Application of a viscous medium onto an electronic substrate

A technology of electronic substrates and viscous media, applied in the direction of electrical components, electrical components, etc., can solve the problem of performance reduction per unit area and achieve the effect of space reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

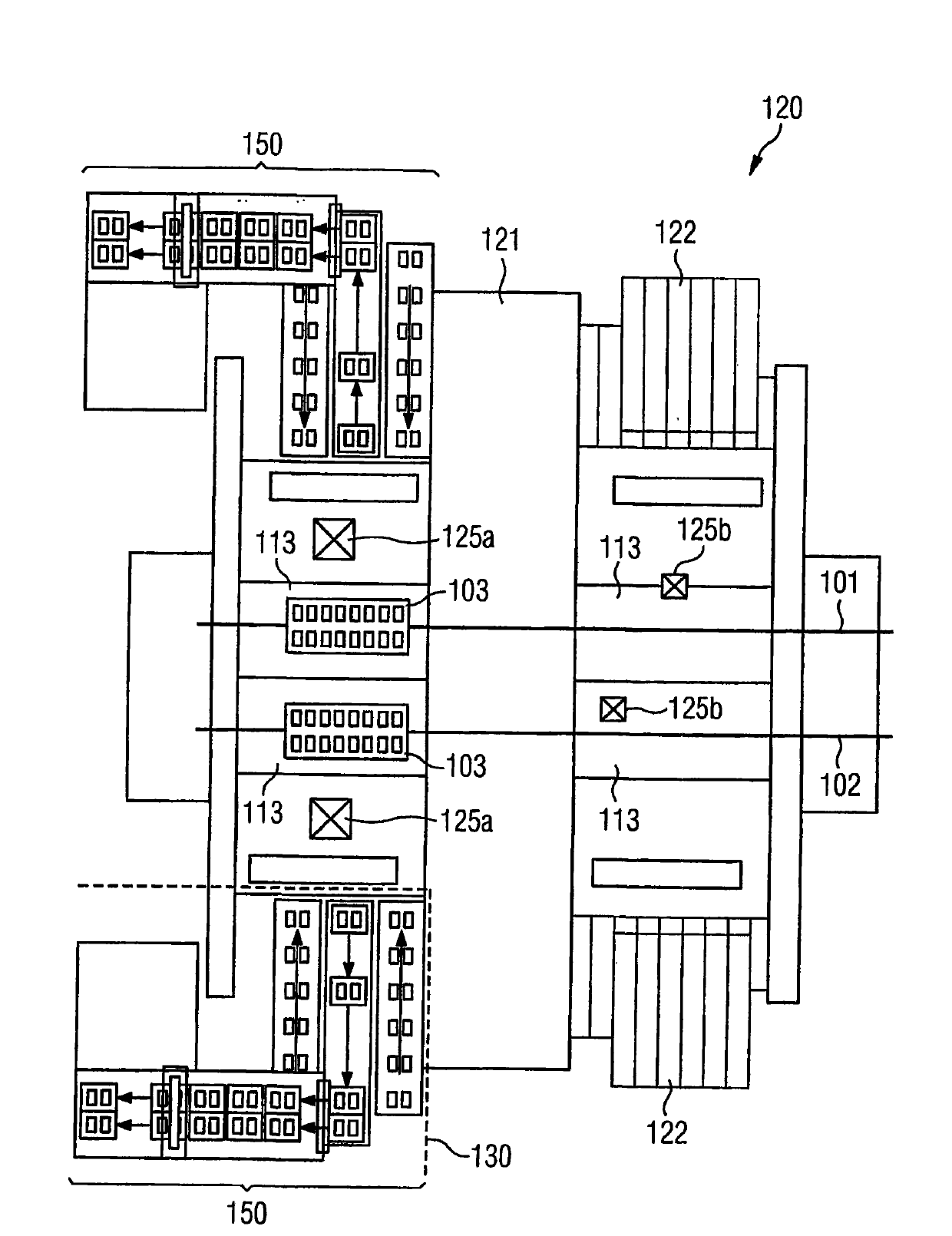

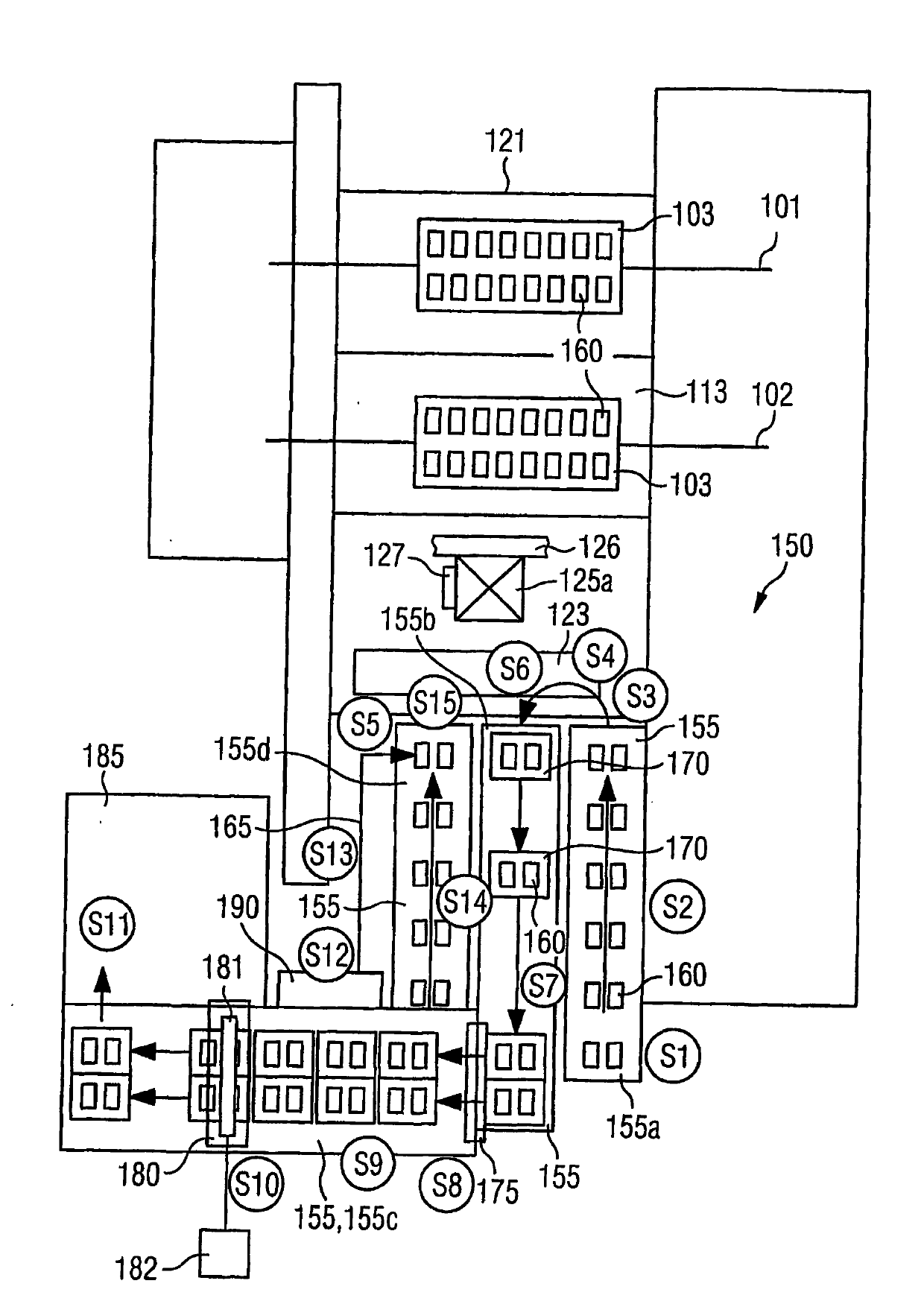

[0088] The views in the accompanying drawings are schematic. It should be pointed out that in different views, similar or identical elements are provided with the same reference signs or with reference signs which differ from the corresponding reference signs by only the first digit.

