Method for manufacturing air compressor moving plate

A technology of air compressor and production method, which is applied in the direction of machine/engine, rotary piston type/swing piston type pump parts, mechanical equipment, etc. Uniformity, easy breakage and other problems, to achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

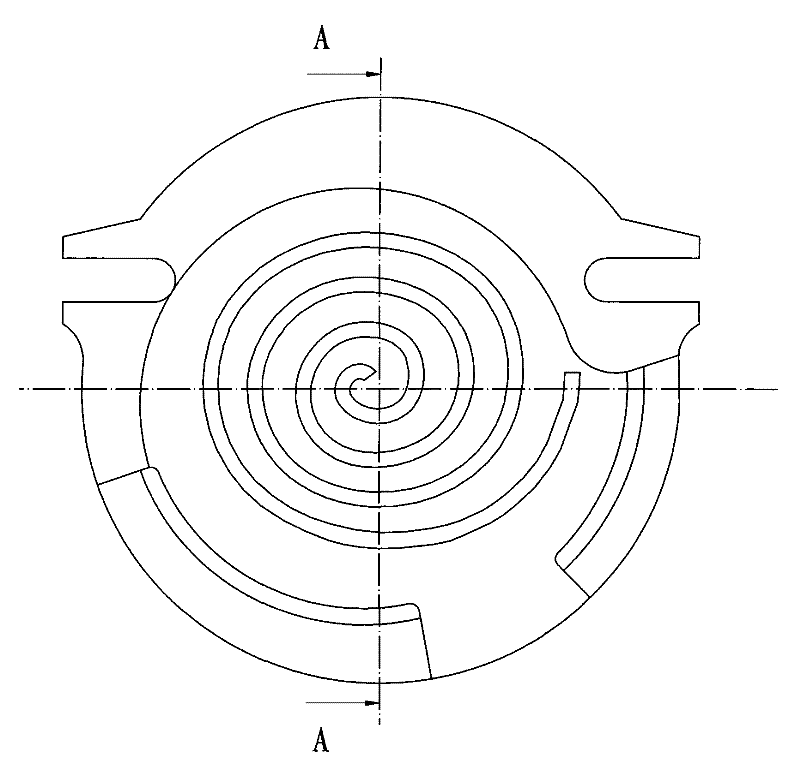

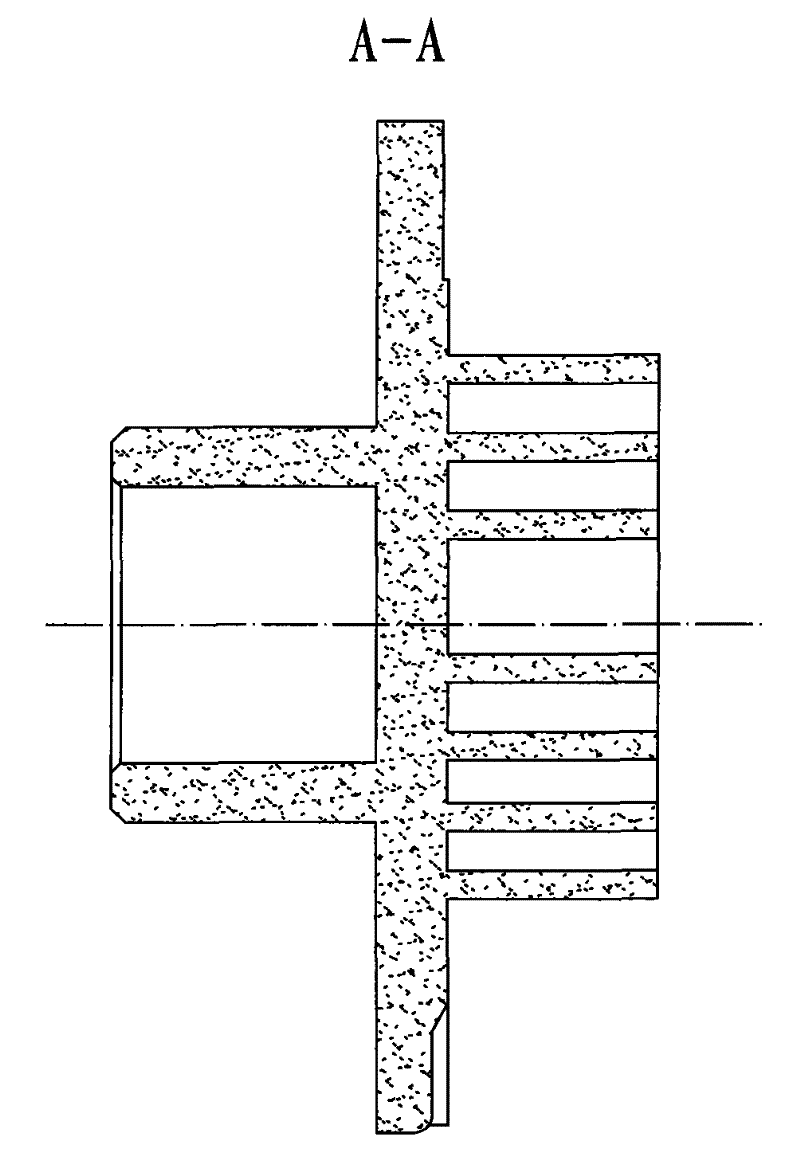

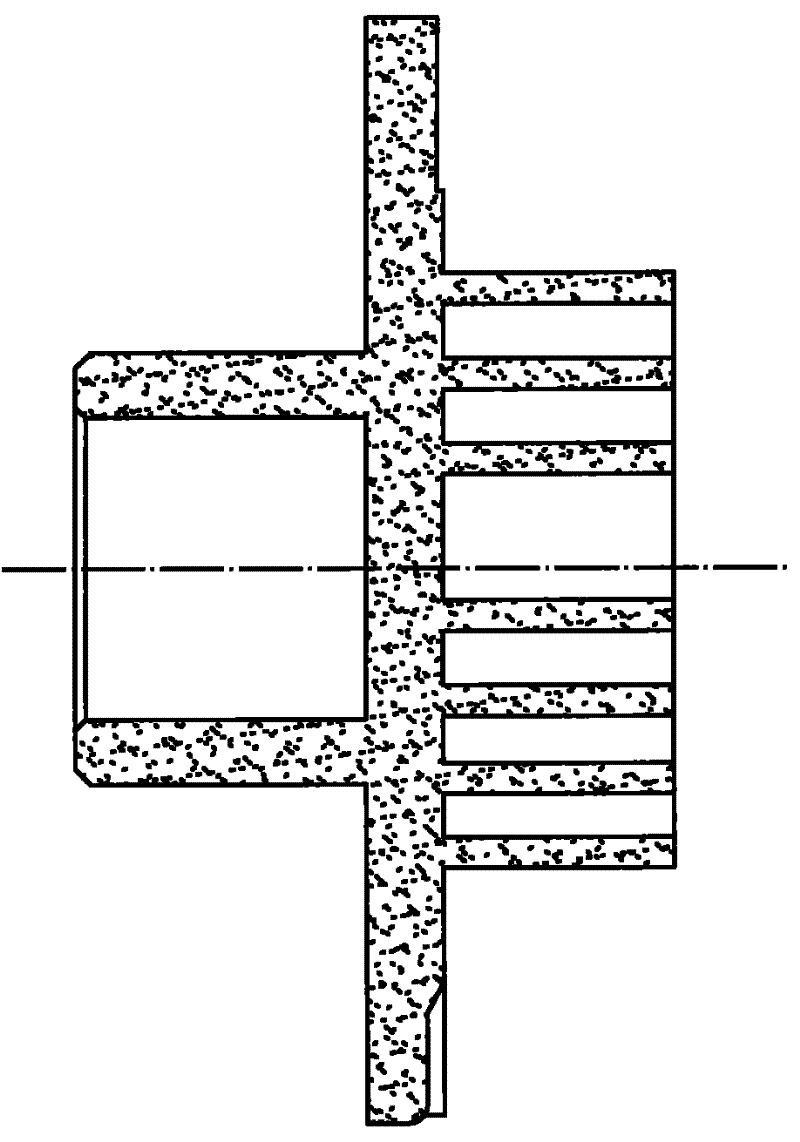

[0027] ①Mold making: Use a lathe to process the mold of the pipe body 3, use a wire cutting machine to process the mold of the spiral groove 1, and use a CNC forming machine to process the mold except the spiral groove and the remaining part of the pipe body;

[0028] ②Mixed powder: Use a mixing cylinder to mix the atomized powder and alloy powder according to the mass fraction of: 70% of atomized powder and 30% of alloy powder;

[0029] ③Pressing: Use a dry powder forming hydraulic press to press the powder mixed in step ② according to the mold prepared in step ①, and the pressure value is 1000N;

[0030] ④Sintering: Press the molded workpiece in step ③ in a sintering furnace, the sintering temperature is 1100°C, and the firing temperature is 40°C;

[0031] ⑤ Finishing: The workpiece after sintering in step ④ is ground and polished to form a finished product.

[0032] The mass fraction of the alloy powder containing iron is 90%, and the mass fraction of the alloy powder cont...

Embodiment 2

[0038] ①Mold making: Use a lathe to process the mold of the pipe body 3, use a wire cutting machine to process the mold of the spiral groove 1, and use a CNC forming machine to process the mold except the spiral groove and the remaining part of the pipe body;

[0039] ②Mixed powder: Use a mixing cylinder to mix the atomized powder and alloy powder according to the mass fraction of: 65% of atomized powder and 35% of alloy powder;

[0040] ③Pressing: Use a dry powder forming hydraulic press to press the powder mixed in step ② according to the mold prepared in step ①, and the pressure value is 800N;

[0041] ④Sintering: Press the formed workpiece in the sintering furnace sintering step ③, the sintering temperature is 1000°C, and the firing temperature is 45°C;

[0042] ⑤ Finishing: The workpiece after sintering in step ④ is ground and polished to form a finished product.

[0043] The mass fraction of the alloy powder containing iron is 92%, and the mass fraction of the alloy pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com