Method for using amphipathy hyperbranched polymer to prepare quantum dots

An amphiphilic hyperbranched, polymer technology, applied in chemical instruments and methods, luminescent materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Step 1: Add 100 mg of hexadecyl chloride-terminated hyperbranched polyamidoamine into a 100 ml reaction bottle, and add 40 ml of chloroform to dissolve it to prepare an amphiphilic single-molecule nanomicelle solution.

[0026] Step 2: Add 5 ml of amphiphilic unimolecular nanomicelle solution containing 0.3×10 -5 molar Cd(AC) 2 The aqueous solution was sealed and stirred at room temperature for 48 hours, then left to stand, and the chloroform solution in the lower layer was separated into an isolation bottle.

[0027] The third step is to pass nitrogen gas into the isolation bottle for 15 minutes, and then add 2 ml containing 0.3×10 -5 Mole Na 2 S deoxygenated aqueous solution, continue to pass nitrogen for 10 minutes, and stir at room temperature for about 1 hour. A clear chloroform solution of CdS quantum dots can be obtained after static separation.

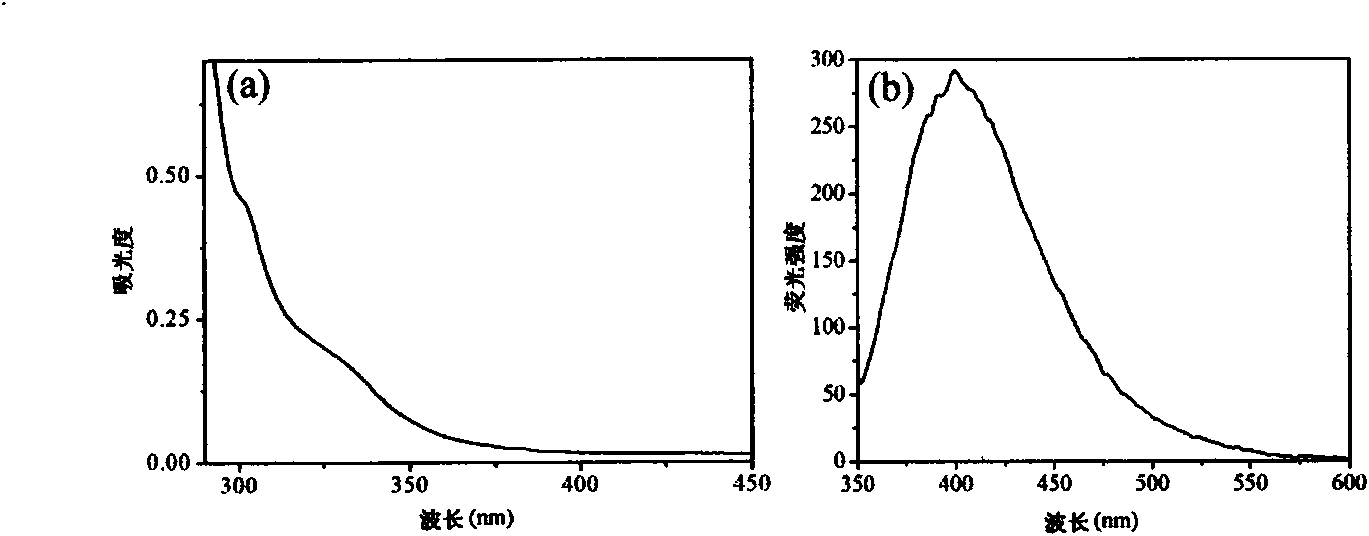

[0028] like figure 1 As shown in (a), the UV-visible spectrum of the CdS quantum dot prepared in the present emb...

Embodiment 2

[0030] Step 1: Add 100 mg of hexadecyl chloride-terminated hyperbranched polyethyleneimine to a 100 ml reaction bottle to prepare an amphiphilic unimolecular nanomicelle solution.

[0031] Step 2: Add 5 ml of amphiphilic unimolecular nanomicelle solution containing 1×10 -5 molar Cd(AC) 2 The aqueous solution was sealed and stirred at room temperature for 48 hours, then left to stand, and the chloroform solution in the lower layer was separated into an isolation bottle.

[0032] The third step is to pass nitrogen gas into the isolation bottle for 15 minutes, then add 2 ml and add 2 ml containing 1×10 -5 Mole Na 2 S deoxygenated aqueous solution, continue to pass nitrogen for 10 minutes, and stir at room temperature for about 1 hour. A clear chloroform solution of CdS quantum dots can be obtained after static separation.

