Double-area multi-stage electrostatic precipitator of reverse airflow dust charge

An electrostatic precipitator, dust charging technology, applied in the direction of electrostatic separation, electrostatic effect separation, chemical instruments and methods, etc., can solve the problem of poor dust removal effect of high specific resistance dust, improve the charging effect and avoid charge accumulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

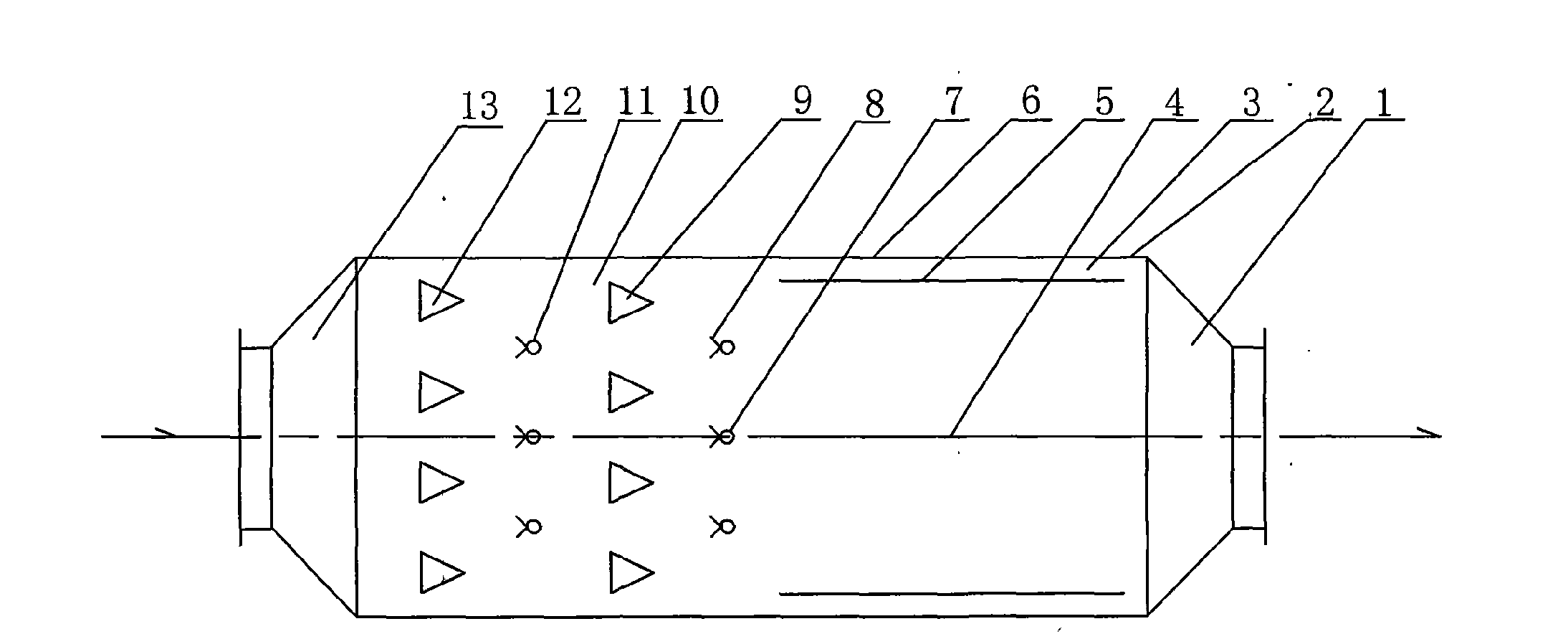

[0022] Such as figure 1 As shown, a dual-zone multi-stage electrostatic precipitator charged against airflow dust includes an air inlet box 13 and an air outlet box 1, and a section of dust removal section 6 is arranged between the air inlet box 13 and the air outlet box 1, and the dust removal section 6 includes The charging area 10 and the dust collection area 3, the dust collection area 3 is composed of plates and plate channels; the anode 12 of the charging area is composed of the anode grid row 9 formed by the vertical arrangement of grid grooves 15, so The negative electrode 11 of the above-mentioned charging area is composed of the cathode grid row 7 formed by the vertical arrangement of the grid tubes 14; On the downwind side of each grid tube 14 of the cathode grid row 7, an "eight"-shaped thorn 8 is provided on the windward side of each grid tube 14; the cross section of the grid groove 15 of the anode grid row 9 is an isosceles triangle The surface where the base o...

