Method for preparing 4A zeolite by continuous crystallization

A technology of crystallization and zeolite, applied in the fields of washing and chemical industry, can solve problems such as difficult cleaning of pipeline scars, single temperature of crystallization temperature, long residence time of materials, etc., to reduce manual control points, stabilize product quality, and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

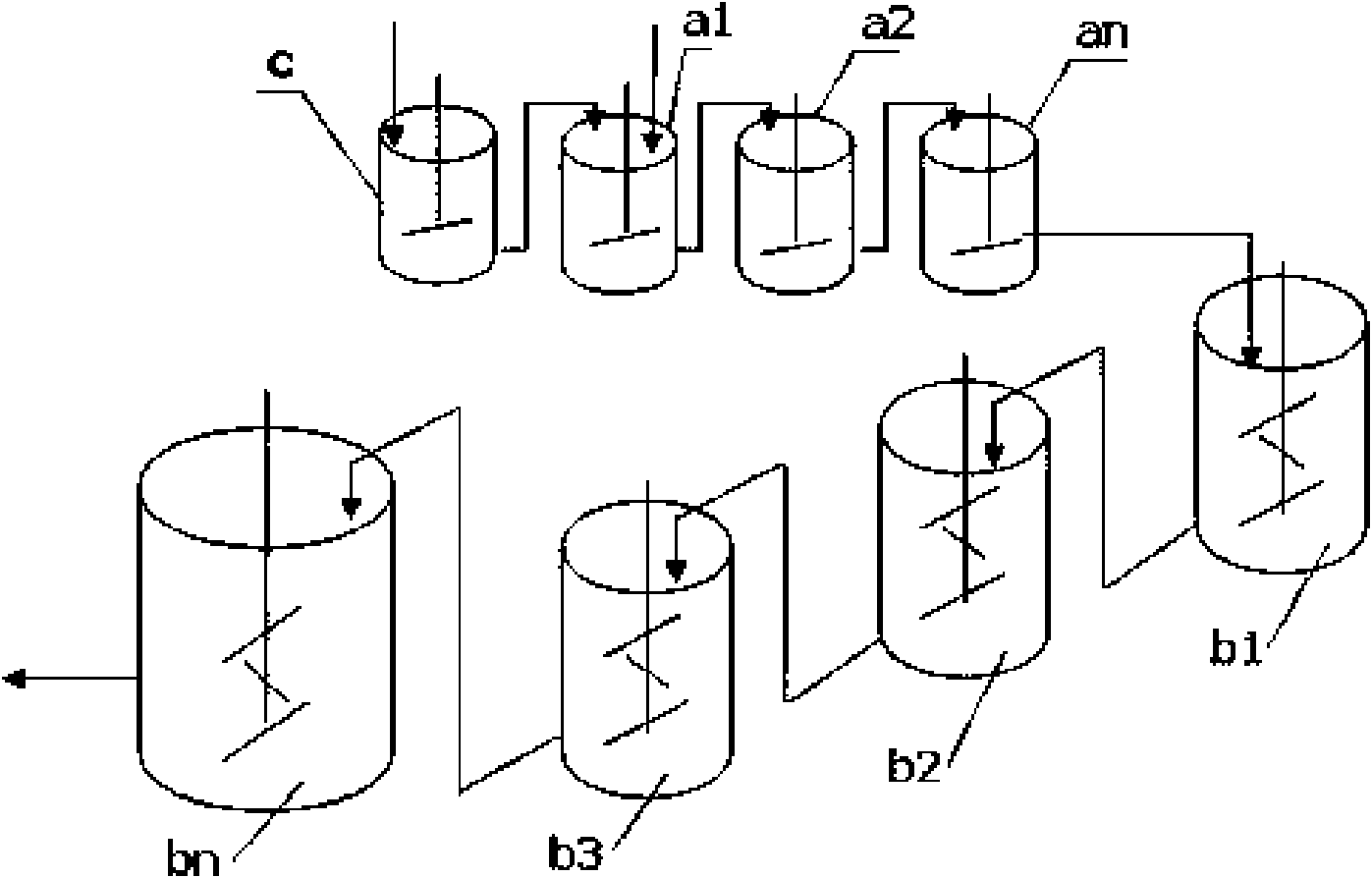

[0022] Slurry process: Al 2 o 3 Sodium metaaluminate solution with a concentration of 40g / l and SiO 2 The water glass solution with a meter concentration of 8% is simultaneously added to the stirring reaction tank c according to the silicon-aluminum molar ratio of 1, so that the sodium metaaluminate solution and the water glass are fully mixed and homogenized, and the reaction temperature is controlled at 30 ° C. pulp;

[0023] Pre-crystallization process: The slurry in the above steps is continuously pumped into the first pre-crystallization tank a1 in series with a delivery pump body, and 4A zeolite directing agent is added, wherein the volume ratio of 4A zeolite directing agent to slurry is 3‰. The pump body continuously sends the above slurry into the second pre-crystallization tank a2, the third pre-crystallization tank a3, and the eighth pre-crystallization tank a8 (n is 8); the slurry is pre-crystallized in the pre-crystallization tank And trigger the crystal nucleus...

Embodiment 2

[0027] Slurry process: Al 2 o 3 Sodium metaaluminate solution with a concentration of 80g / l and SiO 2 The water glass solution with a meter concentration of 13% is simultaneously added into the stirring reaction tank c according to the silicon-aluminum molar ratio of 1.5, so that the sodium metaaluminate solution and the water glass are fully mixed and homogenized, and the reaction temperature is controlled at 50 ° C. pulp;

[0028] Pre-crystallization process: Continuously pump the slurry in the above steps into the first pre-crystallization tank a1 in series with a delivery pump body, add 4A zeolite guiding agent, wherein the volume ratio of 4A zeolite guiding agent to slurry is 4‰, and use the delivery pump The pump body continuously sends the above slurry into the second pre-crystallization tank a2, the third pre-crystallization tank a3, and the fourth pre-crystallization tank a4 (n is 4); the slurry is pre-crystallized in the pre-crystallization tank And trigger the cr...

Embodiment 3

[0032] Slurry process: Al 2 o 3 Sodium metaaluminate solution with a concentration of 100g / l and SiO 2 The water glass solution with a meter concentration of 19% is simultaneously added into the stirring reaction tank c according to the silicon-aluminum molar ratio of 2, so that the sodium metaaluminate solution and the water glass are fully mixed and homogenized, and the reaction temperature is controlled at 70 ° C to obtain the pulp;

[0033] Pre-crystallization process: Continuously pump the slurry in the above steps into the first pre-crystallization tank a1 in series with the delivery pump body, add 4A zeolite directing agent, wherein the volume ratio of 4A zeolite directing agent to slurry is 6‰, and use the conveying pump The pump body continuously sends the above slurry into the second precrystallization tank a2 (n is 2); the slurry is precrystallized in the precrystallization tank and induces crystal nuclei to make the 4A crystal grow initially, and controls all precr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com