Funnel-shaped valve piezoelectric pump and working method thereof

A piezoelectric pump and funnel-shaped technology, applied in the field of passive valve piezoelectric pumps, can solve the problems of unfavorable piezoelectric pump miniaturization, reliability improvement, difficulty in processing and installation, unstable work, etc., and achieve small energy loss and disturbance Effect of small size and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

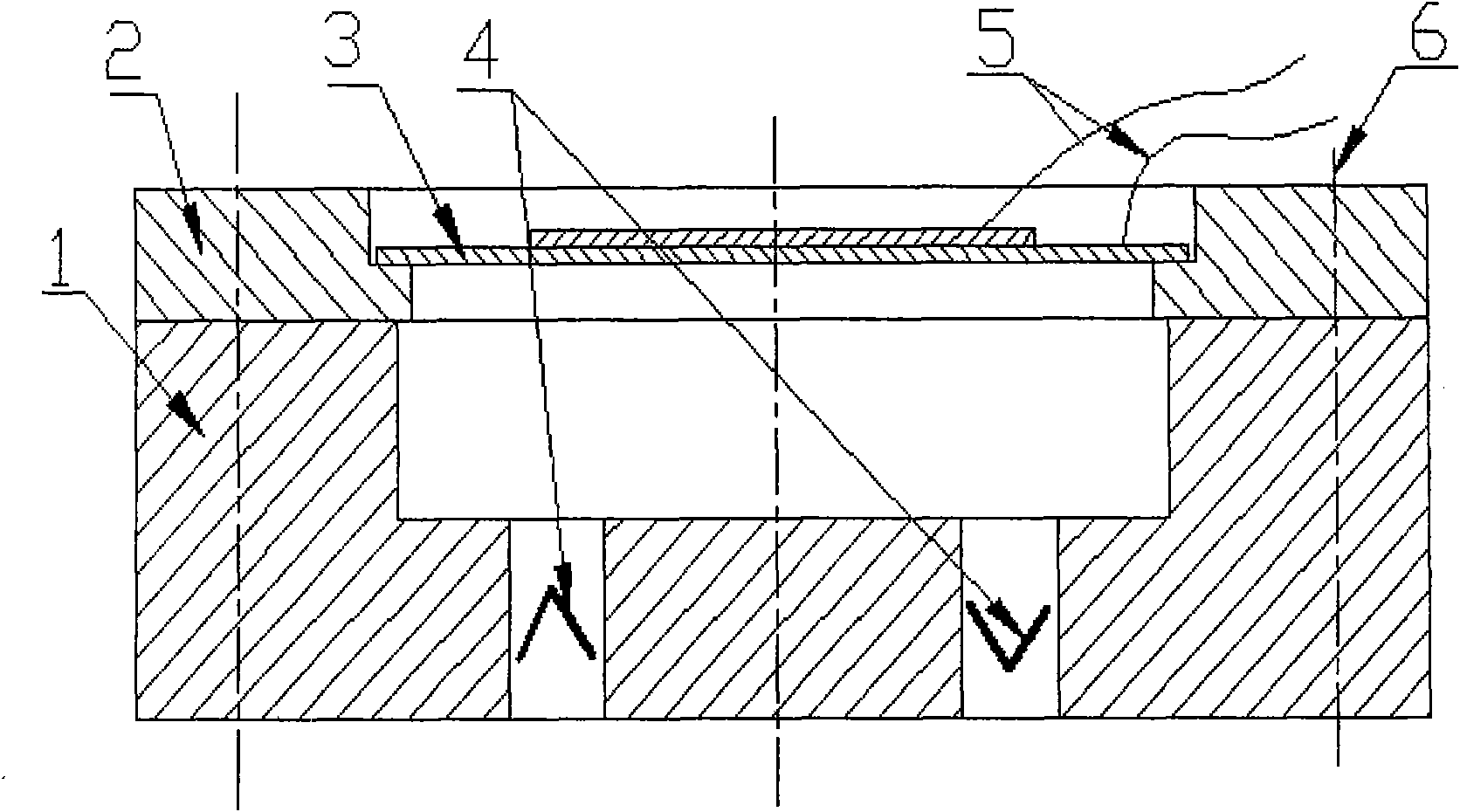

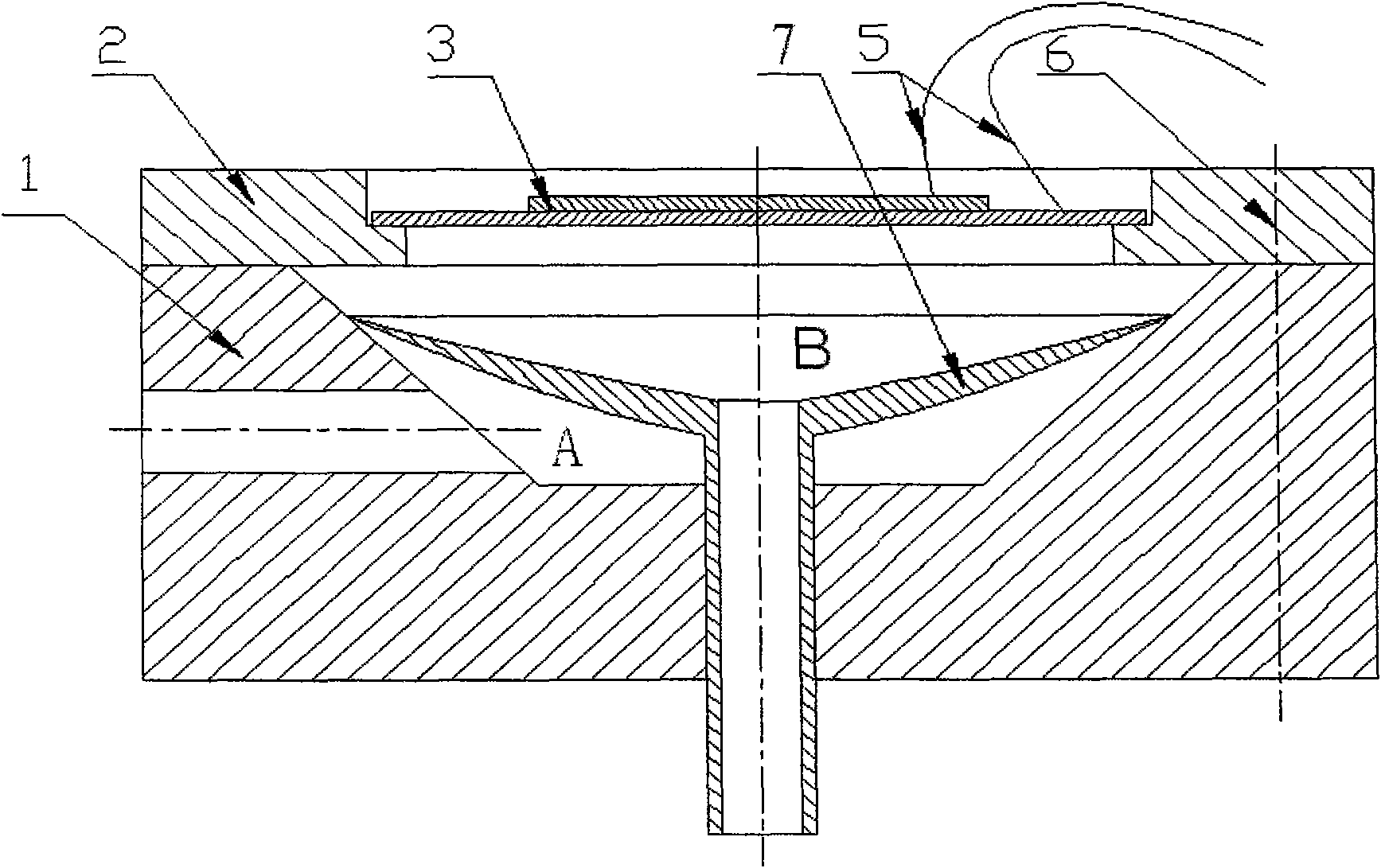

[0018] A new type of passive valve piezoelectric pump provided by the present invention-a funnel-shaped valve piezoelectric pump, the structure is as follows figure 2 As shown, the circumference of the circular piezoelectric vibrator 3 with wires is firmly supported on the stepped groove of the pump cover 2, the pump cover 2 and the pump body 1 are fastened together with 5 bolts (6 pieces), and the pump cavity of the pump body is funnel-shaped A through hole is opened on the side and bottom of the pump body. The side hole is the pump inlet. A funnel-shaped valve body 7 with a conduit is installed in the pump cavity. The angle of the funnel-shaped valve body is different from that of the funnel-shaped cavity. The chamber is divided into two chambers, A and B. The valve body is made of a material with good elasticity (such as: resin) into a funnel shape with a thick center and thin edges. A central hole is opened on it to connect with the conduit. The edge of the valve body is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com