Polyurethane elastic fiber finishing agent

A fiber treatment agent and polyurethane elastic technology, which is applied in fiber treatment, fiber type, textile and paper making, etc., can solve problems such as uneven distribution, aggravated reaction degree of isocyanate groups, unstable tension between polyurethane elastic fiber threads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

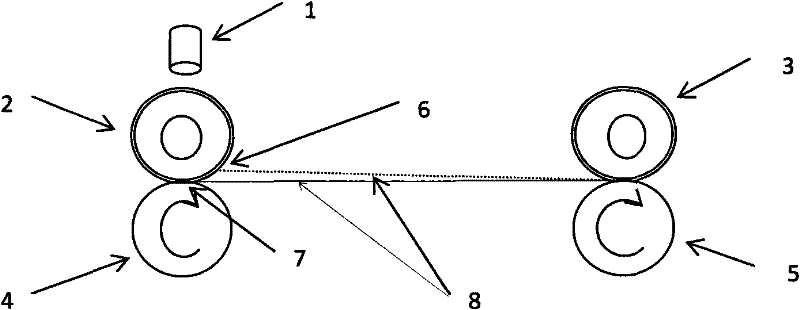

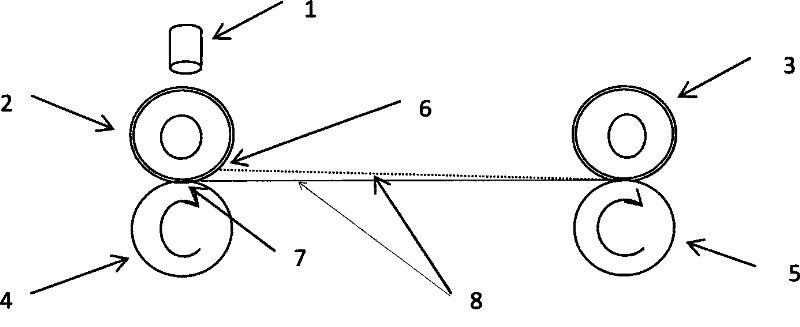

Image

Examples

Embodiment

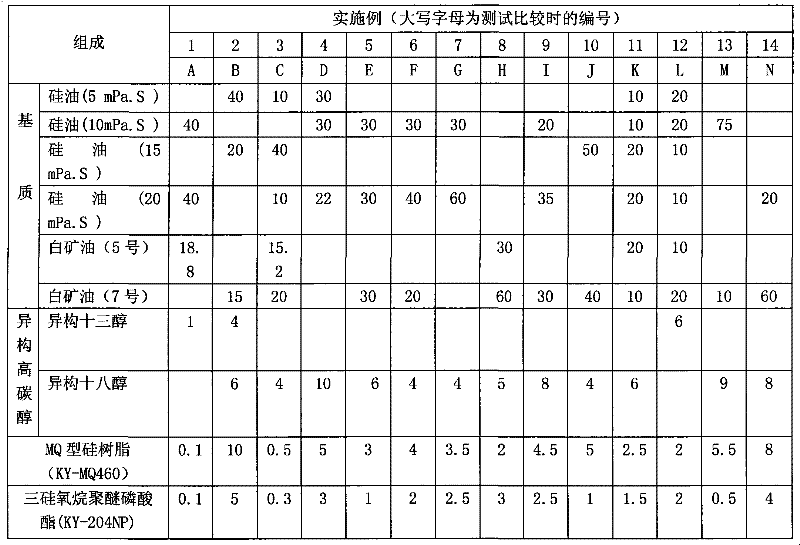

[0030] The technical scheme of the present invention is illustrated below according to different embodiments, these embodiments should not be interpreted as the restriction of the present invention, the equivalent technology that makes on the basis of the embodiments should all be regarded as protection scope of the present invention, select the composition of different weight parts Sub-production treatment agent of the present invention, its concrete data are shown in Table 1:

[0031] Table 1

[0032]

[0033] Note: KY-MQ460 is a methylphenyl MQ silicone resin with a pour point not greater than 100°C produced by Kaiyue Technology Development Co., Ltd.;

[0034] KY-204NP is trisiloxane polyether phosphate with monoester molar content not less than 50% produced by Kaiyue Technology Development Co., Ltd.

[0035] The test comparison of the antistatic, durable anti-sticking, rolling and unwinding performance of the above-mentioned embodiments and comparative examples is show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com