Antibacterial oxygen obstructing composite pipe and preparation method thereof

A technology for composite pipes and pipes, applied in the field of materials, can solve the problems of low co-extrusion surface bonding strength and delamination, and achieve the effects of good antibacterial effect, long service life and improved service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

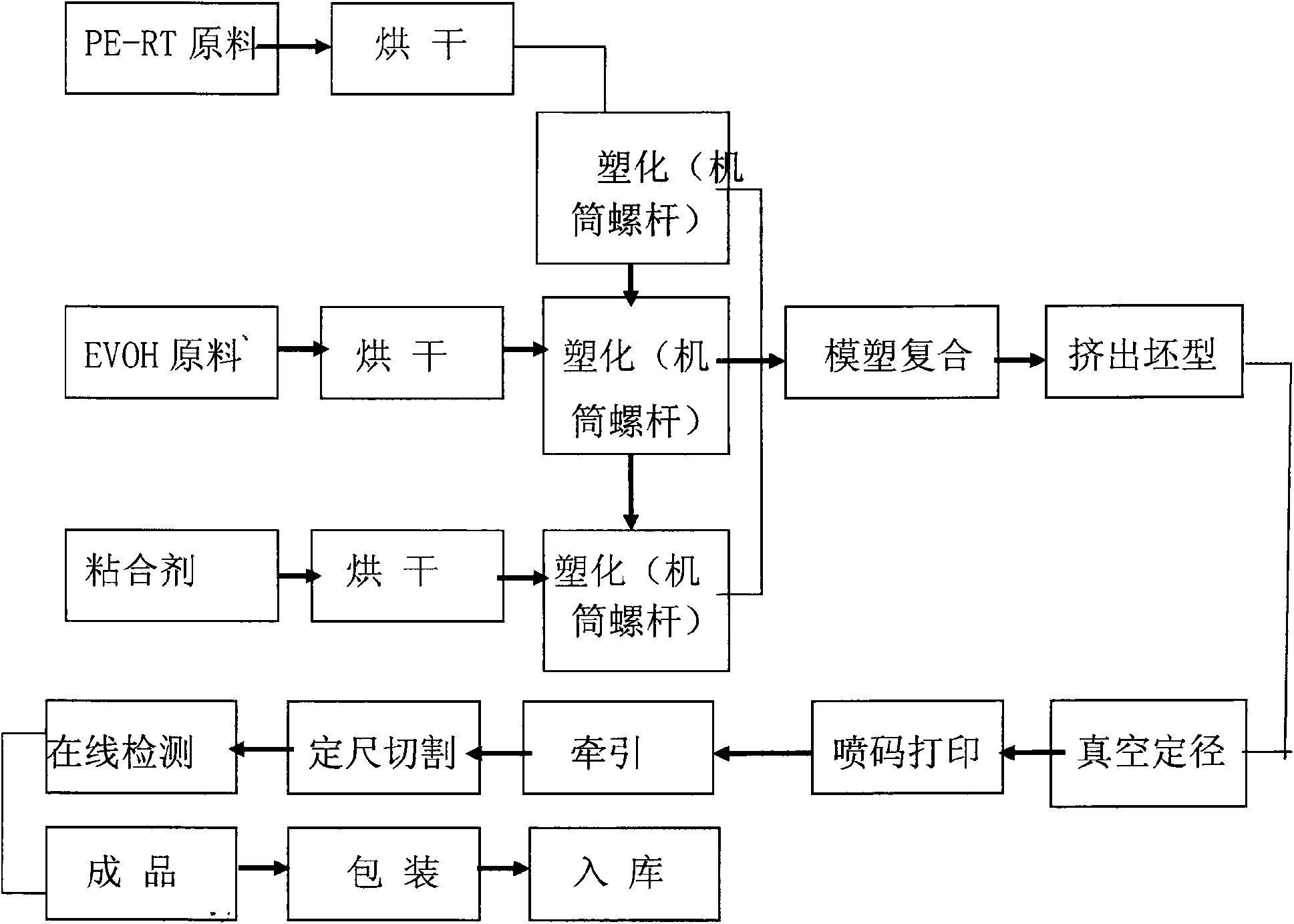

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention are described below in conjunction with the accompanying drawings.