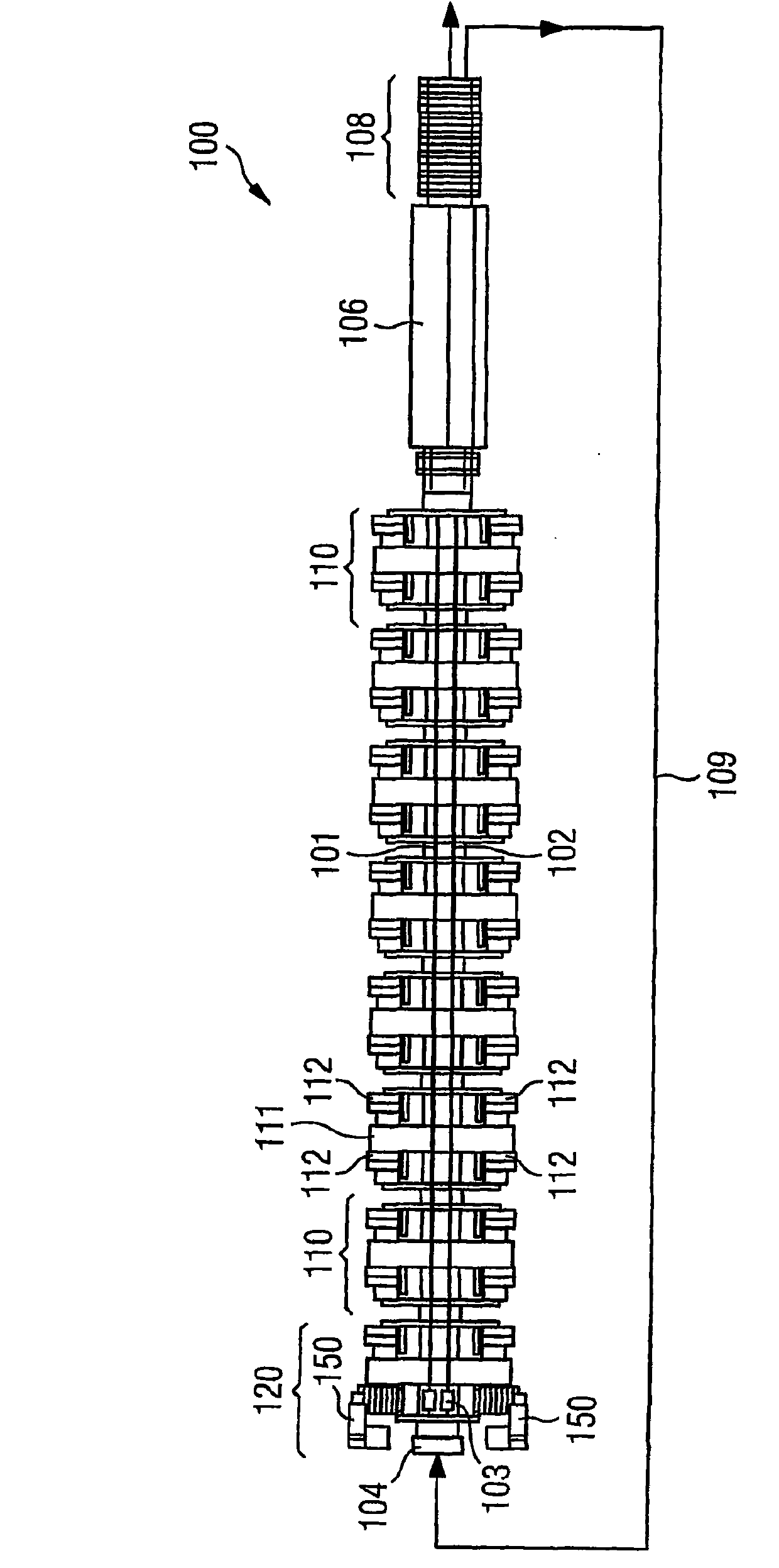

[0089] Figure 1a shows a high performance production line 100 according to an embodiment of the present invention. The production line 100 comprises a carrier loader 104 which feeds carrier elements 103 to two conveyor lines, namely a first conveyor line 101 and a second conveyor line 102 .

[0090] The production line 100 also includes a plurality of electronic component placement machines 120 , 110 arranged in a row along the two transport lines 101 and 102 . The conveying lines 101 and 102 arranged parallel to one another serve to convey the carrier element 103 . The carrier element 103 is suitable for carrying singulated electronic substrates or printed circuit boards, which have a signifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com