Embodiment 2

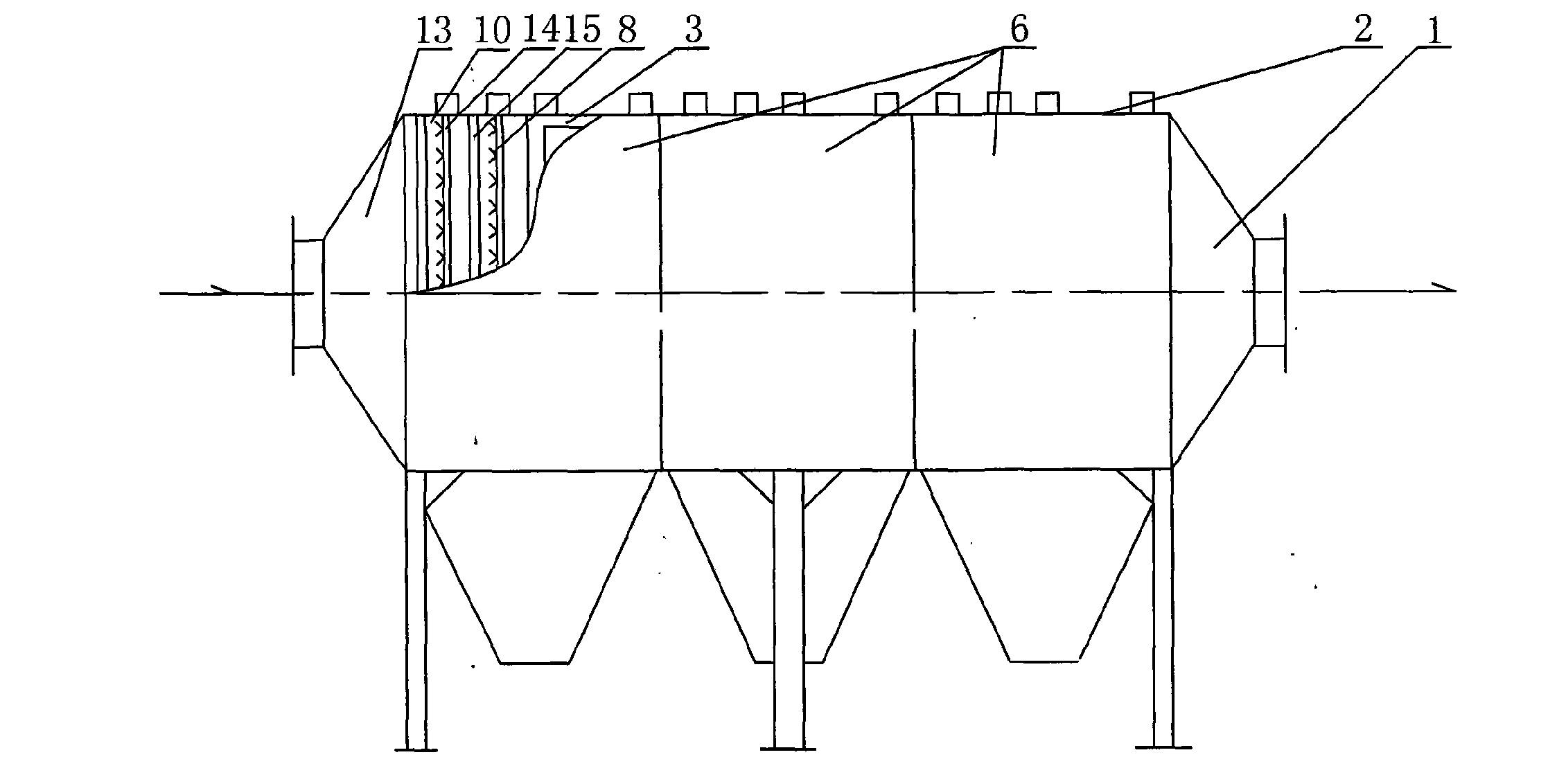

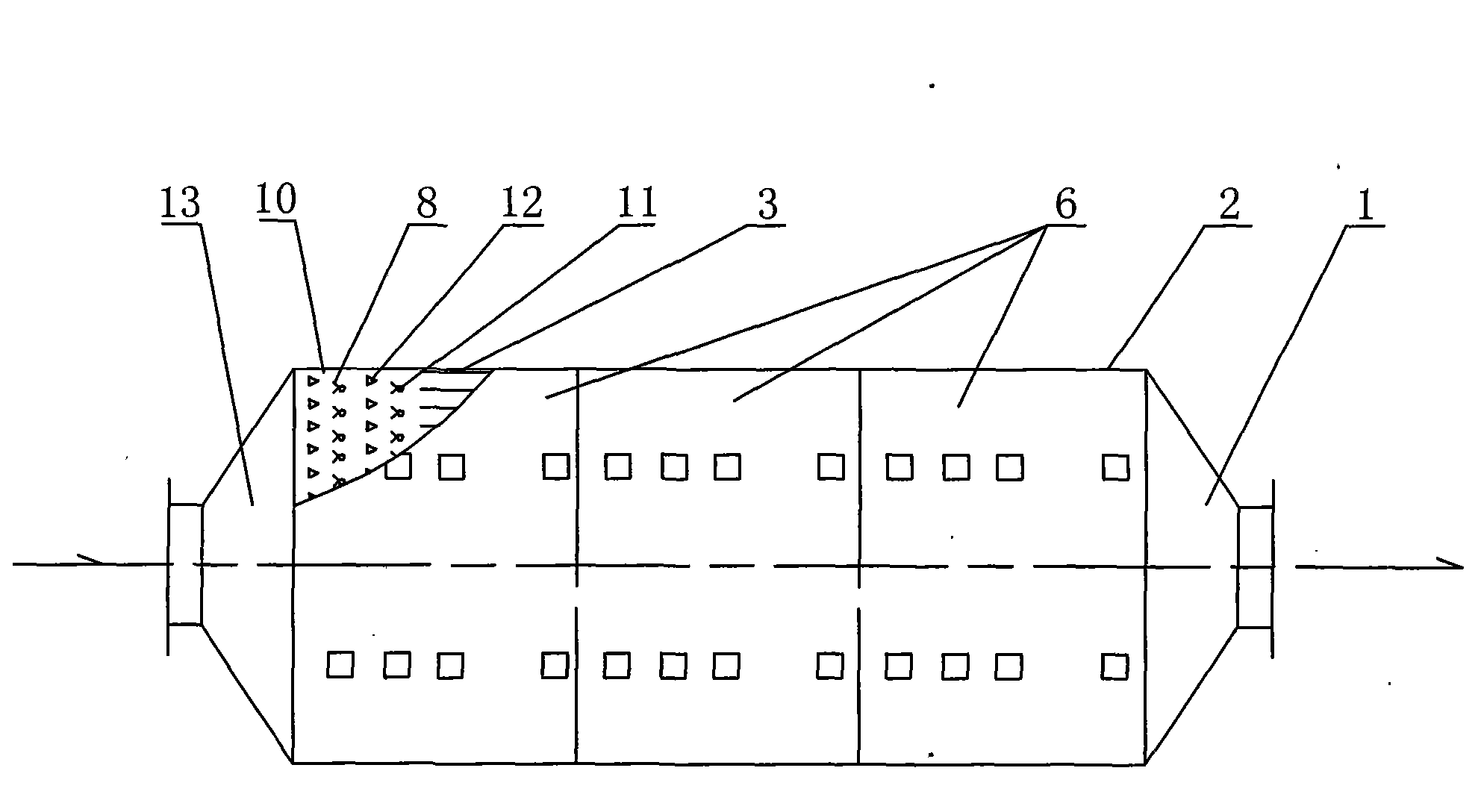

[0025] Such as figure 2 , image 3 As shown, a dual-zone multi-stage electrostatic precipitator charged against airflow dust is used to purify boiler flue gas in a coal-fired power plant. It includes an air intake box 13 and an air outlet box 1. There are three dust removal sections 6 arranged in between, and the three dust removal sections 6 are connected in series. Each dust removal section 6 includes a charging area 10 and a dust collection area 3. The dust collection area 3 is composed of plates and plate channels, and the dust collection area 3 It consists of 30 channels, and the anode dust collection plates on both sides of each channel are composed of 6 anode plates, the total length of the 6 anode plates is 3m, and the height of the anode plate is 6m; the cathode plate of each channel It consists of 12 cathode plates, and the cathode plates in every 10 channels form a group, which are connected together by a frame and supported by four porcelain bottles. The anode 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com