Raw material formula for producing sulfur microcapsules using melamine resins

A technology of melamine resin and microcapsules is applied in the field of raw material formulation of sulfur microcapsules, which can solve the problems of dangerous operation, equipment corrosion, high price, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] The quality of each component of the prepared single-shell sulfur microcapsules is as follows:

[0012]

[0013] The preparation method of single-shell sulfur microcapsules is as follows:

[0014] (1) Add 5.0g of melamine and 9.6g of 37% formaldehyde solution to a four-necked flask, add dropwise 10% sodium carbonate solution, adjust the pH to 8.5-9, keep at 60℃ and stir for 30min to prepare the melamine resin prepolymer body;

[0015] (2) Prepare 40.1g aqueous solution containing 0.5g polyvinyl alcohol, add 0.5g OP-10 surfactant, heat and stir to prepare an aqueous solution;

[0016] (3) Add 5.1 g of sublimed sulfur to the aqueous solution, shear and disperse it for 5 minutes with a shear emulsifier at 10000 rpm to obtain a sulfur dispersion suspension, and transfer the suspension and the melamine resin prepolymer to a four-necked flask in;

[0017] (4) Turn on the condensing reflux water device, add formic acid to adjust the pH to 5-6, stir at 350rpm, heat up to 60°C, and cure...

Embodiment 2

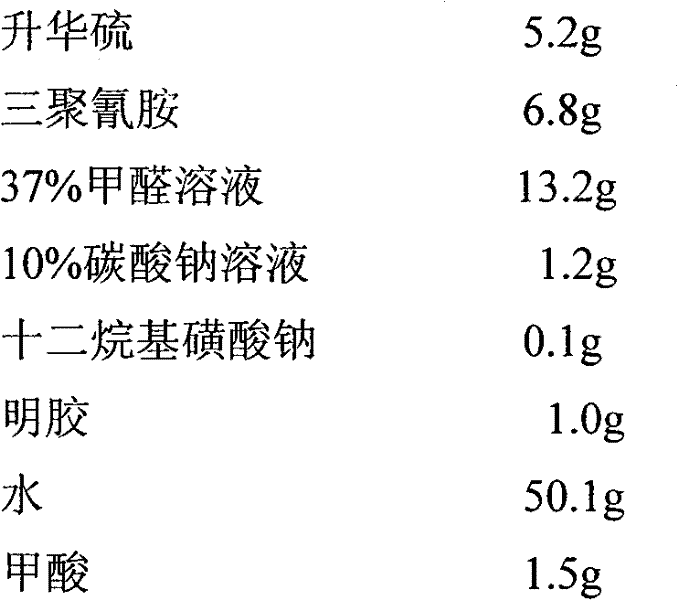

[0021] The quality of each component of the prepared single-shell sulfur microcapsules is as follows:

[0022]

[0023] The preparation method of single-shell sulfur microcapsules is as follows:

[0024] (1) Add 6.8g of melamine and 13.2g of 37% formaldehyde solution to a four-necked flask, add 10% sodium carbonate solution dropwise, adjust the pH to 8.5-9, stir and react at 60°C for 30min to prepare melamine resin prepolymer;

[0025] (2) Prepare 50.1g aqueous solution containing 0.5g gelatin, add 0.1g sodium dodecyl sulfonate surfactant, heat and stir to prepare an aqueous solution;

[0026] (3) Add 5.2 g of sublimed sulfur to the aqueous solution, shear and disperse it for 3 minutes with a shear emulsifier at 7500 rpm to obtain a sulfur dispersion suspension, and transfer the suspension and the melamine resin prepolymer to a four-necked flask in;

[0027] (4) Put on a condensing reflux water device, add formic acid to adjust the pH to 5-6, stir at 350rpm, heat up to 60°C, and cure t...

Embodiment 3

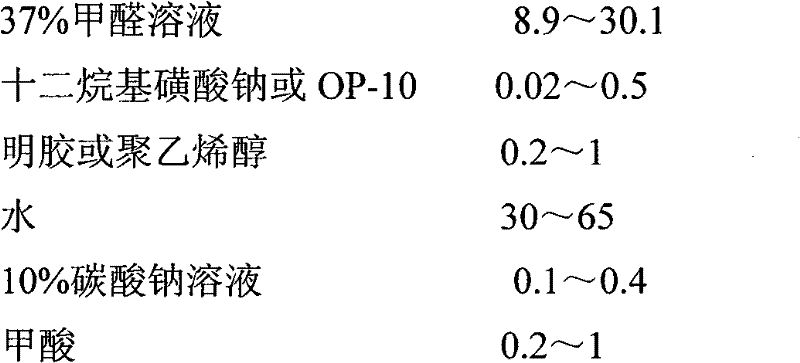

[0031] The quality of each component of the prepared single-shell sulfur microcapsules is as follows:

[0032]

[0033] The preparation method of single-shell sulfur microcapsules is as follows:

[0034] (1) Add 3.2g of melamine and 6.8g of 37% formaldehyde solution to a four-necked flask, add 10% sodium carbonate solution dropwise, adjust the pH to 8.5-9, stir and react at 60°C for 30min to prepare melamine resin prepolymer;

[0035] (2) Prepare an aqueous solution containing 0.5 g of gelatin, add 0.075 g of sodium dodecyl sulfonate surfactant, heat and stir to prepare an aqueous solution;

[0036] (3) Add 5.1 g of sublimed sulfur to the aqueous solution, shear and disperse it for 5 minutes with a shear emulsifier at 10000 rpm to obtain a sulfur dispersion suspension, and transfer the suspension and the melamine resin prepolymer to a four-necked flask in;

[0037] (4) Turn on the condensing reflux water device, add formic acid to adjust the pH value to 5-6, stir at 450rpm, heat up to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com