Material distributing technology and equipment of porcelanic ashlar texture brick

A cloth and texture technology, which is applied in the field of porcelain imitation stone texture brick cloth technology and its cloth equipment, to achieve the effect of saving polishing water consumption, strong three-dimensional effect, and rich texture patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

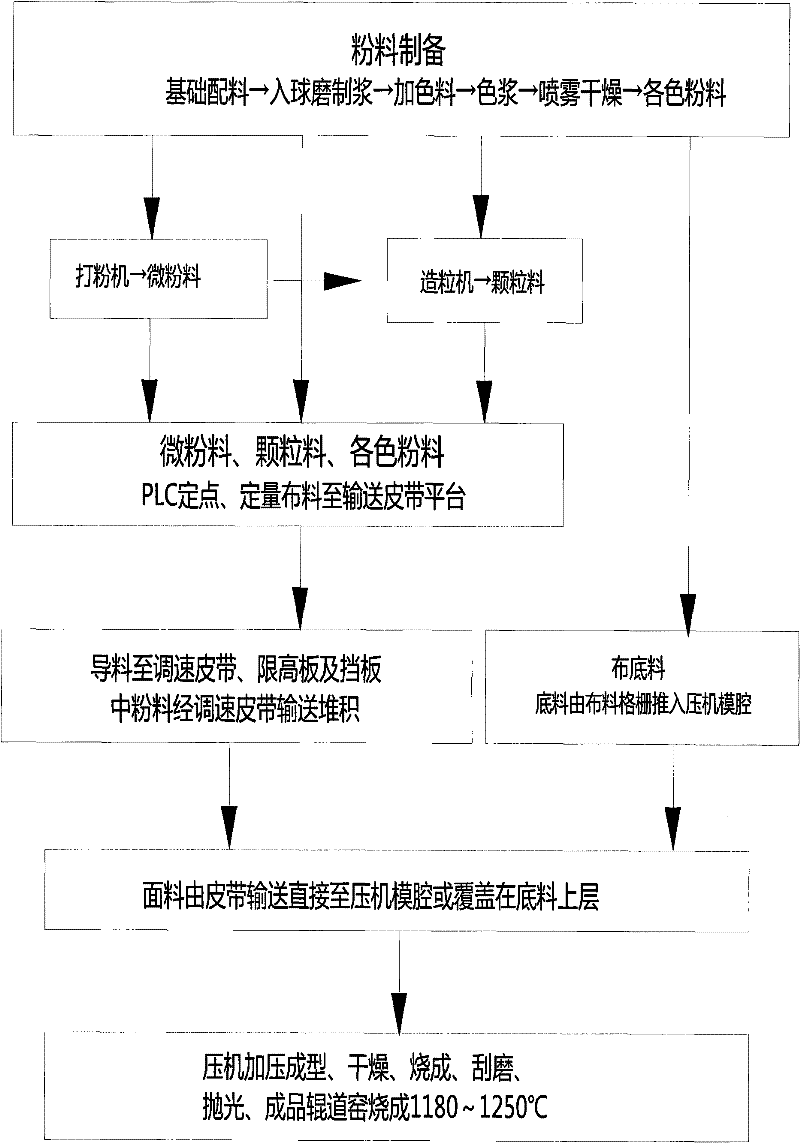

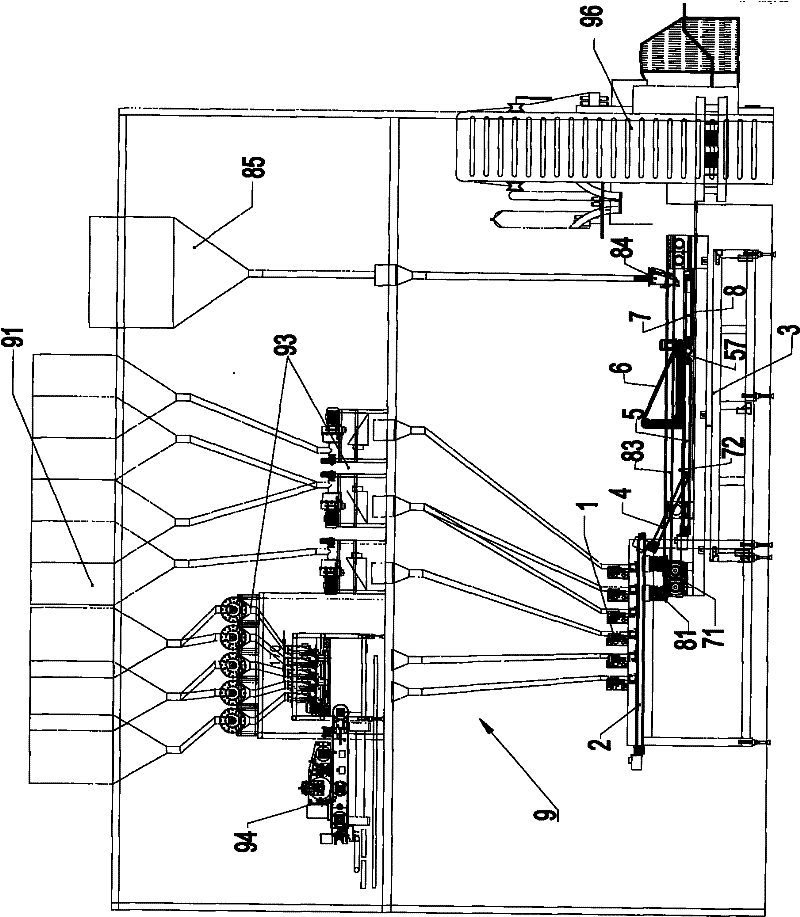

[0067] see figure 1 As shown, the cloth process of the porcelain imitation stone texture brick includes the following steps:

[0068] (1) prepare powder;

[0069] (2) The programmable controller fixed-point, quantitative distribution to the platform of the conveyor belt mechanism;

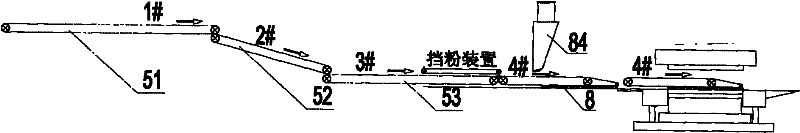

[0070] (3) The fabric is piled up horizontally by the conveyor belt mechanism to form a texture;

[0071] (4) The texture remains unchanged and delivered to the cavity of the press;

[0072] (5) Press and form into adobe with natural marble texture.

Embodiment 2

[0074] see figure 1 As shown, the cloth process of the porcelain imitation stone texture brick includes the following steps:

[0075] (1) prepare powder;

[0076] (2) The programmable controller fixed-point, quantitative distribution to the platform of the conveyor belt mechanism;

[0077] (3) The fabric is piled up horizontally by the conveyor belt mechanism to form a texture;

[0078] (4) The formed texture is delivered to the die cavity of the press without change, and covered on the upper layer of the base material pushed into the die cavity of the press through the cloth grid;

[0079] (5) Press and form into adobe with natural marble texture.

[0080] Specific process:

[0081] (1) According to the formula, the slurry is ground by a ball mill; the slurry is spray-dried to make a granular powder with a moisture content of 5% to 13%; each color powder is added to the base slurry, mixed and stirred , made into powders of various colors by spray drying;

[0082] (2) Mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com