New method for preparing molybdenum phosphide by reducing molybdenum trioxide precursor

A technology of molybdenum trioxide and molybdenum phosphide, which is applied in the fields of chemical instruments and methods, catalyst activation/preparation, phosphide, etc., can solve the problems of high preparation temperature and difficult realization of programmed temperature reduction, and achieve low preparation temperature and equipment Effect of low cost, good HDS and HDN activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

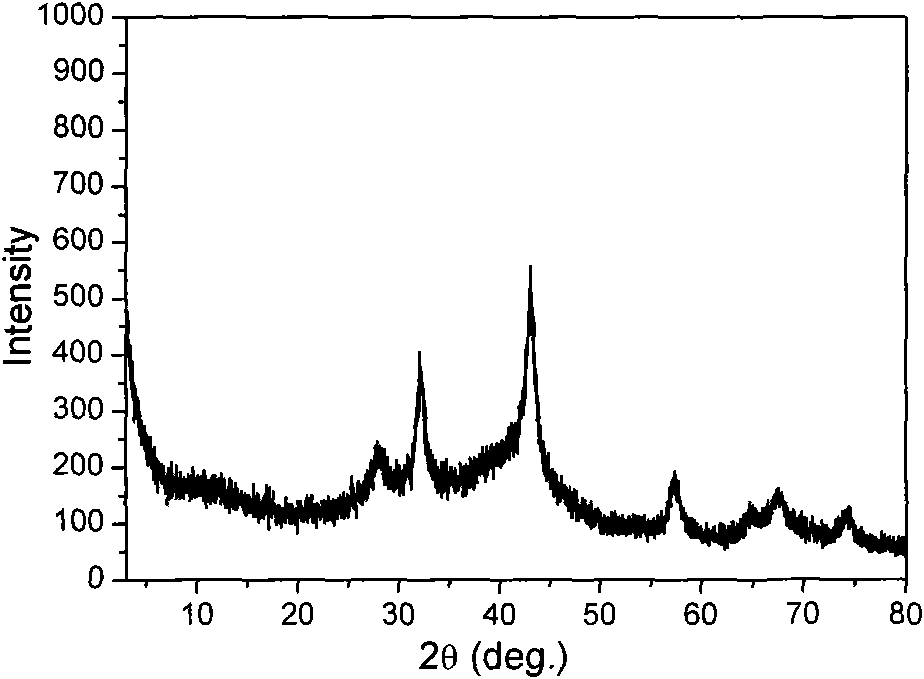

[0015] First, 16.06 g of sodium hypophosphite (NaH 2 PO 2 .H 2 O) was added to 50mL deionized water, and after dissolving for 10min, 4.34g of MoO was added 3 . After continuing to stir for 2 hours, the resulting solution was put into a petri dish and dried at 100°C. Then put the dried precursor powder into the reactor, heat treatment at 300°C for 10 minutes under the protection of static nitrogen, and then wash the product with water and then dry it. The obtained sample is named A, and A has attached figure 1 Characteristics.

