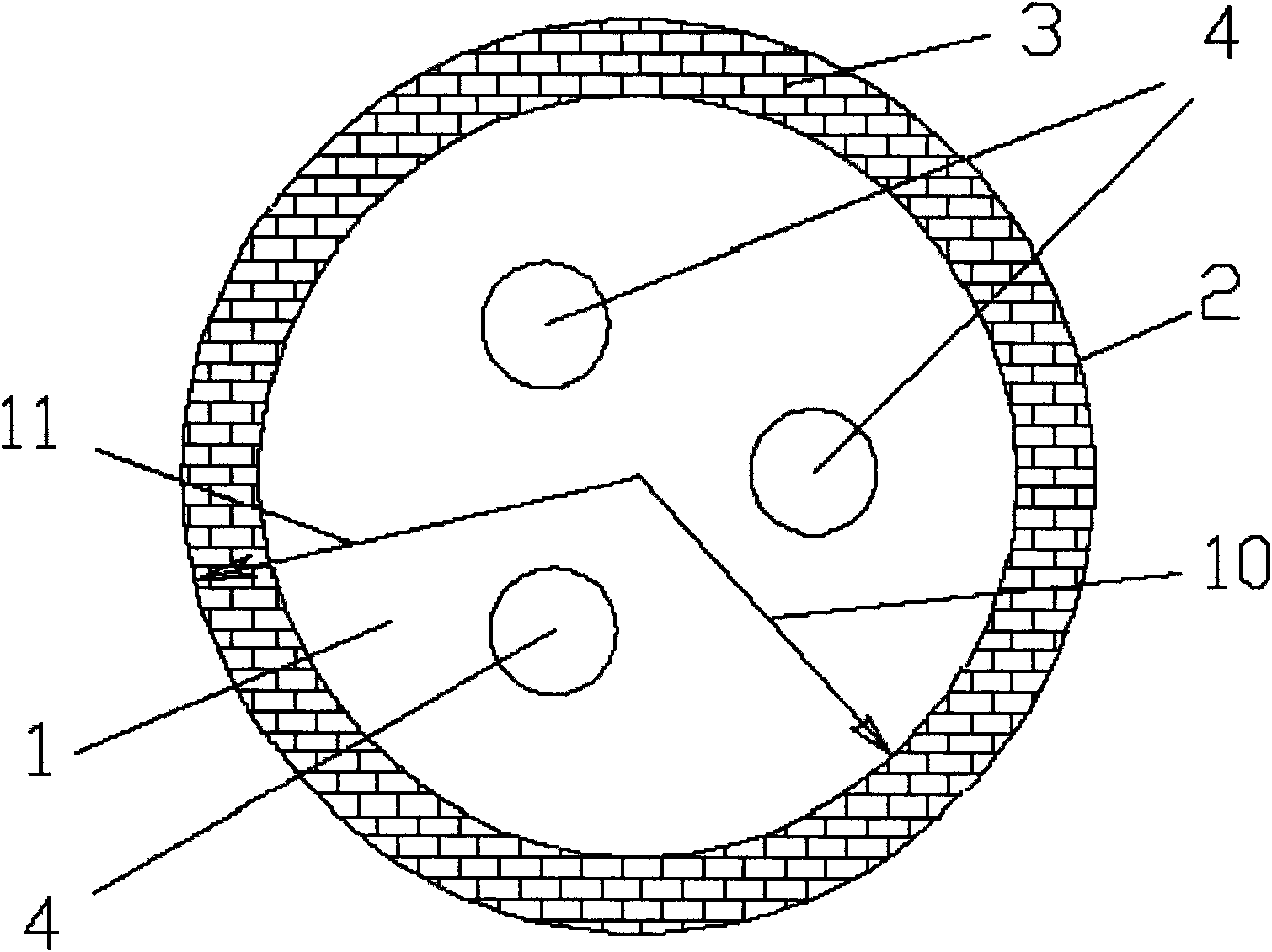

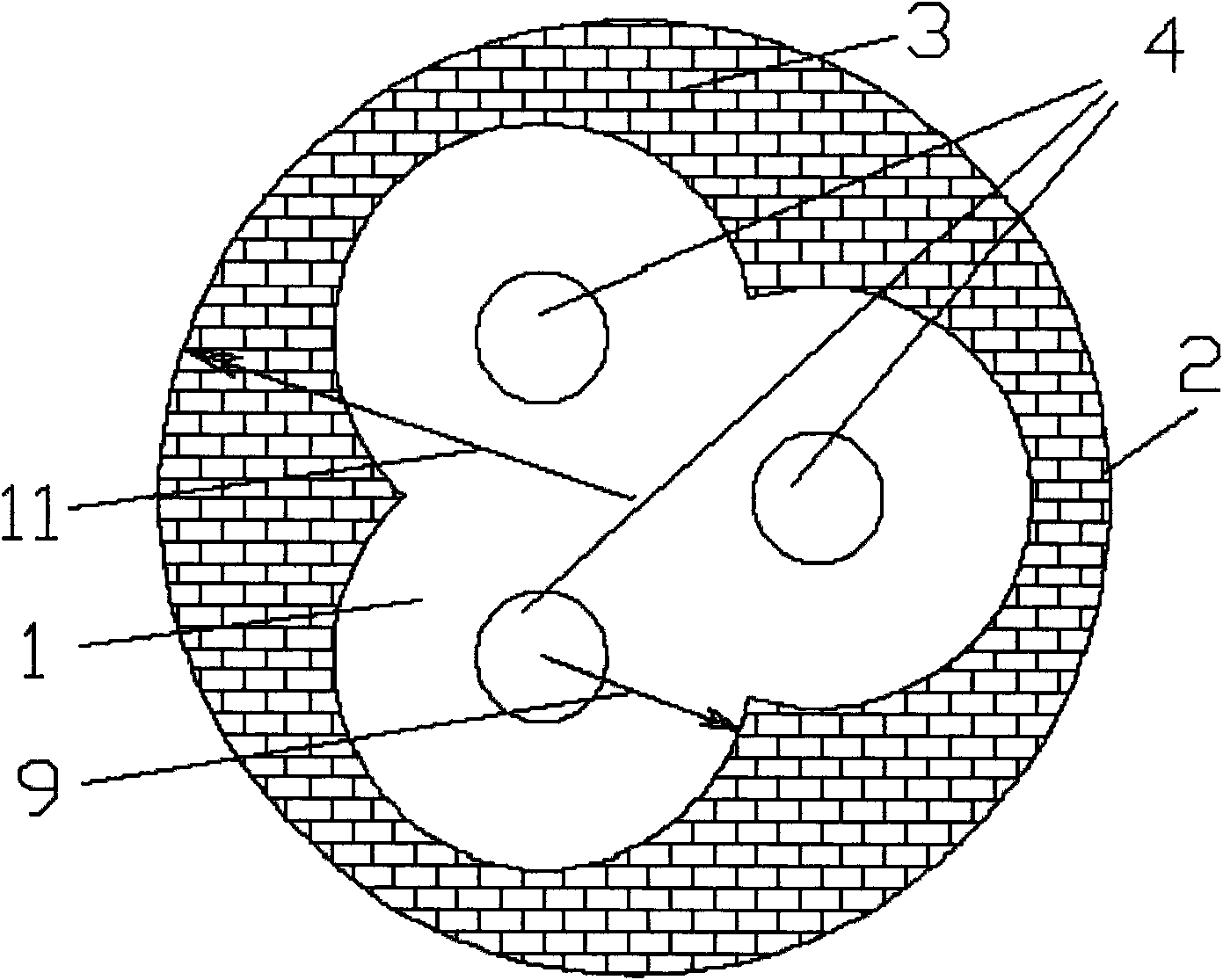

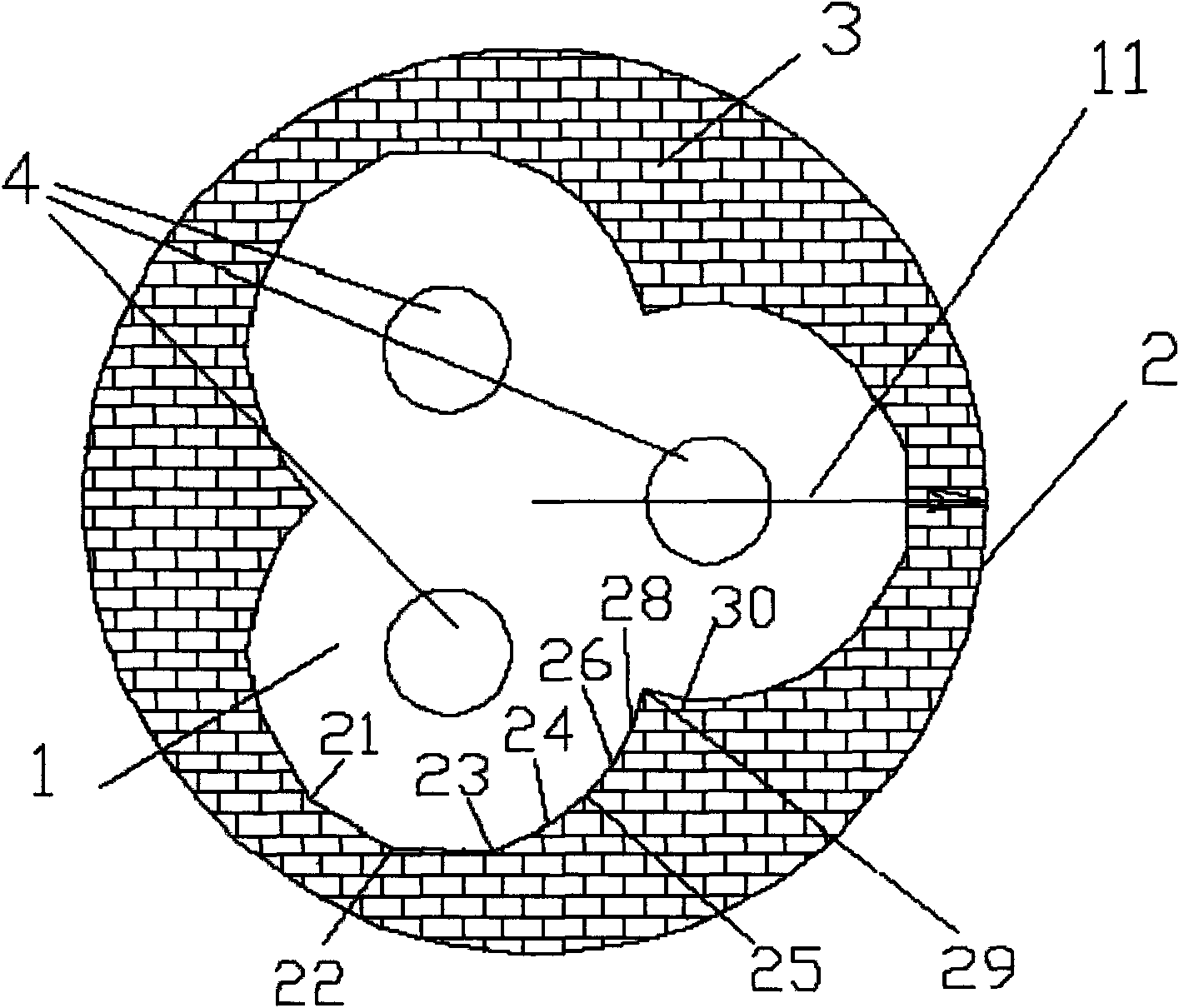

[0054] 1. The construction of the furnace shell is similar to the traditional one, only the structure of the shell coil is different. Part of the submerged arc furnace cover of the patent series can be designed and manufactured separately according to the traditional round shape or the horizontal characteristic shape of the furnace shell according to the patented invention.

[0055] 2 Furnace masonry can adopt the traditional refractory brick masonry method, only the brick structure and size are different from the traditional ones, depending on the expected design and the approach method (or transformation method) of the specific furnace shell and the approach method of the expected internal structure of the furnace. Different, the expected design of refractory bricks and different furnace wall structures are designed for the size decomposition and thickness of refractory bricks, and then production, firing, masonry, specific decomposition methods and the size of special bricks ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com