Starch paste mixer for brewing beers

A technology of starch mixing and beer, which is applied in the direction of beer brewing, etc., can solve the problems of complex structure, long mixing time, and large space occupation, and achieve the effect of compact equipment structure, no hygienic dead corners, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

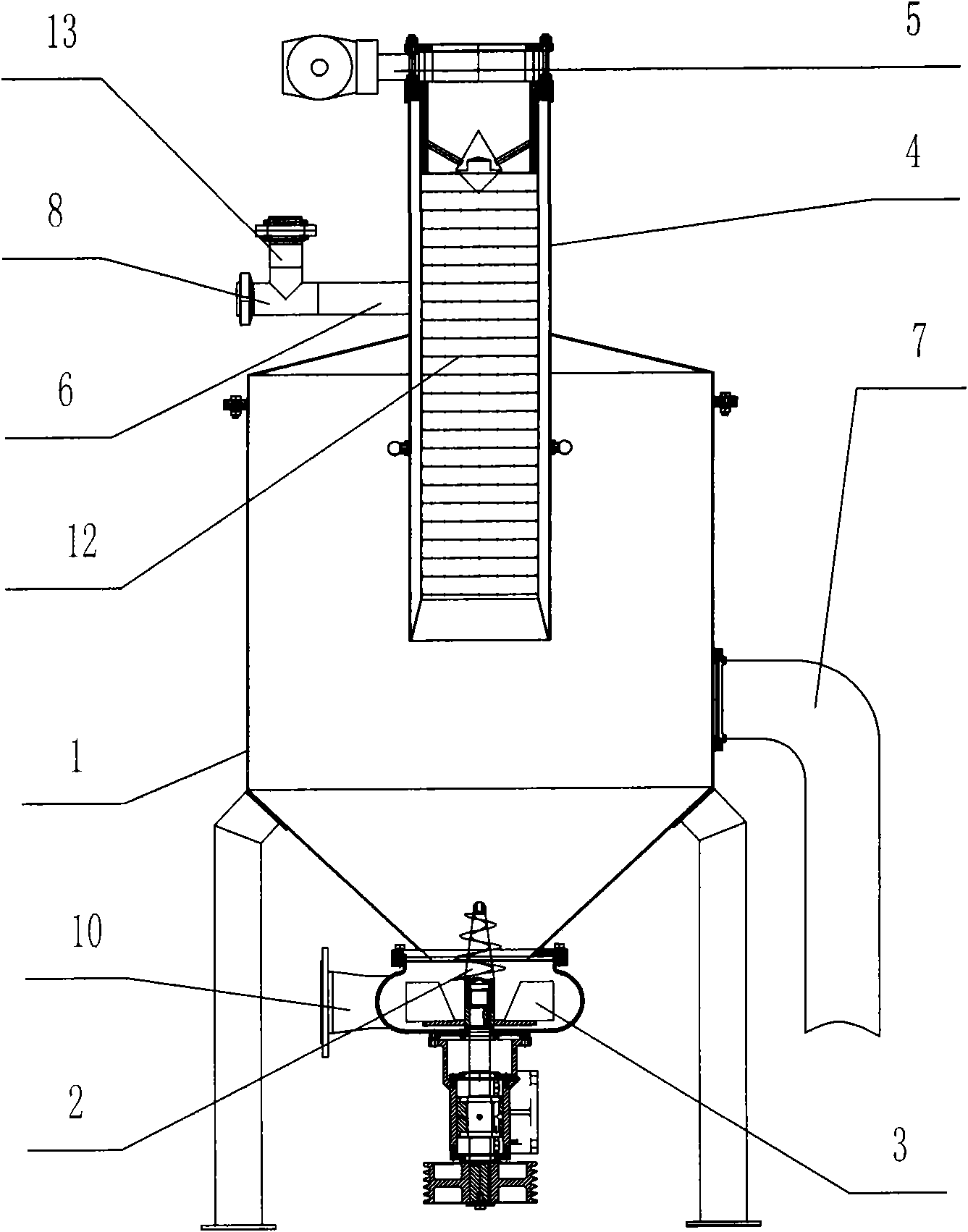

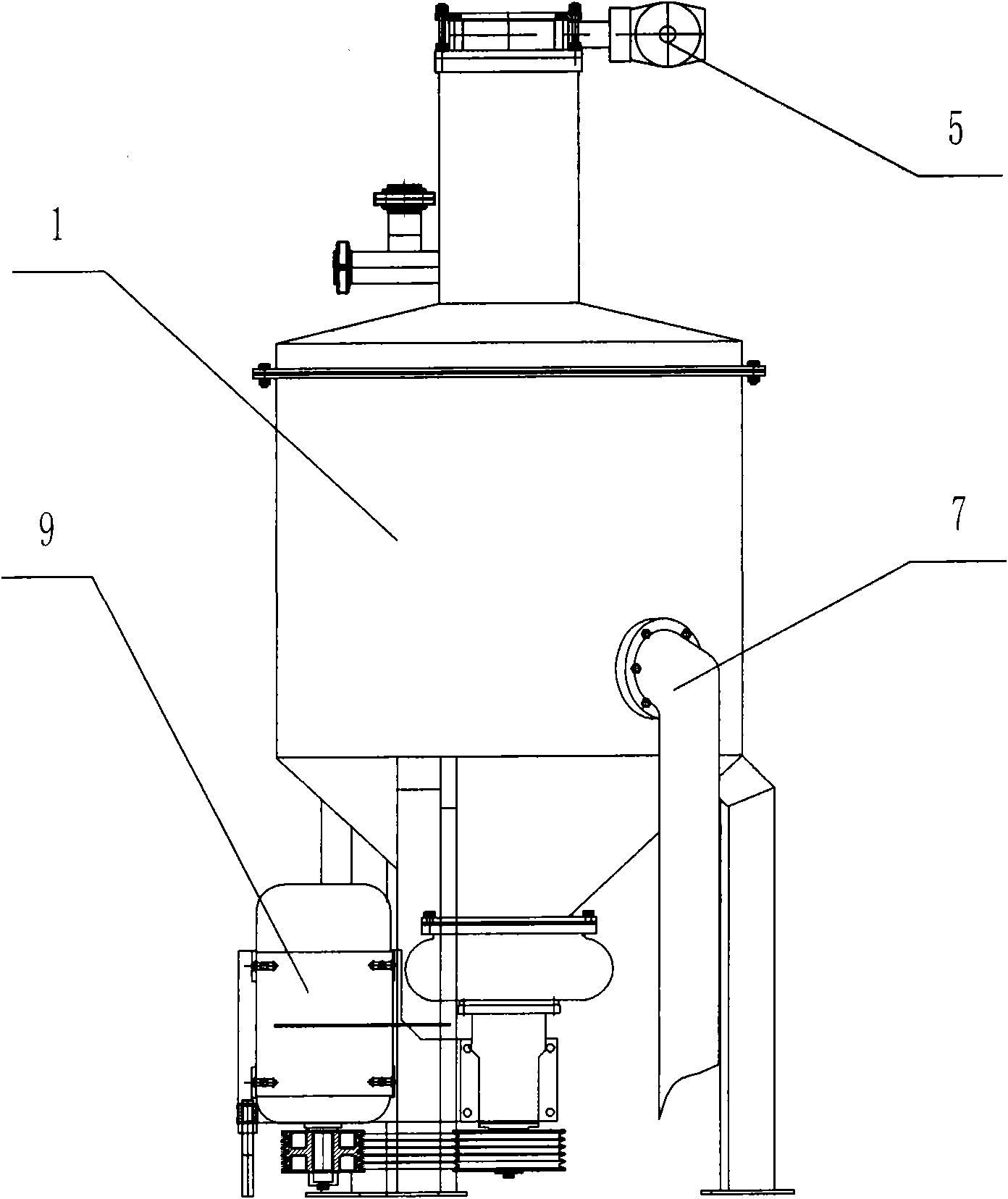

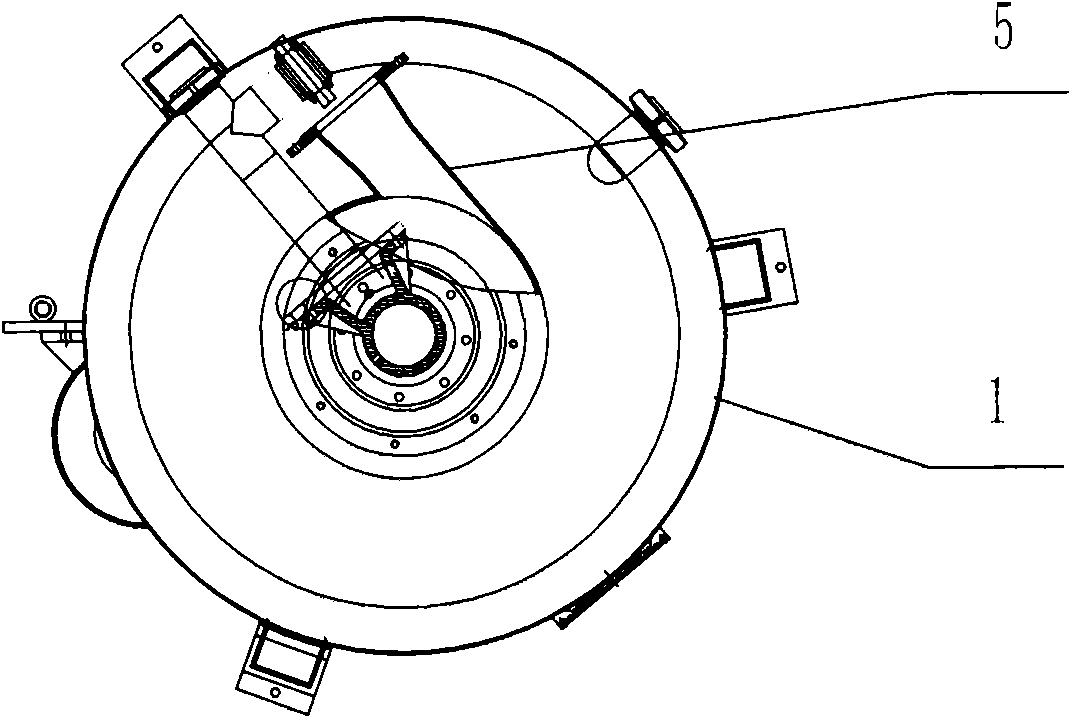

[0016] As shown in the accompanying drawings, a starch paste machine for brewing beer includes a body 1 whose lower part is in the shape of a cone barrel and whose upper part is in the shape of a cylindrical barrel. Stirring teeth and a slurry pump 3 are provided, the upper end of the body 1 is provided with a first-stage mixing sleeve 4, the upper end of the first-stage mixing sleeve 4 is connected to the feed pipe 5, and the first-stage mixing sleeve 4 is connected to the slurry mixing water pipe 6 , the middle part of the body 1 is provided with an overflow pipe 7, the feed pipe 5 in the present invention is in a spiral shape, and the primary mixing sleeve 4 is connected with the feed pipe 5 in an involute form, so that the feed pipe 5 enters a The powder in the stage mixing sleeve 4 descends in a spiral shape under the action of gravity, and is fully mixed with the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com