System and method for controlling reaction of alga

An algae and reactor technology, applied in control/regulation systems, multiple fluid ratio control, temperature control, etc., can solve the problems of difficulty in cultivating a large number of algae and inconvenience for large-scale industrial production of algae

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

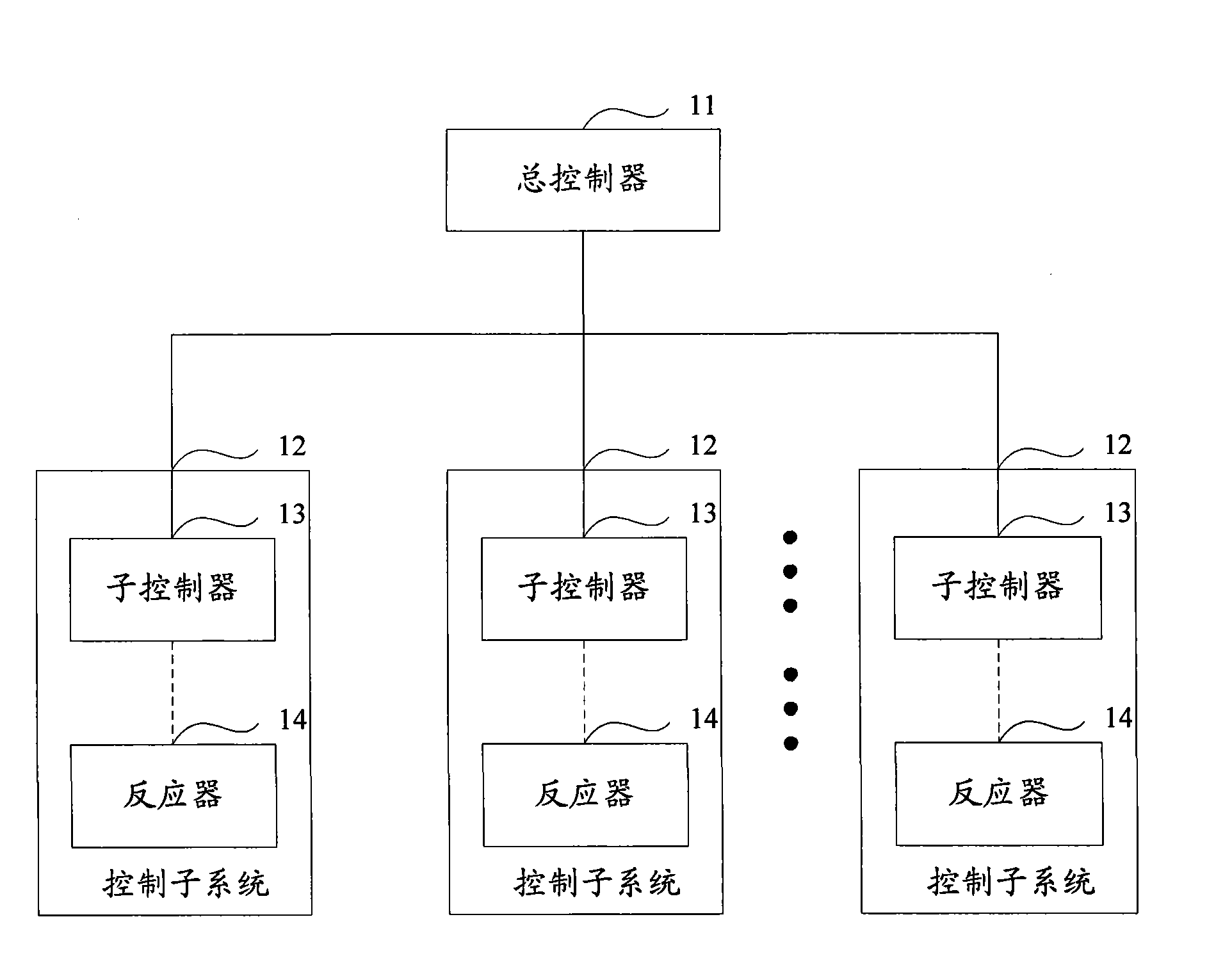

[0022] Such as figure 1 As shown, it is a schematic structural diagram of the algae reaction control system in Embodiment 1 of the present invention. The algae reaction control system in this embodiment adopts a layered distributed control structure, including a general controller 11 and multiple control subsystems 12, wherein , each group of control subsystems 12 includes a sub-controller 13 and a reactor 14 . The working process of each component in the system is as follows:

[0023] The master controller 11 is used to determine at least one environmental parameter required for the growth of the algae, the corresponding range value of each environmental parameter according to the pre-saved information about the algae cultivated in each reactor 14, and correspond the environmental parameters of the algae to The range value is sent to the sub-controller 13 of the control subsystem where the reactor 14 of the algae is cultivated; the sub-controller 13 is used to detect the env...

