Electrical test system and method of automotive body based on CAN bus

A CAN bus and automobile body technology, applied in the field of automobile network testing, can solve the problems of low implementation efficiency, long development cycle, and inability to monitor real-time information of electronic controllers, and achieve the effects of improving efficiency, convenient operation, and shortening development time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

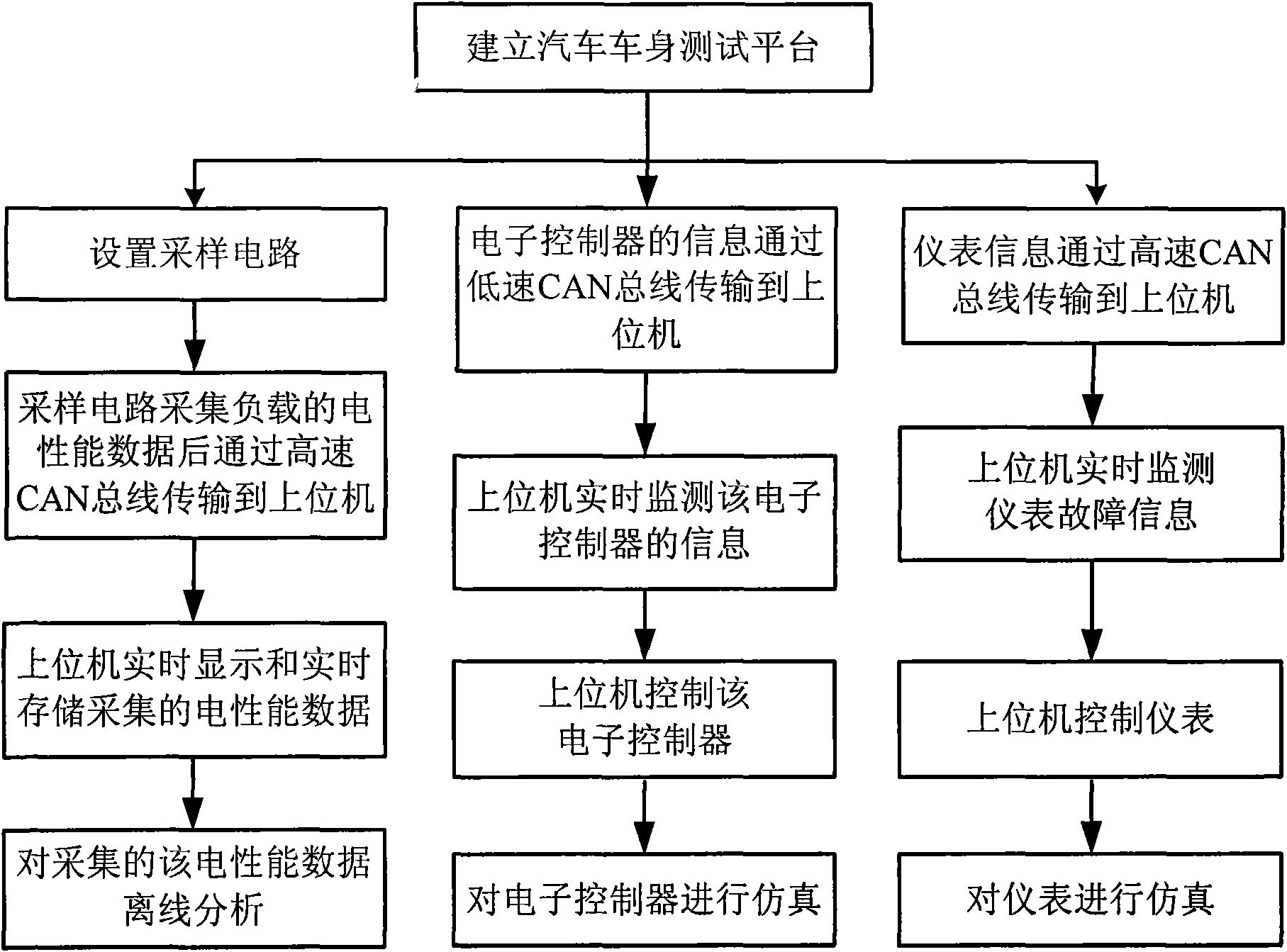

Method used

Image

Examples

Embodiment 1

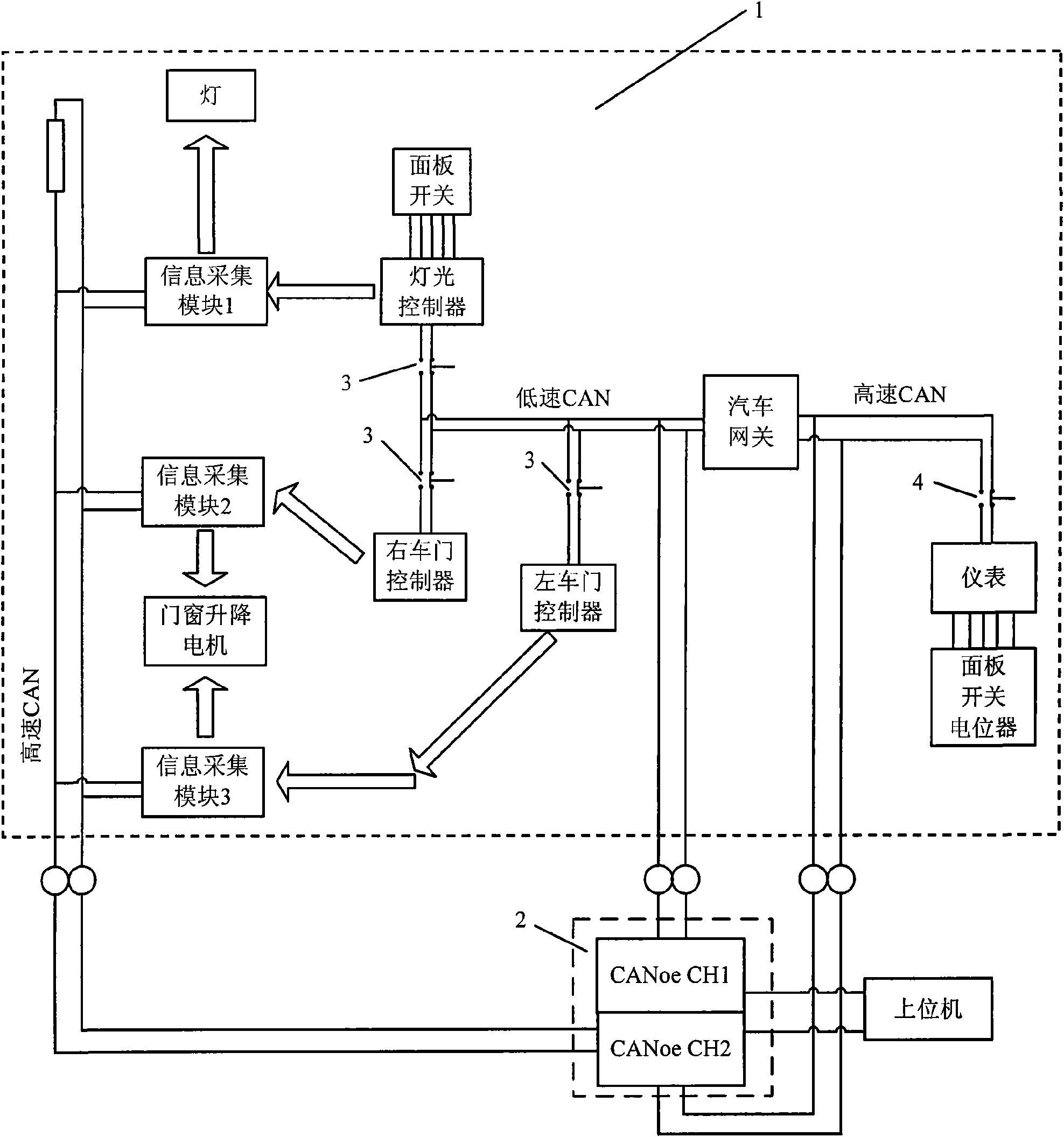

[0034] Embodiment one: the test of the electrical function of the left car door is as follows:

