Method for extracting chlorophyll from spirulina by using supercritical fluid

A technology of supercritical fluid and spirulina, applied in the field of separation, can solve the problems of large chlorophyll loss, high extraction temperature and low extraction yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

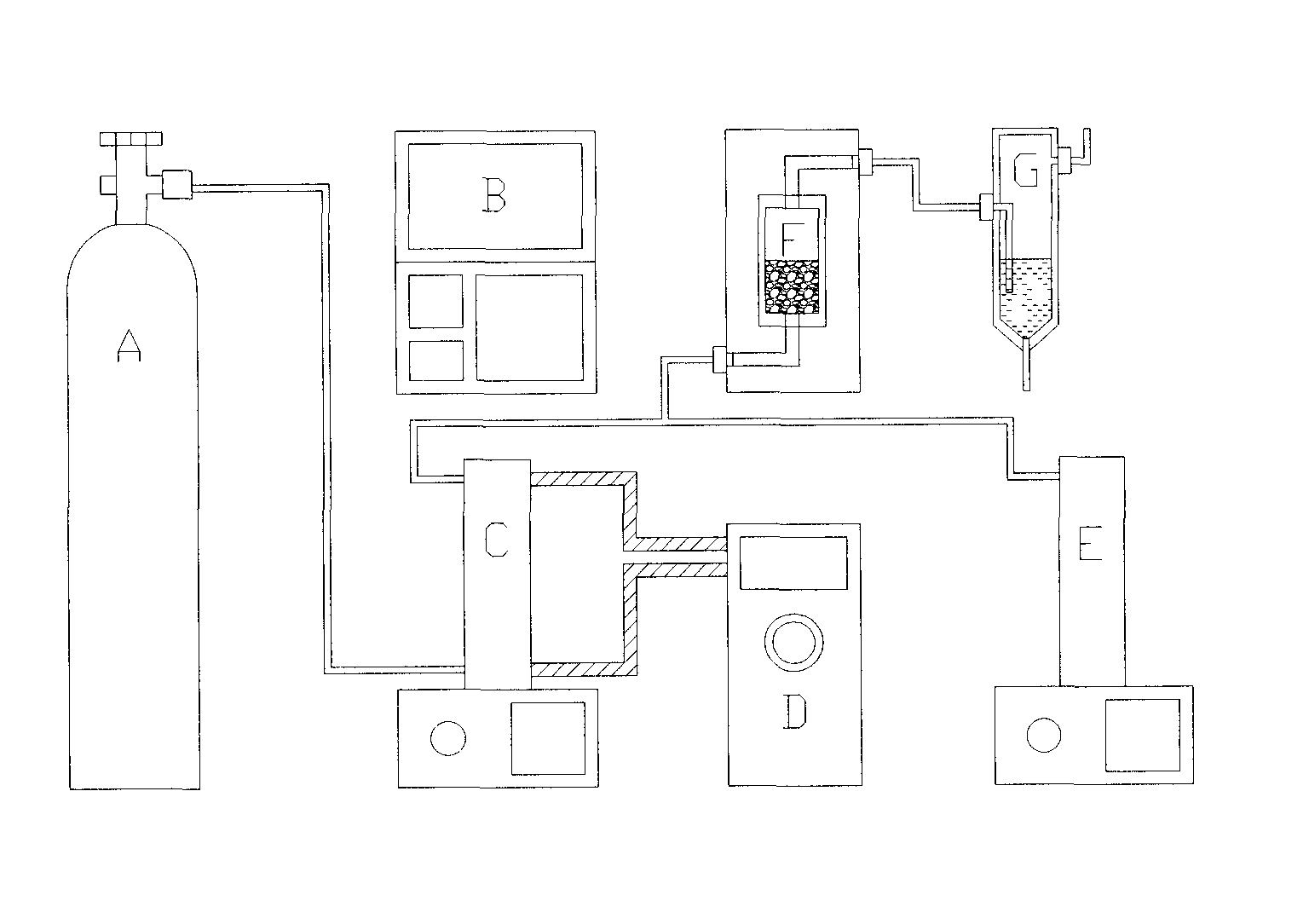

[0018] Put the spirulina powder into the extraction kettle F, input carbon dioxide into the extraction kettle F through the steel cylinder A, control the extraction conditions by using the control system B, in which the pressure is increased to 25Mpa by the high-pressure pump C, and the temperature is set by the temperature control system D The temperature is 50°C, the flow rate of carbon dioxide is 60g / h, extract for 5 hours, and use high-pressure pump E to add absolute ethanol as entrainer in the extractor. The amount of entrainer is 0.15L of absolute ethanol per gram of raw material. Chlorophyll is obtained in device G. Chlorophyll was measured by spectrophotometry, and the yield of chlorophyll was 0.89%, wherein the concentration of chlorophyll a accounted for 78% of the total chlorophyll concentration, and the concentration of chlorophyll b accounted for 22% of the total chlorophyll concentration.

Embodiment 2

[0020] Put the spirulina powder into the extraction kettle F, input carbon dioxide into the extraction kettle F through the steel cylinder A, control the extraction conditions by using the control system B, in which the pressure is increased to 30Mpa by the high-pressure pump C, and the temperature is set by the temperature control system D The temperature is 55°C, the flow rate of carbon dioxide is 100g / h, extract for 4 hours, add absolute ethanol as entrainer in the extractor with high-pressure pump E, and the amount of entrainer is 0.2L of absolute ethanol per gram of raw material. Chlorophyll is obtained in device G. Chlorophyll was measured by spectrophotometry, and the yield of chlorophyll was 1.02%, wherein the concentration of chlorophyll a accounted for 80% of the total chlorophyll concentration, and the concentration of chlorophyll b accounted for 20% of the total chlorophyll concentration.

Embodiment 3

[0022] Put the spirulina powder into the extraction kettle F, input carbon dioxide into the extraction kettle F through the steel cylinder A, control the extraction conditions by using the control system B, in which the pressure is increased to 40Mpa by the high-pressure pump C, and the temperature is set by the temperature control system D The temperature is 50°C, the flow rate of carbon dioxide is 120g / h, extract for 5 hours, and use high-pressure pump E to add absolute ethanol as entrainer in the extractor. The amount of entrainer is 0.25L of absolute ethanol per gram of raw material. Chlorophyll is obtained in device G. Chlorophyll was measured by spectrophotometry, and the yield of chlorophyll was 1.19%, in which the concentration of chlorophyll a accounted for 81% of the total chlorophyll concentration, and the concentration of chlorophyll b accounted for 19% of the total chlorophyll concentration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com