Embodiment 2

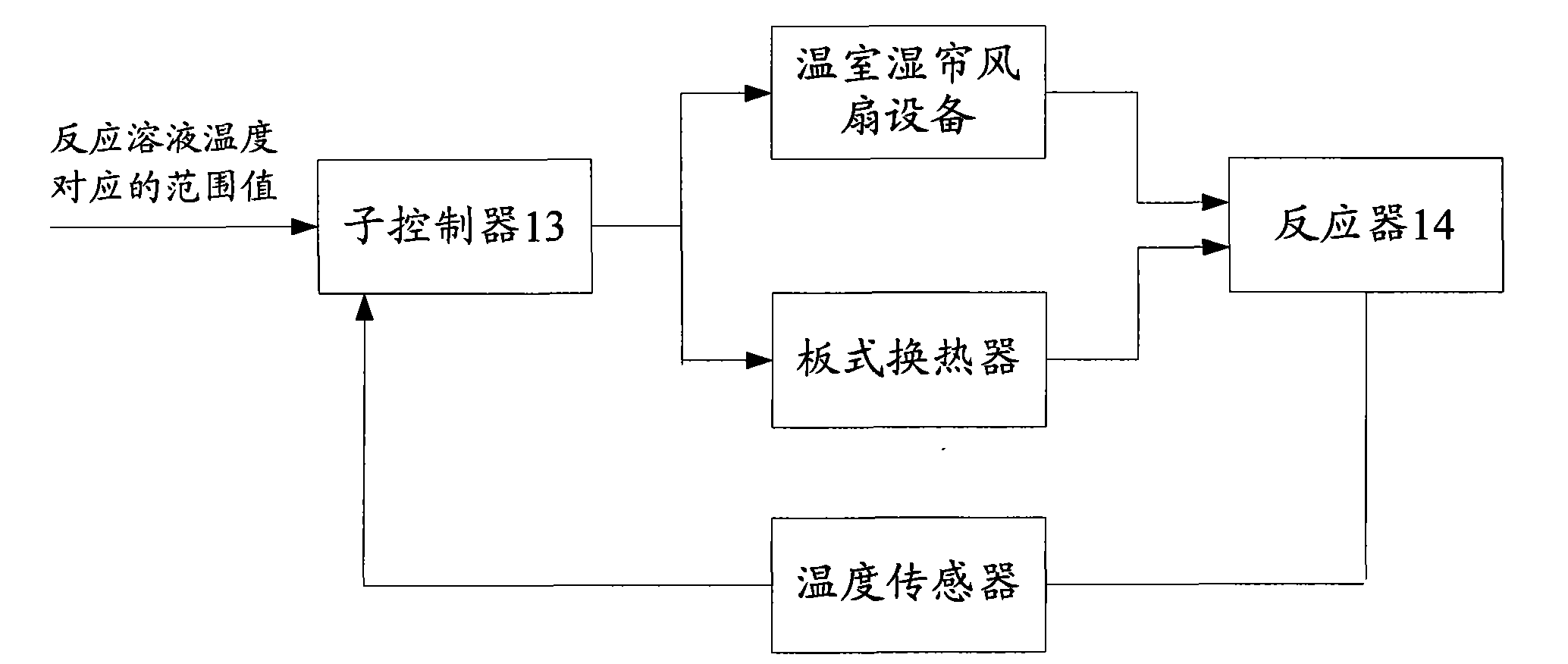

[0032] The second embodiment of the present invention is received. One of the environmental parameters is the temperature of the reaction solution as an example to illustrate the monitoring of the algae environment in the reactor 14 by the sub-controller 13 . Such as figure 2 As shown, in a group of control subsystems 12, sub-controllers 13, reactors 14, and various sensors and actuators interact with each other to complete the structural schematic diagram of temperature monitoring, assuming that the involved sub-controllers 13 and reactors 14 are devices belonging to the same control subsystem 12.

[0033] The reaction solution temperature control process is described below:

[0034] Since algae have an optimal growth temperature, the optimal growth temperature of different algae may be different, therefore, the total controller 11 should determine the corresponding ideal reaction solution temperature and the corresponding range value of the reaction solution temperature ac...

