Method for floating tubular member by airbags

A technology of tubular members and airbags, which is applied in the directions of transportation and packaging, ships, special-purpose vessels, etc., can solve the problems of low efficiency, difficult transportation in shallow water areas, and occupied resources, etc., and achieves the effect of high efficiency and low transportation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

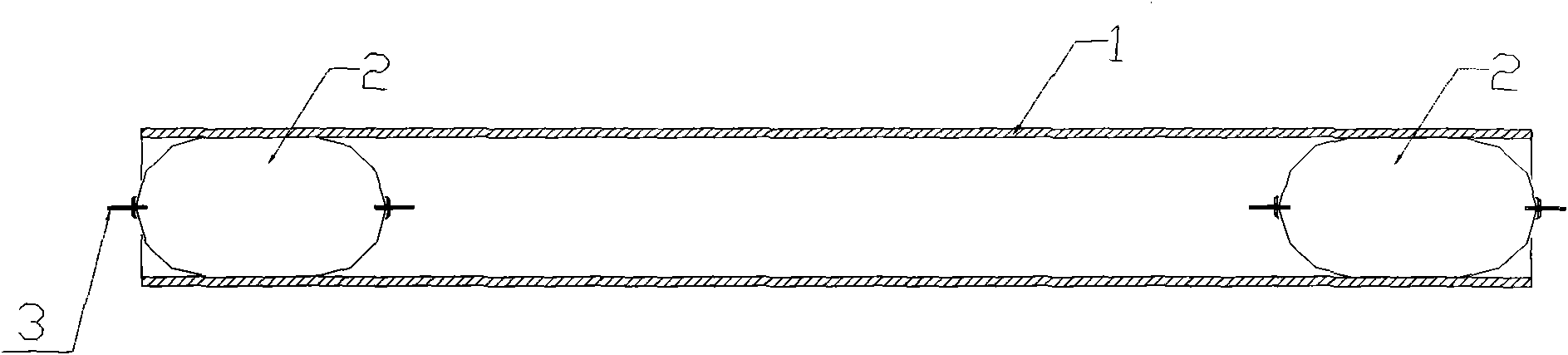

[0028] Example 1, such as figure 1 As shown, the method of floating steel pipe piles. The inner diameter of the steel pipe pile is 2.75m, and the two ends of the inner cavity of the steel pipe pile 1 are filled with oval-shaped sealing airbags 2. The total length of the airbag 2 is 3.3m, and the nominal diameter of the airbag 2 is 2.75m. The length-to-diameter ratio is 1.2. When not inflated, the perimeter of the airbag is 6.9m, which is 80% of the inner perimeter of the steel pipe pile; the working pressure of the airbag is 0.5MPa, and the airbag 2 is inflated through the airbag mouth 3, and the airbag 2 is filled At this time, both ends of the inner cavity of the steel pipe pile 1 are completely closed, and the steel pipe pile 1 is rolled horizontally into the water by using the terrain conditions of the water bank. When launching into the water, the steel pipe pile 1 floats on the water surface, and a plurality of such steel pipe piles 1 are connected together, and are pul...

