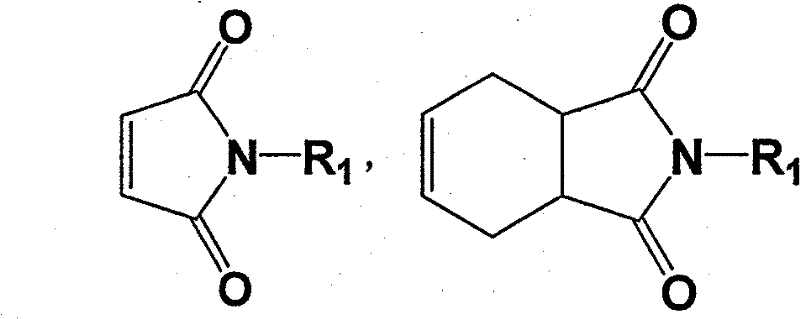

Organic-inorganic composite optothermal stabilizer, polyvinyl chloride prepared by using same and preparation method thereof

A photothermal stabilizer and inorganic composite technology, applied in the field of polymers, can solve the problems of compatibility of volatile organic substrates, low photostabilization efficiency, poor thermal stability, etc., and achieve enhanced photoprotection efficiency and long-term stability. The effect of improving, improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The natural hydrotalcite (LDH) was calcined at about 300°C for about 8 hours. Weigh 5 phr of the calcined product and 5 phr of 2-hydroxy-4-methoxy-5-sulfonic acid benzophenone (BP-4) into 20 phr of water. Stir well, react at about 80°C for about 40 hours, filter, wash and dry the product to obtain an organic-inorganic composite, and fully mix the composite with 0.2% titanate coupling agent by weight of the composite. Suspend the coupled organic-inorganic composite and 0.5% free radical scavenger by weight of the composite in water, apply ultrasonic irradiation for about 10 minutes, the frequency of ultrasonic is 20kHz, according to the material 200kW / m 3After irradiating and ultrasonic treatment, the product is filtered, washed and dried to obtain the desired organic-inorganic composite photothermal stabilizer. Recorded as organic-inorganic composite photothermal stabilizer I.

Embodiment 2

[0033] The artificial hydrotalcite (LDH) is calcined at about 600°C for about 3 hours. Weigh 5phr of the calcined product and 10phr of 2-hydroxy-4-methoxy-5-sulfonic acid benzophenone (BP-4) into 25phr of water. Stir well, react at about 100°C for about 10 hours, filter, wash and dry the product to obtain an organic-inorganic compound. The compound was thoroughly mixed with 3% titanate coupling agent and silane coupling agent (mass ratio 1:1). Suspend the coupled organic-inorganic compound and 5% free radical scavenger in ethanol, apply ultrasonic irradiation for about 20 minutes, the frequency of ultrasonic is 20kHz, according to the material 100kW / m 3 After irradiating and ultrasonic treatment, the product is filtered, washed and dried to obtain the desired organic-inorganic composite photothermal stabilizer. Recorded as organic-inorganic composite photothermal stabilizer II.

Embodiment 3

[0035] The natural hydrotalcite (LDH) is calcined at about 800°C for about 3 hours. Weigh 10phr of the calcined product and 2phr of 2-hydroxy-4-methoxy-5-sulfonic acid benzophenone (BP-4) into 25phr of water. Stir well, react at about 50°C for about 50 hours, filter, wash and dry the product to obtain an organic-inorganic compound. Mix this compound well with 5% silane coupling agent. Suspend the coupled organic-inorganic compound and 10% free radical scavenger in water, apply ultrasonic irradiation for about 30 minutes, the frequency of ultrasonic is 20kHz, according to the material 50kW / m 3 After irradiation and ultrasonic treatment, the product is filtered, washed and dried to obtain the desired organic-inorganic composite photothermal stabilizer. Recorded as organic-inorganic composite photothermal stabilizer III.

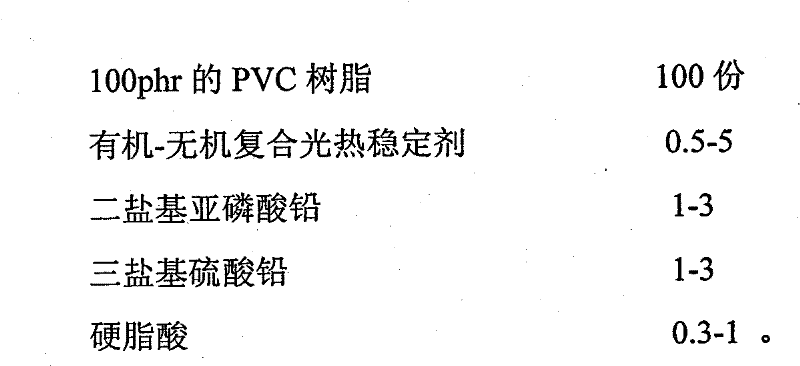

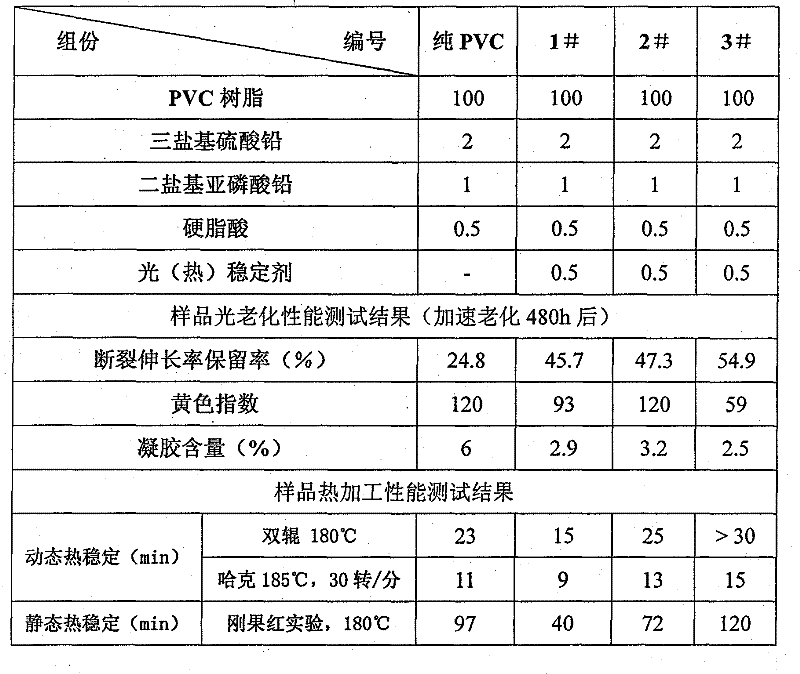

[0036] The examples and test results of the polyvinyl chloride containing the photothermal stabilizer provided by the present invention are given below.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com