Sandwich anti-fake element containing magnetic film, paper products containing the element and manufacturing method thereof

A technology of anti-counterfeiting components and production methods, which is applied in the direction of layered products, printed matter, computer parts, etc., can solve the problems of anti-counterfeiting component thickness and specific weight, unfavorable papermaking and anti-counterfeiting component hiding, etc., so as to improve anti-counterfeiting ability and concealment Anti-counterfeiting effect, beneficial effect of mosaic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

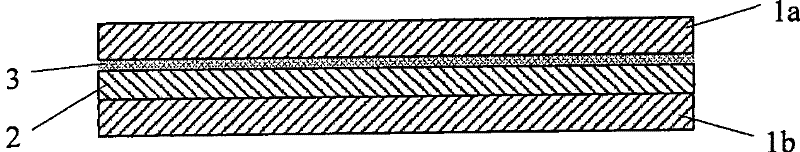

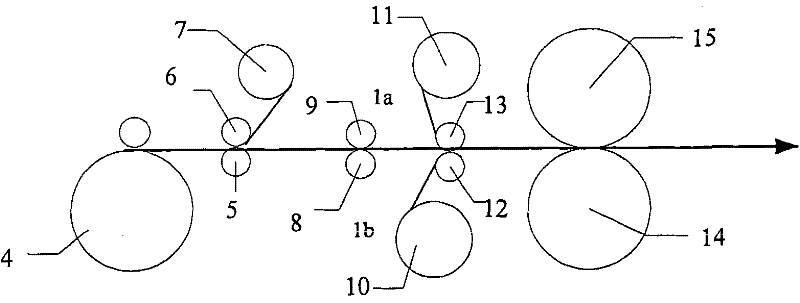

[0049] According to the ordinary copying process, the specific gravity of the copying is 0.65g / cm 3 , cotton fiber paper layer 1a and cotton fiber paper layer 1b with a thickness of 15 μm and 20 μm. On the PET substrate film with a thickness of 20 μm, a silicone oil release film 2 with a thickness of 10 μm is coated, and dried or cured. The raw material of the silicone oil release film is a commercially available product, and a fluoroplastic release film (commercially available) can also be used. A vacuum magnetron sputtering roll coater is used to sputter a layer of amorphous coating 3 with a thickness of 50 nm on the surface of the release film 2, such as the amorphous film in the embodiment of CN200710122026.3. On the peeling machine, the amorphous coating film 3 and the release film 2 are peeled off from the PET base film, and the starch adhesive is used for surface sizing, and then the cotton fiber paper layers 1a and 1b are laminated on the composite machine. put toget...

Embodiment 2

[0051] Choose a specific gravity of 0.85g / cm 3 The polypropylene film is used as masking layer 1a and 1b. On the PET substrate film with a thickness of 30 μm, a layer of fluoroplastic release film 2 with a thickness of 5 μm is coated and dried or cured. The raw material of the fluoroplastic release film is a commercially available product, and a silicone oil release film (commercially available) may also be used. Use a vacuum magnetron sputtering roll coater to sputter a layer of amorphous coating 3 with a thickness of 30nm on the surface of the release film 2, for example, the coating composition is Ni 38 Cr 8 Fe 54 alloy. On the peeling machine, the amorphous coating film 3 and the release film 2 are peeled off from the PET base film, and after surface sizing, they are pressed on the composite machine with the polypropylene films 1a and 1b as the masking layer by lamination. put together and get figure 1 For the anti-counterfeiting components shown, the specific proces...

Embodiment 3

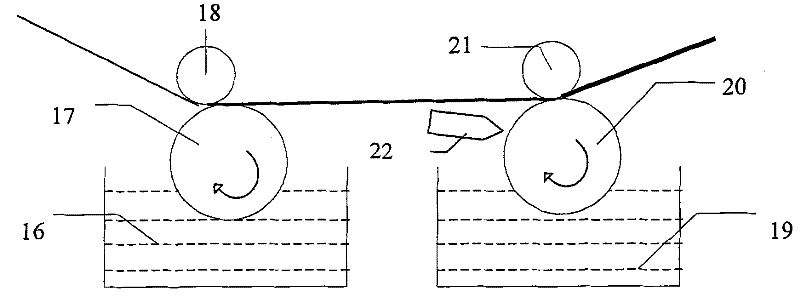

[0053] use image 3 With the shown device and operation, the anti-counterfeiting element 24 obtained by compounding according to the method of embodiment 1 or embodiment 2 is embedded in two layers of paper 23a and 23b in papermaking, and the Figure 4 The security paper shown.

[0054] The anti-counterfeiting paper can be banknote paper, valuable product packaging paper or cardboard, etc.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com