Embodiment 2

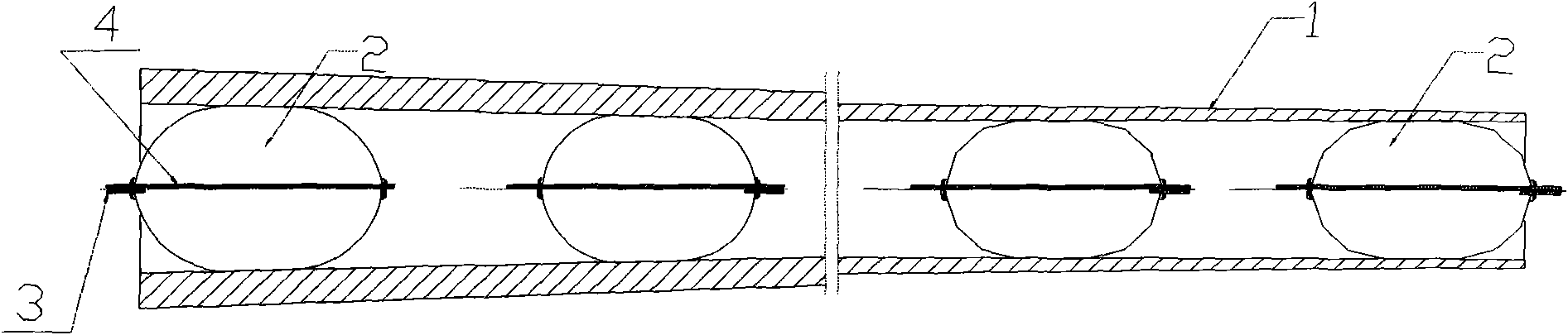

[0029] Example 2, such as figure 2 As shown, the super-heavy and super-long water intake pipe 1 with unequal cross-section has a length of 300m and a weight of 450t. The inner cavity of the water intake pipe 1 is divided into three compartments, each air bag 2 has an air bag nozzle 3 and a through-heart tube 4, and the air bag 2 inside is supplied and exhausted by the through-heart tube 4, and can also pass through the through-heart tube 4 Adjust the ballast water to each cabin, the total length of the air bag 2 is 4.8m, the diameter is 1.2, 1.5, 2m, and the working pressure is 0.15MPa to ensure the draft of the water intake pipe 1 when floating. The ramp can be used to send the water intake pipe 1 into the water by using a moving air bag or a rail block, and the water intake pipe 1 can also be moved to a low position when the tide is low, so that it can float when the tide rises. It is towed to the construction site by a tugboat.

Embodiment 3

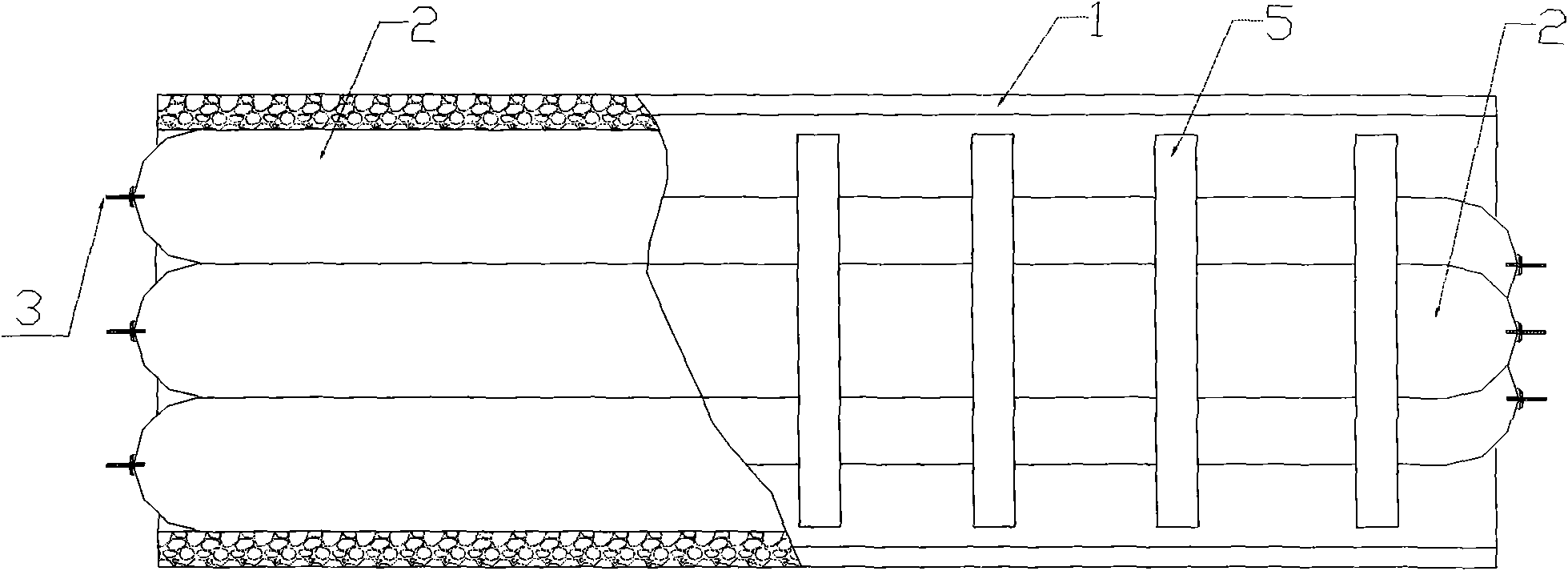

[0030] Example 3, such as image 3 , 4 As shown, the method of floating underwater tunnel immersed pipe. The cavity of the tunnel immersed tube 1 is taken as a rectangle of 5×7m, with a length of 40m and a weight of 2350t. Twelve filled airbags 2 are used to penetrate the inner cavity of the tunnel immersed tube 1. The total length of the airbags 2 is 44m, and 2m are respectively exposed from both ends of the tunnel immersed tube 1. The diameter of the airbags is 2m, and the aspect ratio is 22; The total cross-sectional area of the airbag is 37.7m 2 , which is 7.7% larger than the cross-sectional area of the cavity of the tunnel immersed tube 1; the working pressure is 0.05MPa. The draft of the tunnel immersed tube 1 filled with airbags is too large, and three buoyancy-supporting airbags 2 are bound on both sides of the tunnel immersed tube 1. The length of the airbags 2 is 44m, the diameter is 2m, and the working pressure is 0.25MPa. The binding belt 5 is flat Shaped,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com