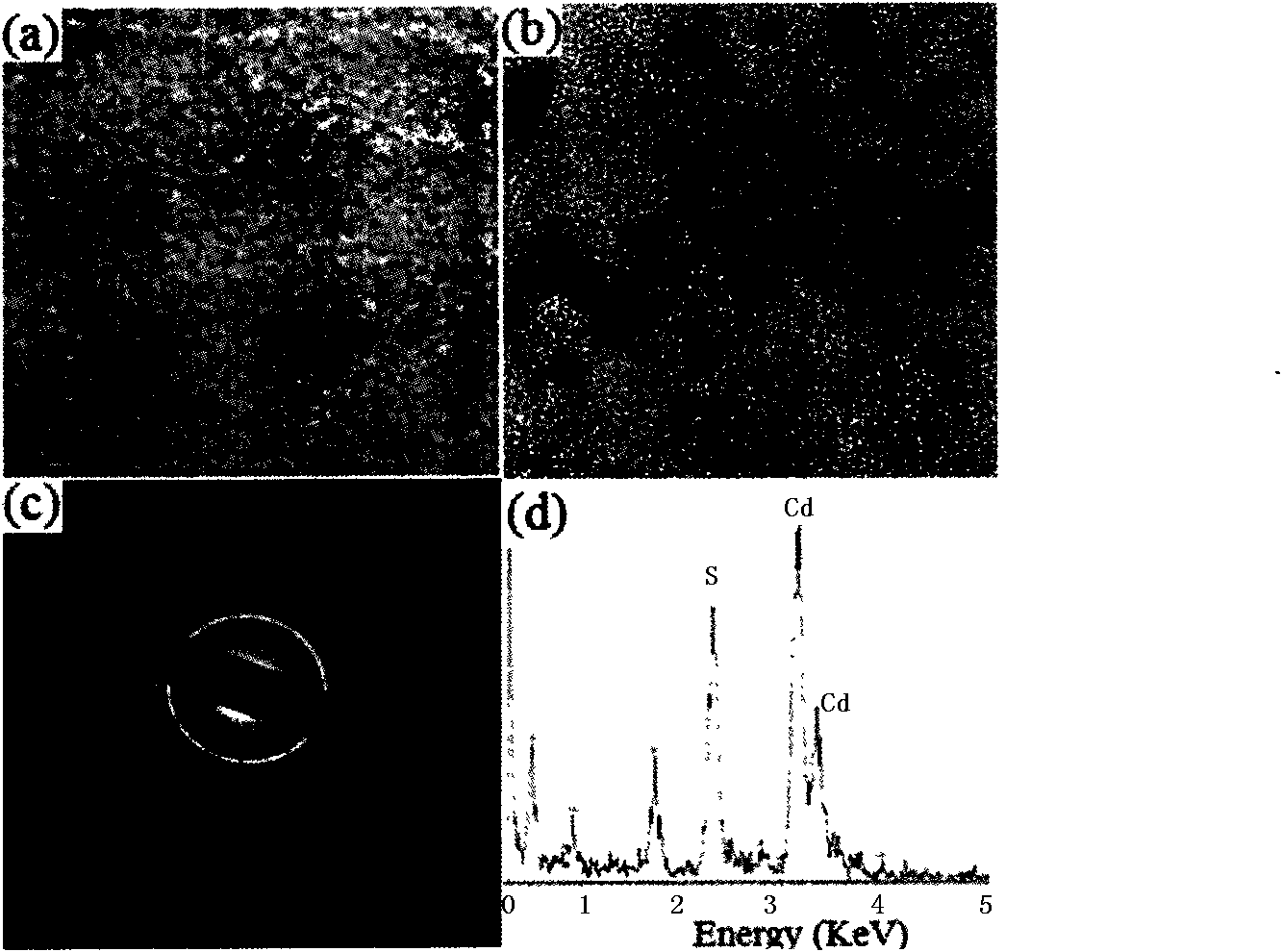

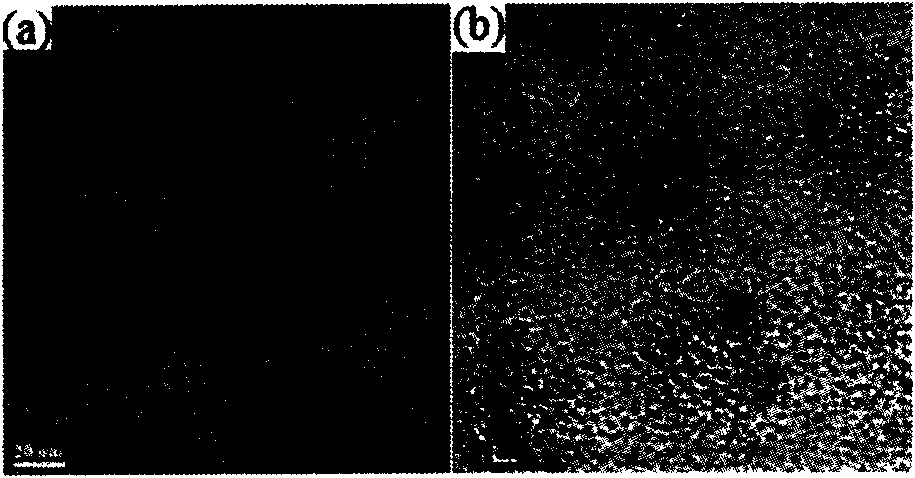

[0033] The transmission electron microscope figure of the CdS quantum dot prepared in the present embodiment is as follows image 3 (a) shown. It can be...

Embodiment 3

[0035] Step 1: Add 100 mg of hexadecyl chloride-terminated hyperbranched polysulfone-amine into a 100 ml reaction bottle, and then add 40 ml of chloroform to dissolve it to prepare an amphiphilic single-molecule nanomicelle solution.

[0036] Step 2: Add 5 ml of amphiphilic unimolecular nanomicelle solution containing 6×10 -5 molar Cd(AC) 2 The aqueous solution was sealed and stirred at room temperature for 48 hours, then left to stand, and the chloroform solution in the lower layer was separated into an isolation bottle.

[0037] The third step is to pass nitrogen gas into the isolation bottle for 15 minutes, and then add 2 ml containing 6×10 -5 Mole Na 2 S deoxygenated aqueous solution, continue to pass nitrogen for 10 minutes, and stir at room temperature for about 1 hour. The chloroform solution of CdS quantum dots can be obtained by static separation.

[0038] The transmission electron microscope figure of the CdS quantum dot prepared in the present embodiment is as f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com