Pneumatic pressure testing device of welding arc column

A technology of pressure testing and arc column, which is applied in the direction of measuring device, measuring fluid pressure, instrument, etc., can solve the problems of lack of versatility, inability to accurately reflect the size and distribution of the pneumatic pressure of welding arc column, and achieve the purpose of preventing burning bad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

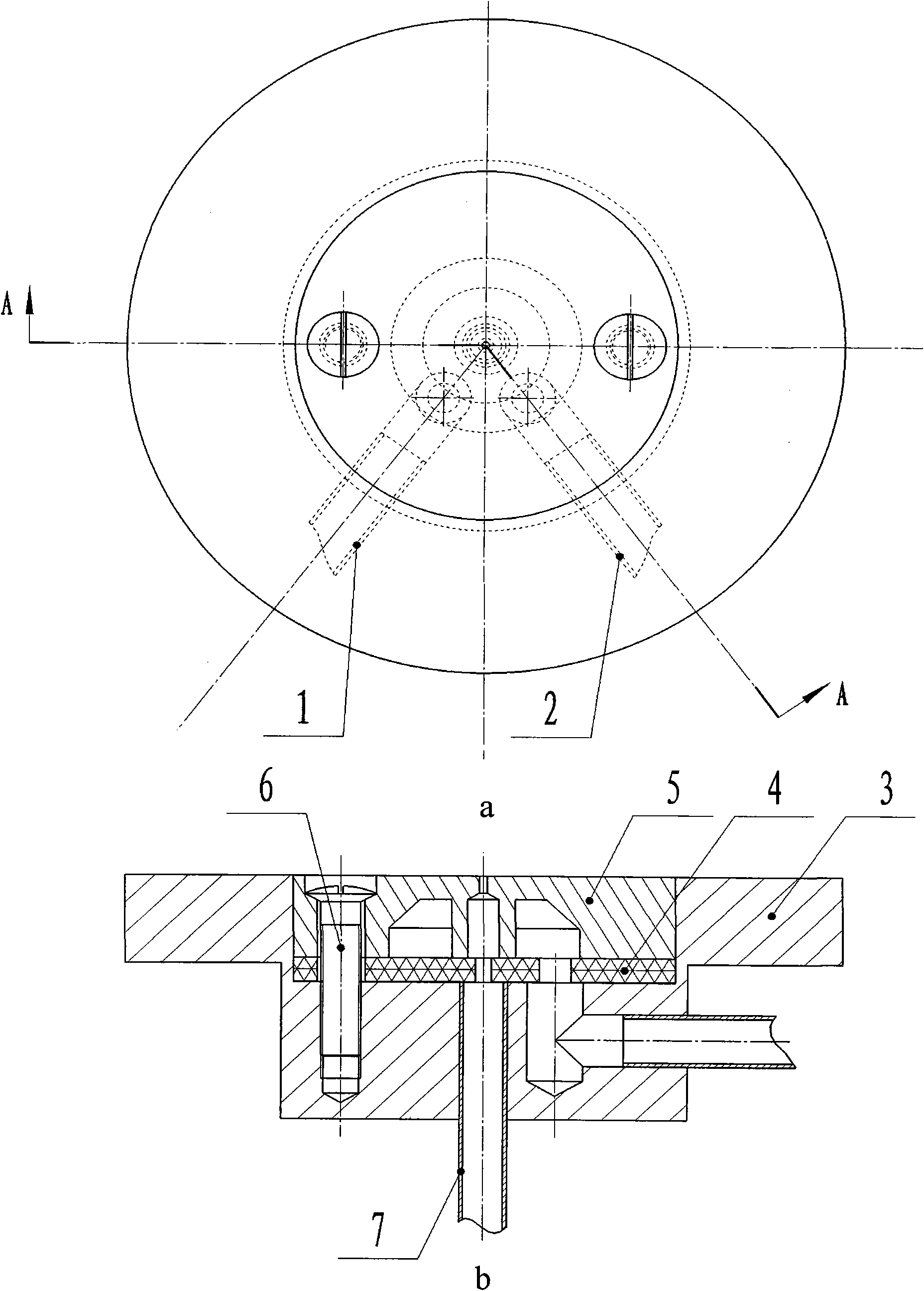

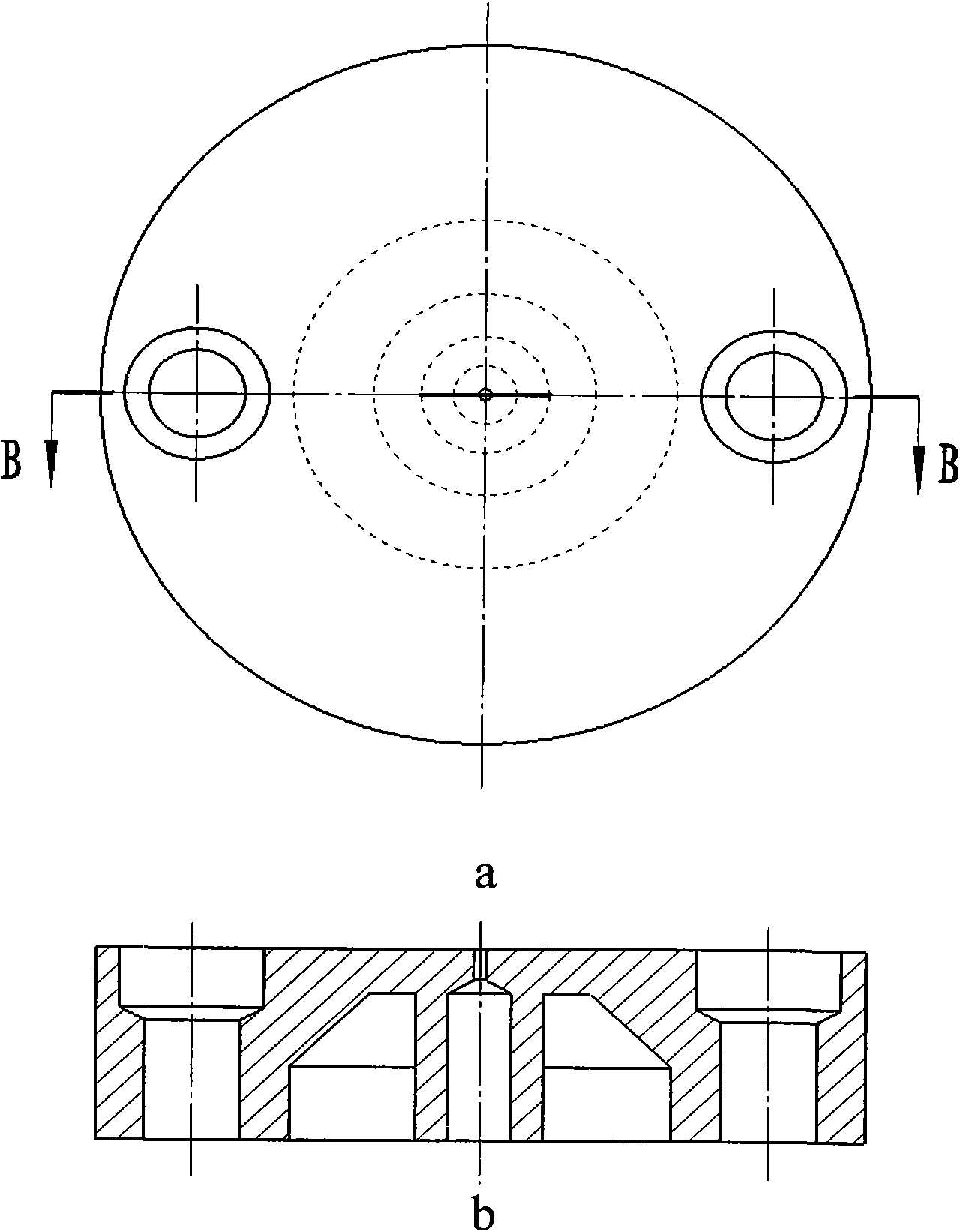

[0014] Such as figure 1 As shown, a welding arc column pneumatic pressure testing device includes a disc-shaped support 3, the upper part of which is inlaid with a water-cooled copper electrode 5, and the side of the lower round table is provided with inlet and outlet holes respectively connected to the inlet and outlet pipes 1 and 2 There is an annular groove under the water-cooled copper pole 5, and a circulating water-cooled cavity is formed between the annular groove and the recessed inlay plane on the upper part of the support, which is connected to the inlet and outlet holes. A small hole with a diameter of 0.5-0.8mm. The round table at the lower part of the support 3 is provided with a central through hole connected to a copper tube 7, one end of the copper tube is connected to the small hole in the center of the water-cooled copper pole, and the other end is connected to the pressure sensor through a hose. A sealing gasket 4 is provided between the bottom of the water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com