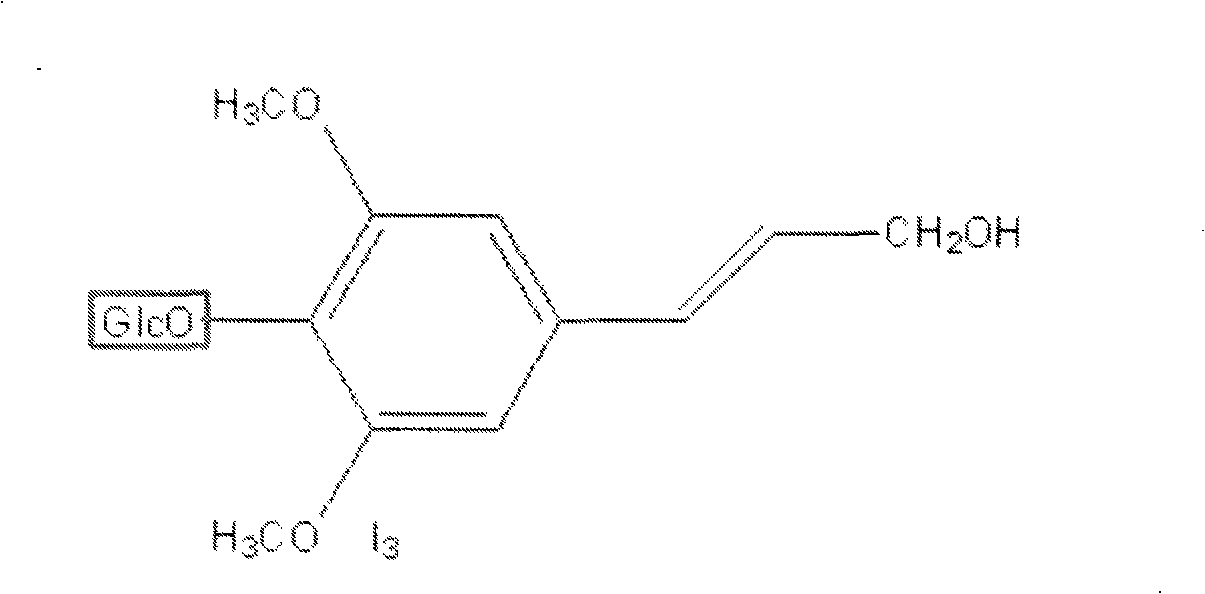

High-purity syringin, preparation method and application

A syringin and high-purity technology is applied in the field of preparation of high-purity syringin, can solve the problems of being unsuitable for industrial production and high cost, and achieve the effects of low price, less residue and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation method of high-purity syringin comprises: dissolving, macroporous adsorption resin chromatography, decolorization, macroporous adsorption resin chromatography, crystallization, and recrystallization, and is characterized in that:

[0033] a. The dissolution is to dissolve the Acanthopanax ointment with 10 to 30 times of water, then let it stand, and centrifuge;

[0034] b. The macroporous adsorption resin chromatography is to filter the centrate and then go to the macroporous resin chromatography column, first remove impurities with water, then remove impurities with low-concentration C1---C5 lower alcohols, and then use C1---C5 - Desorb the lower alcohol of C5, collect the components containing syringin in sections, and concentrate under reduced pressure;

[0035] c. decolorize the decolorized resin on the concentrated solution, and collect the part containing syringin;

[0036] d. The collected liquid is then subjected to macroporous adsorption resin ...

Embodiment 2

[0039] Take Acanthopanax extractum 200g, add 10 times of water to dissolve, then let it stand, and centrifuge. After the centrate is filtered, the liquid is placed on D101 macroporous adsorption resin. Wash with water until colorless, then remove impurities with 5 and 10% ethanol, and desorb with 20% ethanol. Fractions containing syringin were collected and concentrated under reduced pressure. D900 type decolorizing resin was applied to the concentrated solution, and the part containing syringin was collected. The collected liquid was then applied to D101 macroporous adsorption resin, removed with 10% ethanol, then removed with 15% ethanol, desorbed with 40% ethanol, collected the part with a purity greater than 85%, and evaporated to dryness under reduced pressure. Dissolve with ethanol, crystallize, then dissolve with ethanol, and recrystallize to obtain syringin with a purity of 98.56%.

Embodiment 3

[0041] Take Acanthopanax extractum 300g, add 30 times of water to dissolve, then let it stand, and centrifuge. After the centrifuge is filtered, the liquid is placed on the AB-8 macroporous adsorption resin. First wash with water until colorless, then remove impurities with 5 and 15% ethanol, and desorb with 25% ethanol. Fractions containing syringin were collected and concentrated under reduced pressure. D900 type decolorizing resin was applied to the concentrated solution, and the part containing syringin was collected. The collected solution was then applied to D101 macroporous adsorption resin, removed with 5% ethanol, then removed with 10% ethanol, desorbed with 20% ethanol, collected the fraction with a purity greater than 85%, and evaporated to dryness under reduced pressure. Dissolve with ethanol, crystallize, then dissolve with ethanol, and recrystallize to obtain syringin with a purity of 98.67%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com