Orthogonal transducer type cylindrical traveling-wave ultrasonic motor vibrator

An ultrasonic motor, cylindrical technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problem of reducing the mechanical output capacity and controllability of ultrasonic motors, Problems such as the limitation of the mechanical output capacity of the ultrasonic motor and the distortion of the vibration trajectory of the particle on the surface of the vibrator have achieved the effects of improving the mechanical output capability and controllability, avoiding the distortion of the vibration trajectory, and flexible design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

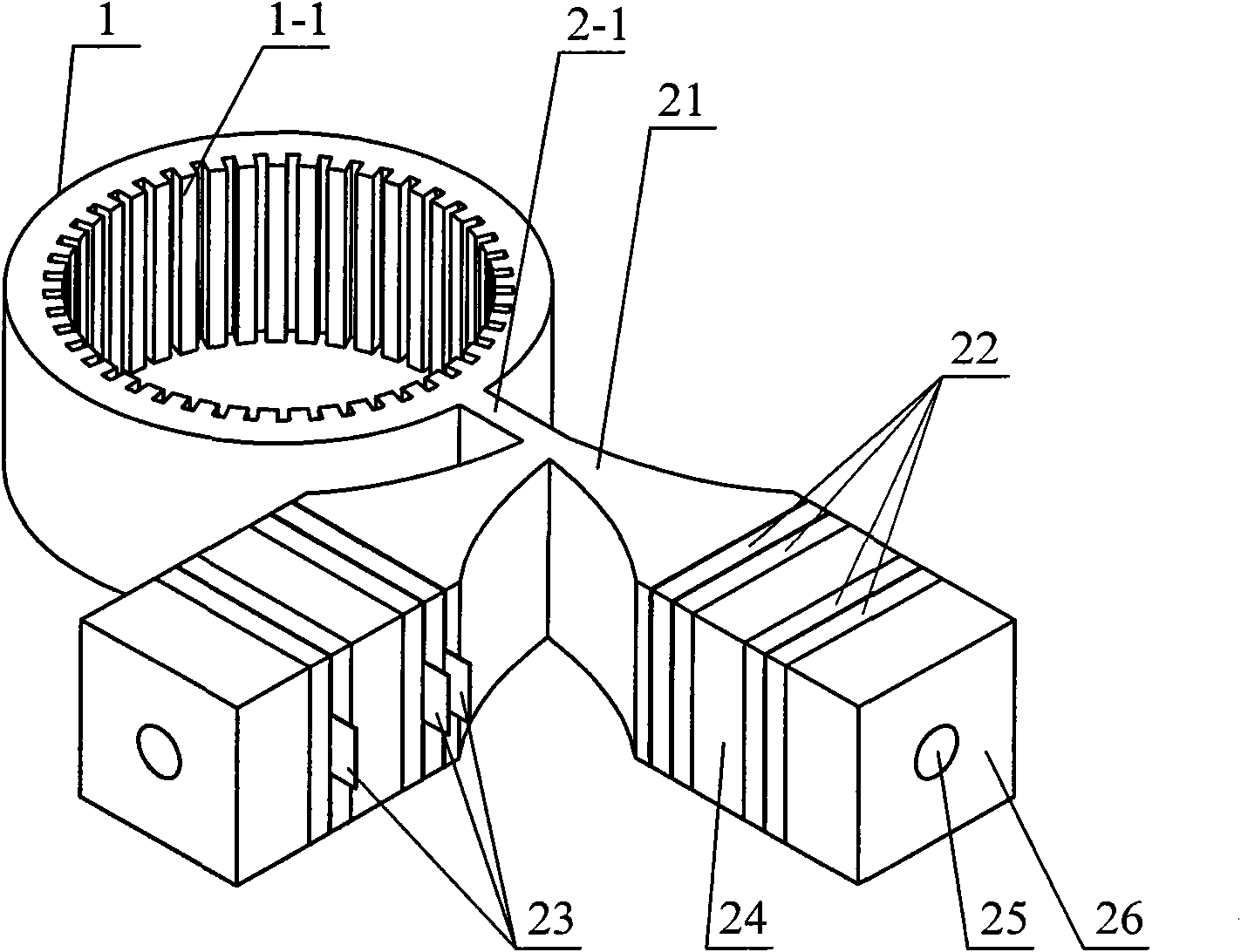

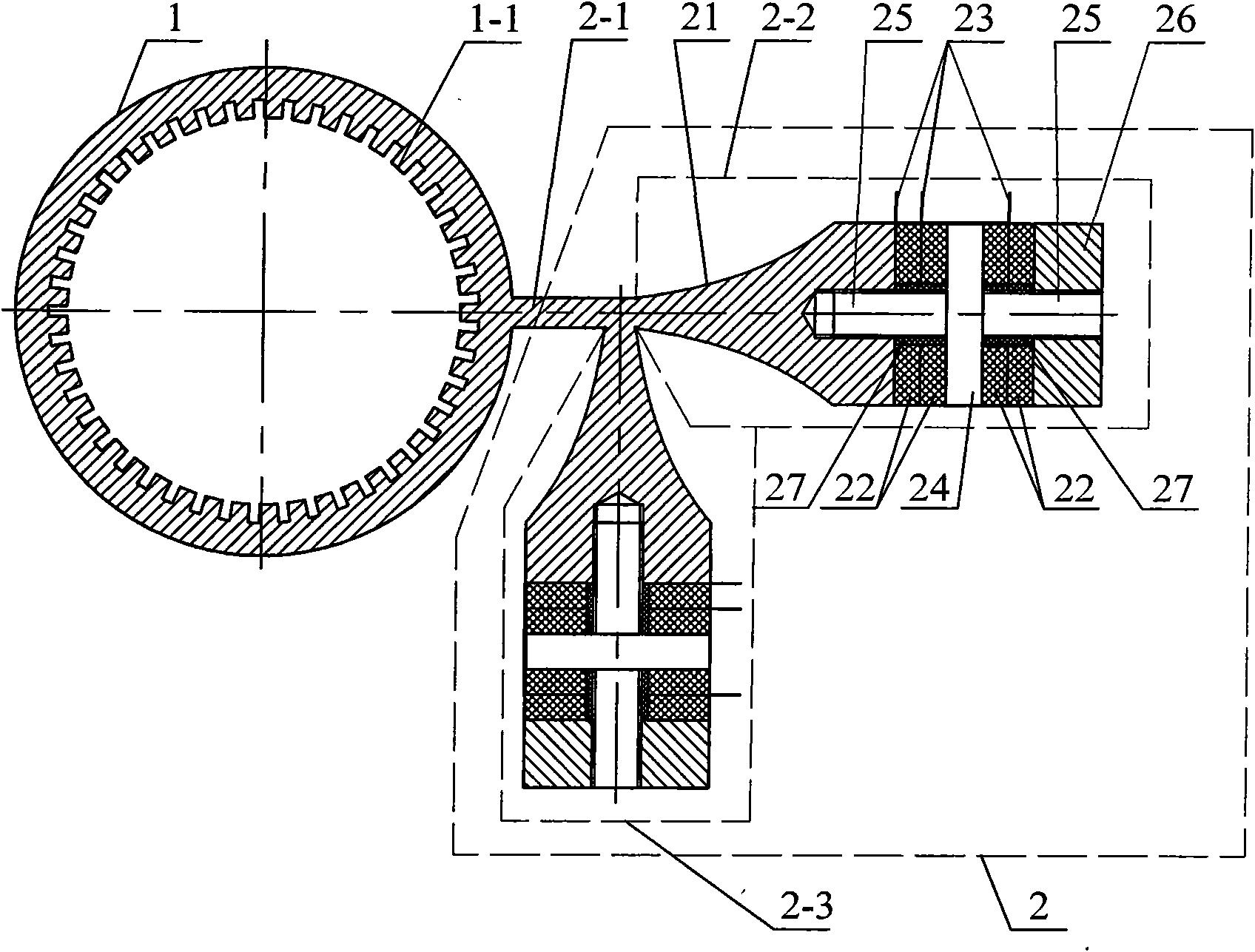

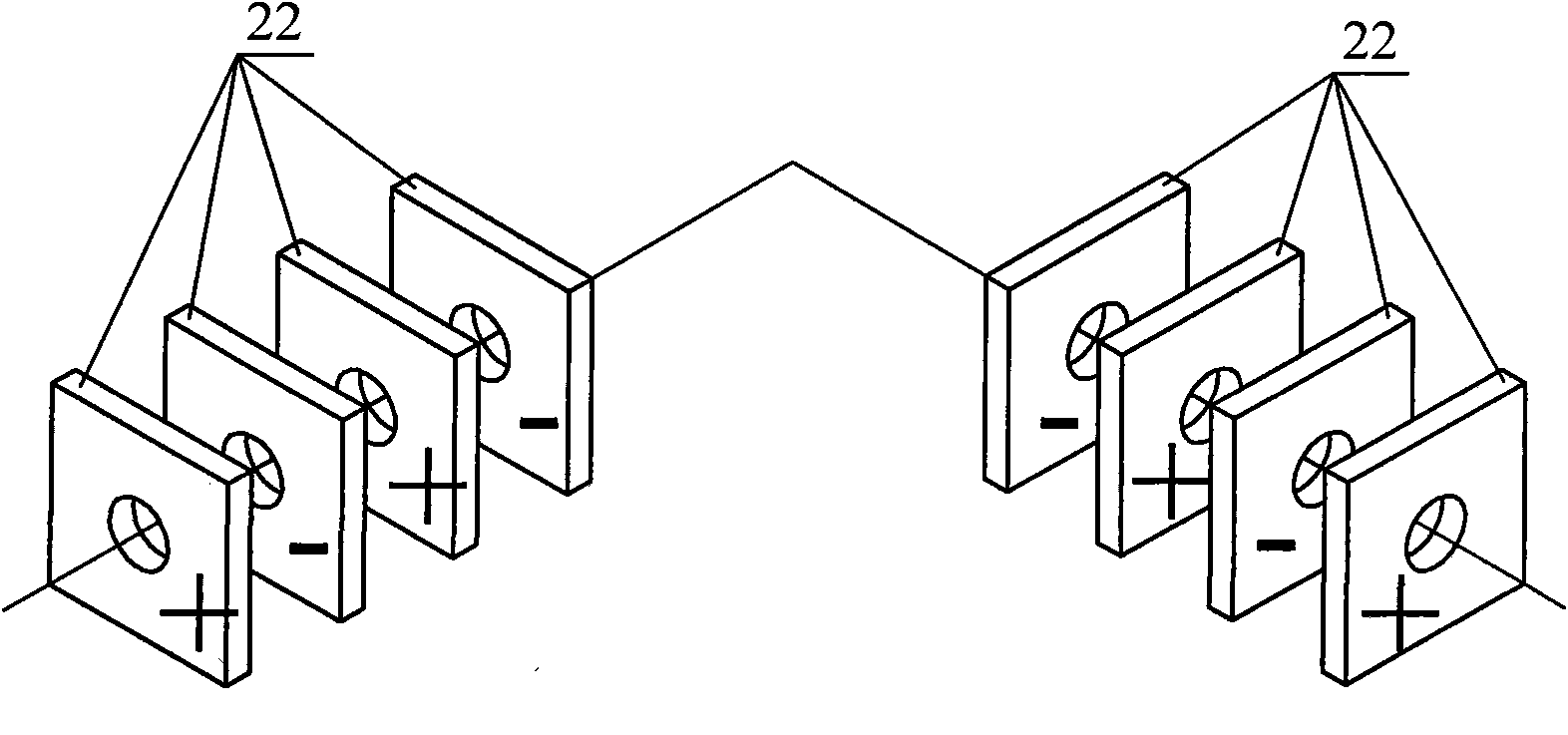

