Ceramics catalyst surface active coating and its preparation method

A technology of ceramic catalyst and surface activity, which is applied in the direction of catalyst activation/preparation, catalyst carrier, chemical instruments and methods, etc., which can solve the problems of low coating amount of active coating, high equipment requirements, complicated operation, etc., and achieve easy quantification The effect of chemical and industrialized production, low shedding rate and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

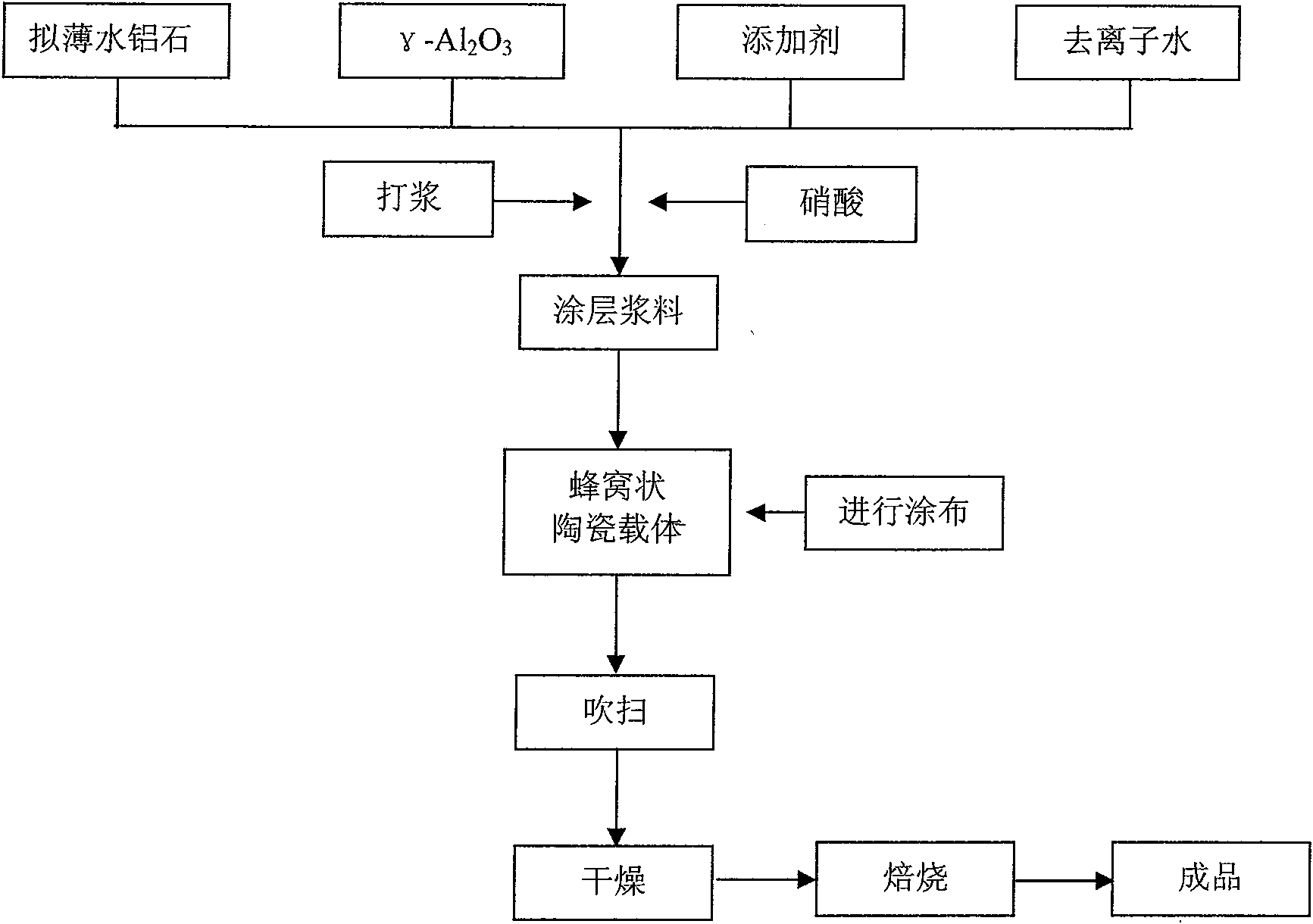

Method used

Image

Examples

Embodiment 1

[0028] Weigh 5g of pseudo-boehmite, 10g of deionized water, 0.05g of ethylene glycol, mix well, beat at 600r / min for 15min, add HNO 3 Adjust the pH of the slurry to 3.5.

[0029] The honeycomb ceramics were immersed in the coating slurry for 1 min, and the excess slurry in the channels was blown away with high-pressure air, then dried at 120°C for 4 hours, and fired at 500°C for 3 hours to obtain a coating. The active coating loading was 14.75%.

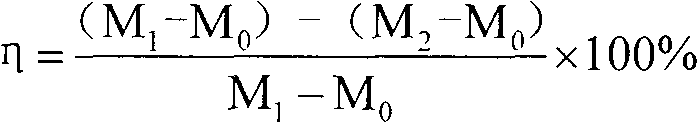

[0030] After the same detection steps as the comparative example, the shedding rate of the coating obtained in this embodiment was 1.53%.

Embodiment 2

[0032] Weigh 5g of pseudo-boehmite, 10g of deionized water, and 0.05g of glycerol, mix well, beat at a speed of 600r / min for 15min, add HNO 3 Adjust the pH of the slurry to 3.5.

[0033] The honeycomb ceramics were dipped in the coating slurry for 1 min, and after taking it out, the excess slurry in the channels was blown away with high-pressure air, then dried at 120°C for 4 hours, and fired at 500°C for 3 hours to obtain a coating. The active coating loading was 14.58%.

[0034] After the same detection steps as the comparative example, the shedding rate of the coating obtained in this embodiment was 0.19%.

Embodiment 3

[0036] Weigh 5g of pseudo-boehmite, 10g of deionized water, 0.05g of polyethylene glycol 300, mix well, beat at 600r / min for 15min, add HNO 3 Adjust the pH of the slurry to 3.5.

[0037] The honeycomb ceramics were dipped in the coating slurry for 1 min, and after taking it out, the excess slurry in the channels was blown away with high-pressure air, then dried at 120°C for 4 hours, and fired at 500°C for 3 hours to obtain a coating. The active coating loading was 14.51%.

[0038] After the same detection steps as the comparative example, the shedding rate of the coating obtained in this embodiment was 0.99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com