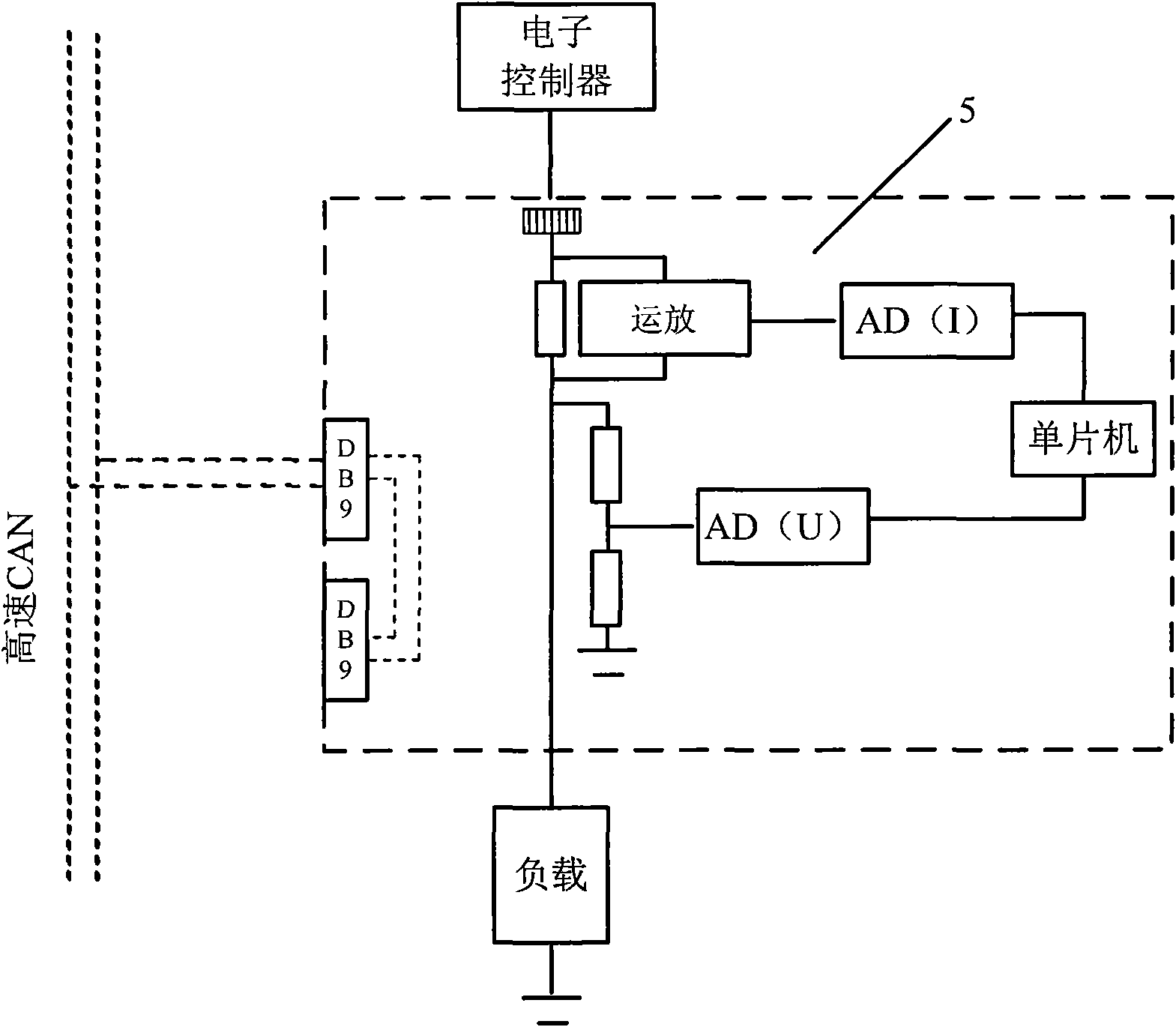

[0035] Enter the electrical function test unit in the CANoe software, operate the physical switch of the left door on the car body test platform, the switch signal is sent to the electronic controller of the left door, and the electronic controller of the left door performs corresponding operations on the door and window lifting motor. At this time, The information collection module receives the signal from the electronic controller of the left car door, and then collects the electrical performance data of the door and window lifting motor for the path where it is located. The data acquisition unit in the electrical test unit of the upper computer can display the collected data in real time in the form of charts, and store the data in the background database in real time, and at the same time, the data analysis unit calls the collected data of the database for offline analysis.

Embodiment 2

[0036] Embodiment 2: The test and simulation of the electrical function of the body light are as follows:

[0037] Enter the CAN bus simulation unit in the CANoe software, operate the simulated light switch, send a signal to the light controller according to the customized CAN2. The electrical performance data of the lamp in the channel; at this time, the upper computer selects the channel where the lamp is located, and sets the collected voltage, current range and collection frequency, and the data acquisition unit will read the data collected by the underlying hardware, store it in the database, and display it in a graph displayed in real time. The real-time information of the lighting controller can be monitored in real time through the information monitoring unit, and the node simulation unit can simulate the lighting controller. In addition, our host computer software simulates the physical load on the bench, that is, the real-time status of the object can be displayed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com