Embodiment 2

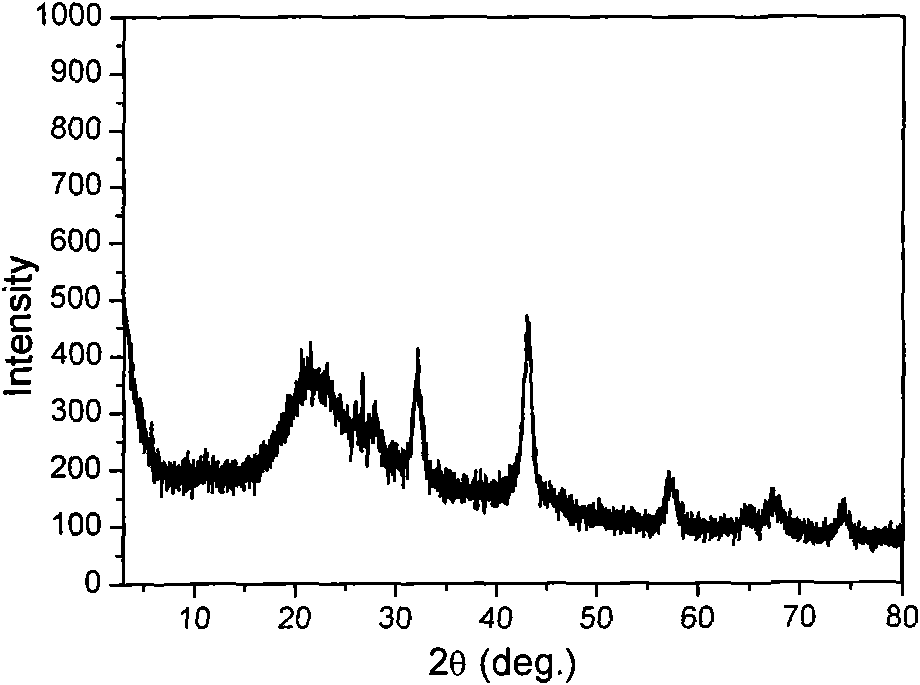

[0017] First, 2.50 g of ammonium molybdate ((NH 4 ) 6 Mo 7 o 24 .4H 2 O) was added to 27mL deionized water, and after dissolving for 10min, 4.48g of MCM-41 molecular sieves were added. After continuing to stir for 2 hours, the resulting solution was put into a petri dish and dried at 100°C. Then put the dried precursor powder into a muffle furnace, and bake it in an air atmosphere at 550°C for 2 hours to obtain a supported molybdenum trioxide (MoO 3 / MCM-41). With stirring at room temperature, 7.50 g of NaH 2 PO 2 .H 2 O was added to 27mL deionized water, and after dissolving for 10min, the supported molybdenum trioxide (MoO 3 / MCM-41). After continuing to stir for 2 hours, the resulting solution was put into a petri dish and dried at 100°C. Then put the dried precursor powder into the reactor, heat treatment at 300°C for 10min under the protection of static nitrogen, and then wash the product with water and then dry it. The obtained sample is named B, and B has att...

Embodiment 3

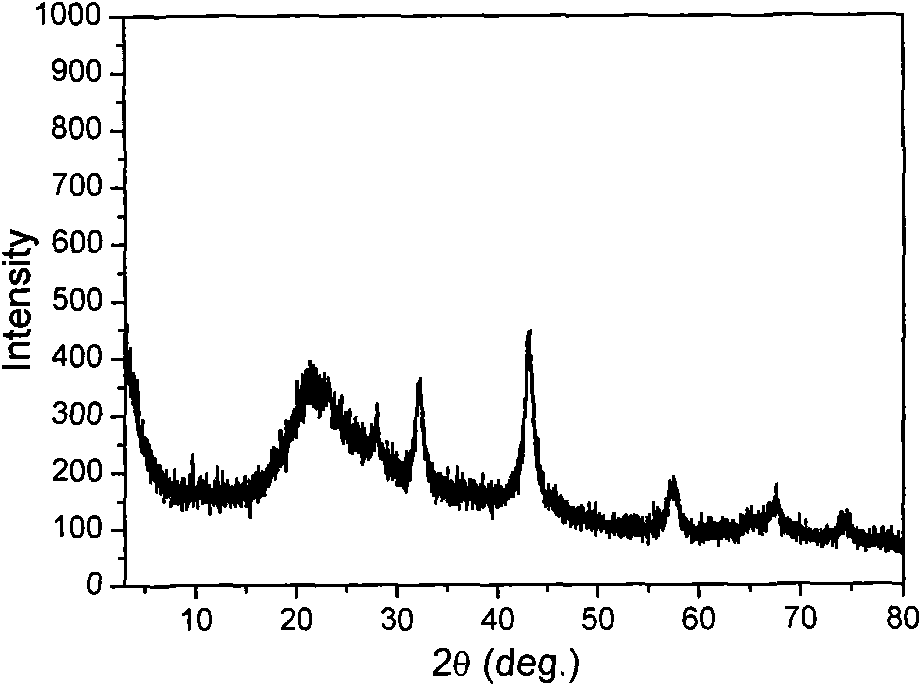

[0019] The preparation process is the same as that of sample B, only changing the NaH 2 PO 2 .H 2 The amount of O is 9.00 g, and other conditions remain unchanged. The obtained sample was named C, and C has attached image 3 Characteristics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com