Embodiment 3

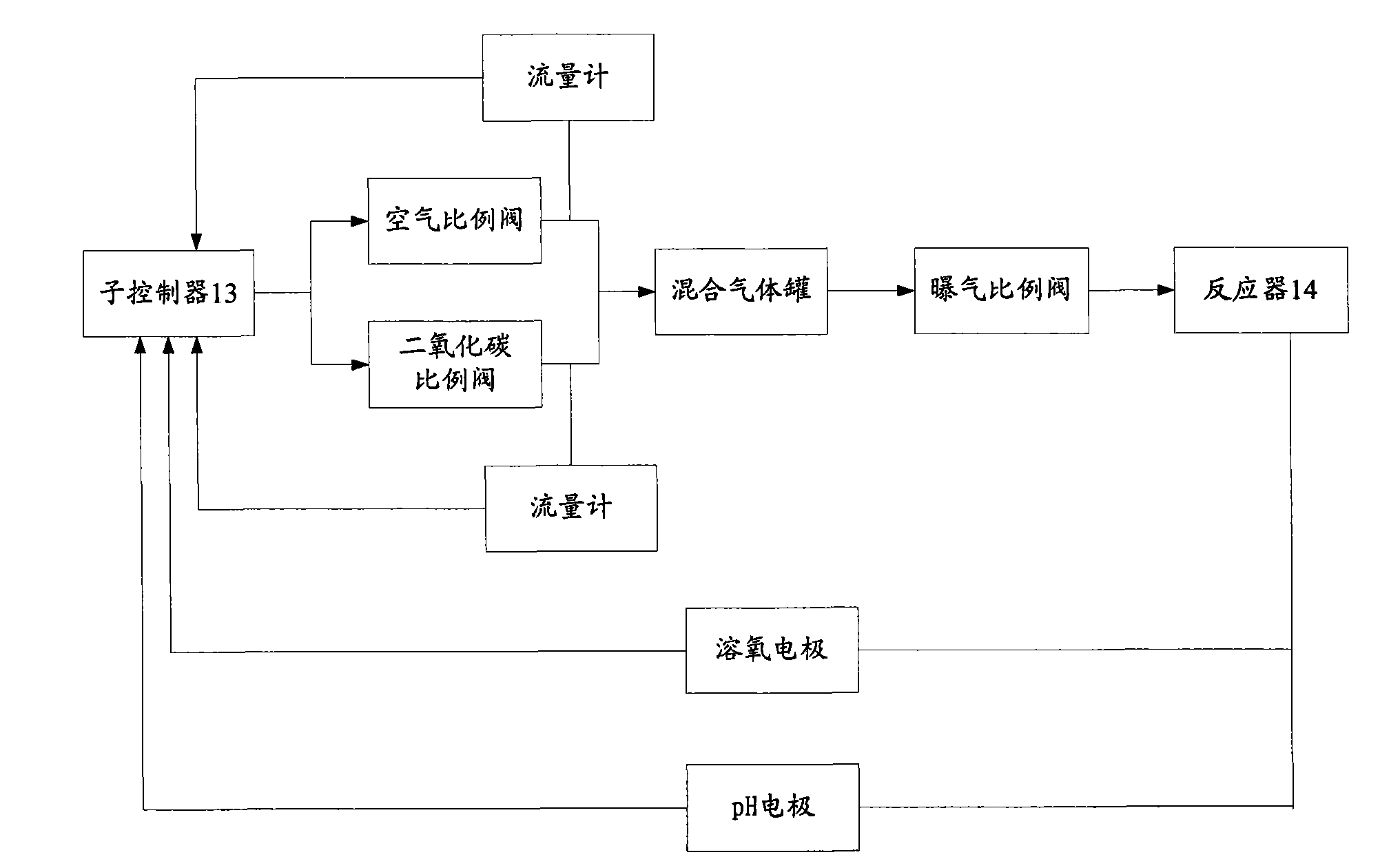

[0048] In the third embodiment of the present invention, one of the environmental parameters received is the pH of the reaction solution and the dissolved oxygen of the reaction solution as an example to illustrate the monitoring of the algae environment in the reactor 14 by the sub-controller 13 . Such as image 3 As shown, in a group of control subsystems 12, sub-controllers 13, reactors 14, various sensors, and actuators work interactively to complete the monitoring of pH and dissolved oxygen. It is assumed that the involved sub-controllers 13 and the reactor 14 are devices belonging to the same control subsystem 12 .

[0049] The pH value (i.e. pH) and the dissolved oxygen concentration (dissolved oxygen) of the culture solution are one of the important factors affecting the growth of algae. By passing into the reactor 14 acid-base substances to adjust the pH value, the reactor 14 The pH of the reaction solution meets the requirements of algae cultivation. In addition, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com