Method and device thereof for preparing metal semisolid size

A semi-solid slurry and metal technology, which is applied in the near-finished forming field of metal processing, can solve the problems of long process, strict temperature control requirements, and easy oxidation of molten metal, and achieve the effect of preventing oxidation and accurately controlling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

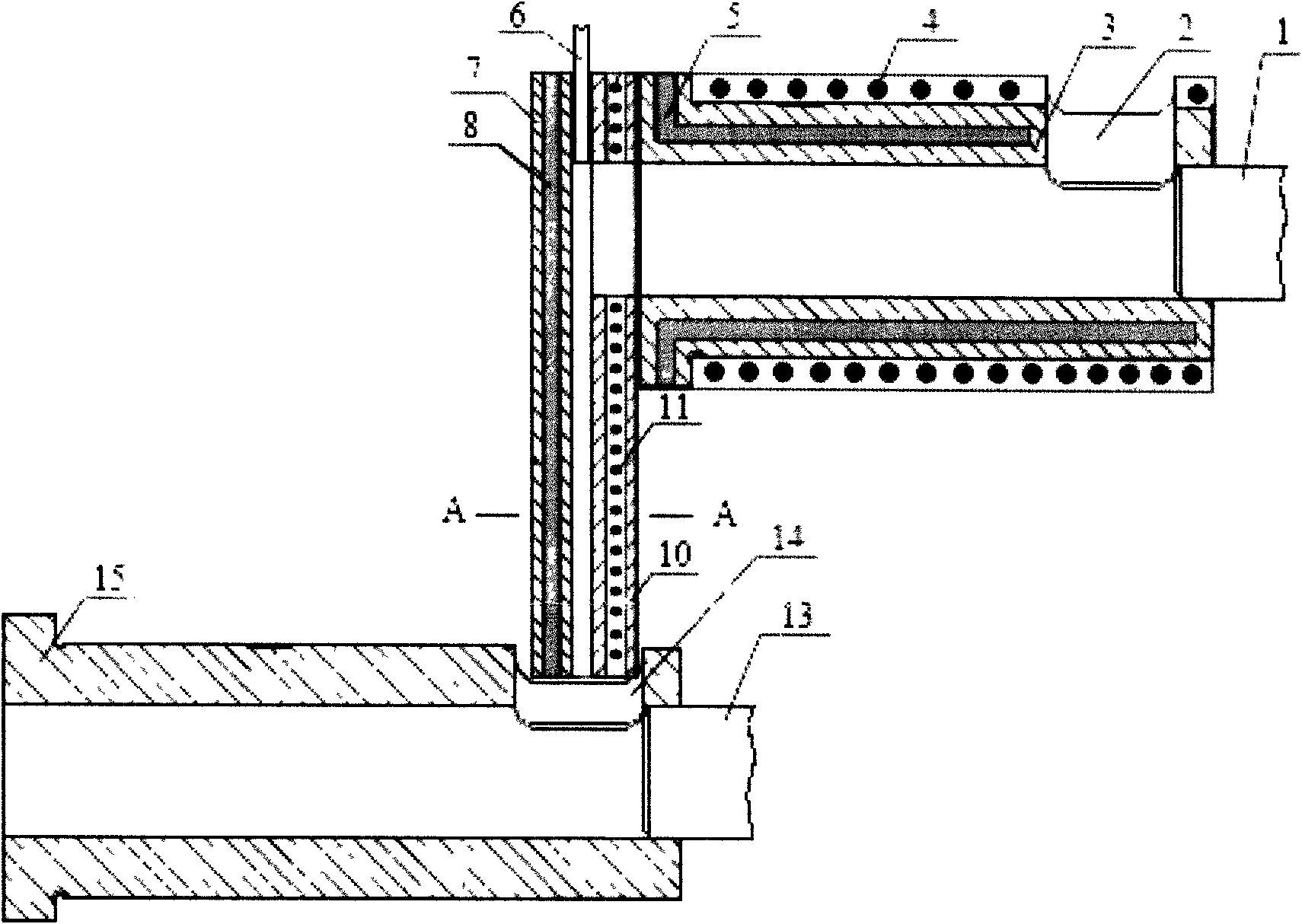

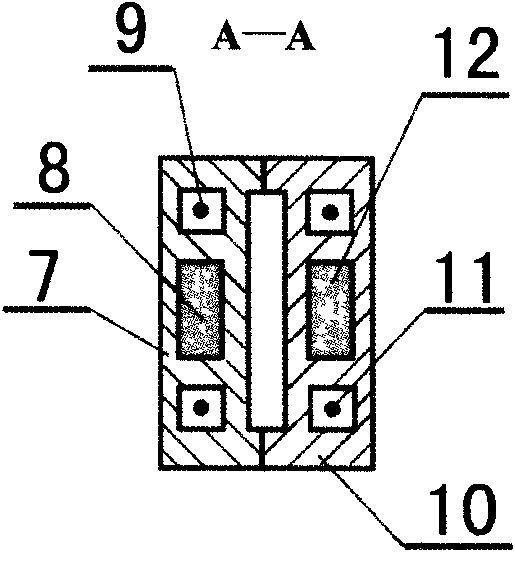

[0029] see figure 1 , 2 , The device of the present invention includes three parts: a channel system, a temperature control system and an auxiliary device. The channel system consists of a cylindrical punch 1, a flat punch 6, a left half-flat channel 7, and a right half-flat channel 10. The circular barrel 3 cooperates with the corresponding cylindrical punch 1 to form a plunger-type injection mechanism. , and the flat punch 6 cooperates with the left half-flat channel 7 and the right half-flat channel 10 to form another plunger-type injection mechanism. The temperature control system is composed of barrel heating element 4, left half-flat channel heating element 9 and right half-flat channel heating element 11, barrel cooling element 5, left half-flat channel cooling element 8 and right half-flat channel cooling element 12, these Both heating and cooling elements are provided in the outer walls of the circular cartridge and the flat channel, respectively. The auxiliary dev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com