[0029] In order to make the geothermal pipe have oxygen barrier properties, it is usually necessary to add a layer of high-barrier material in the middle or outer layer of the pipe. There are many kinds of these high-barrier polymer materials, commonly used are EVOH, PVDC, etc. EVOH. The oxygen barrier property of the PE-RT pipe coated with EVOH can reach less than 0.15mg / m2.day.atm, which can meet the requirements of the heating system to block oxygen.

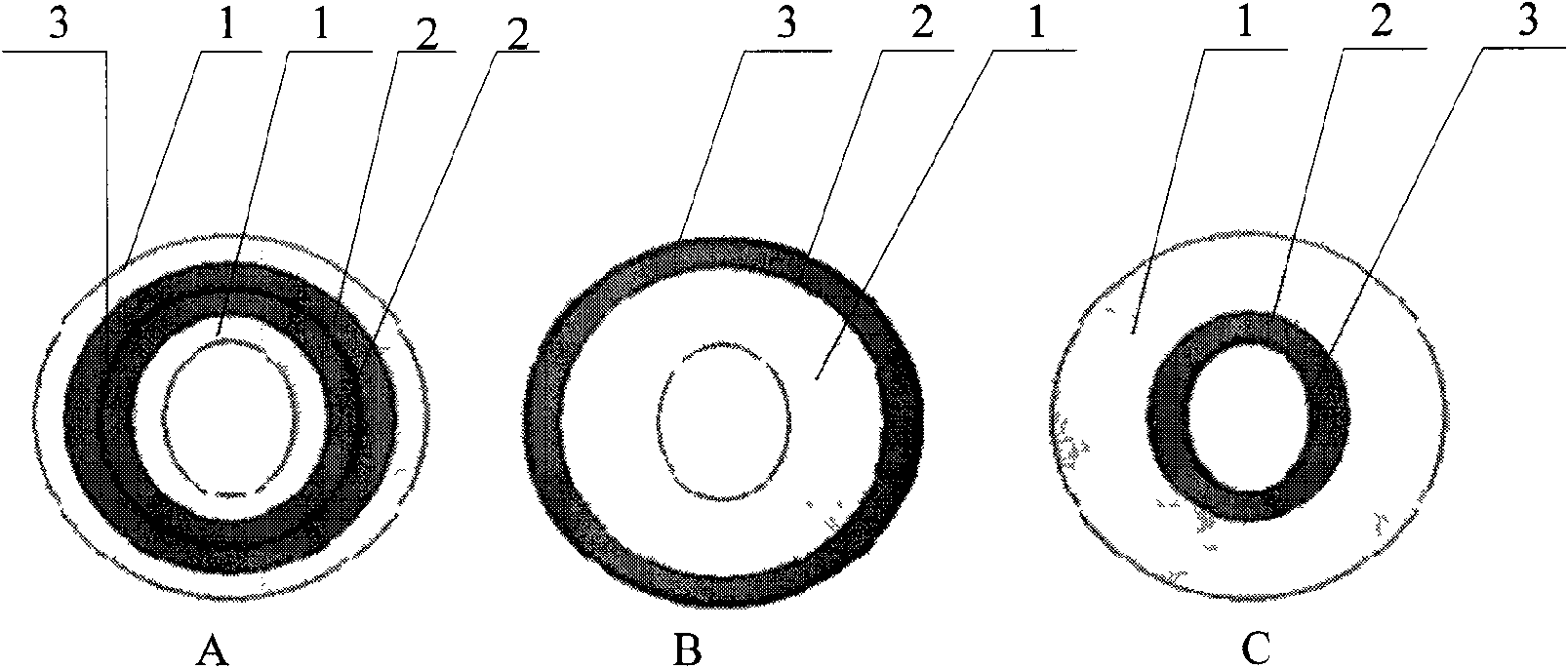

[0030] figure 1 The advantages and disadvantages of PE-RT / EVOH pipes with three different oxygen barrier positions are shown:

[0031] 1) Figure A: The advantage of the oxygen barrier layer in the middle is that it is not easy to scratch, but the processing technology is complicated and the molding is not easy.

[0032] 2) Figure B: The oxygen barrier layer is on the outer layer. Properly increase the thickness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com