[0014] Specific implementation mode one: the following combination Figure 1 to Figure 6 Describe this embodiment, this embodiment comprises cylinder 1, and it also comprises positive transducer 2, and positive transducer 2 is made up of cantilever 2-1, first transducer 2-2 and second transducer 2-3 The first transducer 2-2 and the second transducer 2-3 are respectively composed of a horn 21, four piezoelectric ceramic sheets 22, three electrode sheets 23, a flange 24, two studs 25, The rear end cover 26 is composed of two insulating sleeves 27,

[0015] The horn 21 is a quadrangular prism whose cross-section is rectangular and tapered from one end to the other. The small end surfaces of the two horns 21 of the first transducer 2-2 and the second transducer 2-3 are Orthogonally integrated, the intersecting small end surfaces of the two horns 21 are integrated with one end surface of the cantilever 2-1, the other end surface of the cantilever 2-1 is integrated with the outer s...

specific Embodiment approach 2

[0021] Embodiment 2: This embodiment differs from Embodiment 1 in that the cross-sections of the piezoelectric ceramic sheet 22 and the flange 24 are rectangular. Other components and connections are the same as those in Embodiment 1.

specific Embodiment approach 3

[0022] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the cross-sections of the piezoelectric ceramic sheet 22 and the flange 24 are circular. Other components and connections are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com