Multi-nozzle high-voltage electrostatic spinning apparatus added with electric field shielding device

A high-voltage electrospinning and electric field shielding technology, which is applied in the fields of magnetic field/electric field shielding, complete sets of equipment for the production of artificial wires, electrical components, etc., can solve the problems of incomplete superposition or mixing, weakened mechanical properties, and mutual incompatibility, etc., to achieve Good application promotion value, prevent mutual interference, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Co-laminated film of polyacrylonitrile microfibers and nanofibers

[0033] Dissolve 2g of polyacrylonitrile (Mw=100,000) in 18g of N,N-dimethylformamide to form a 10% mass concentration solution, and keep stirring for 24 hours for later use;

[0034] Dissolve 4g of polyacrylonitrile (Mw=100,000) in 16g of N,N-dimethylformamide to form a 20% mass concentration solution, and keep stirring for 24 hours for later use;

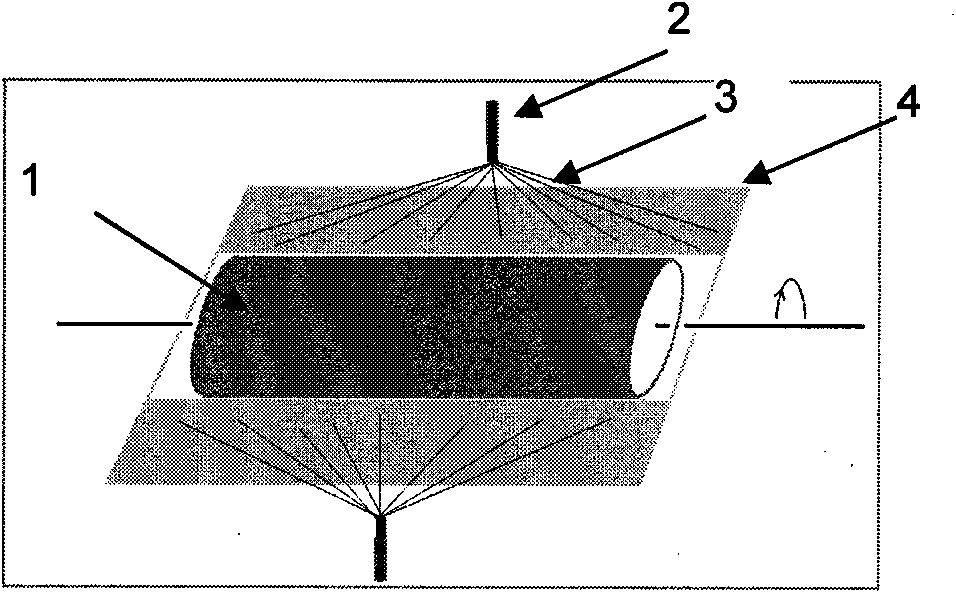

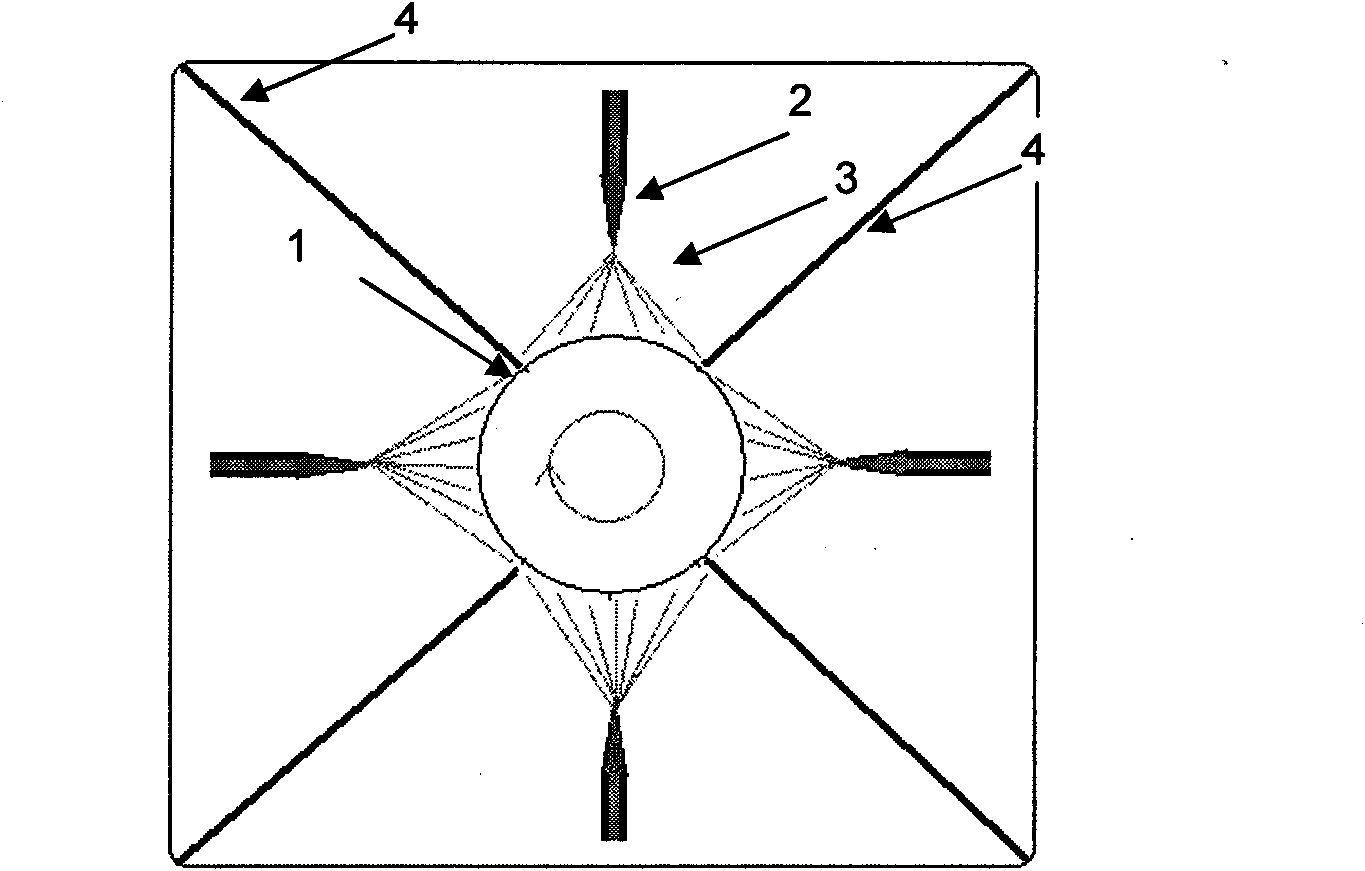

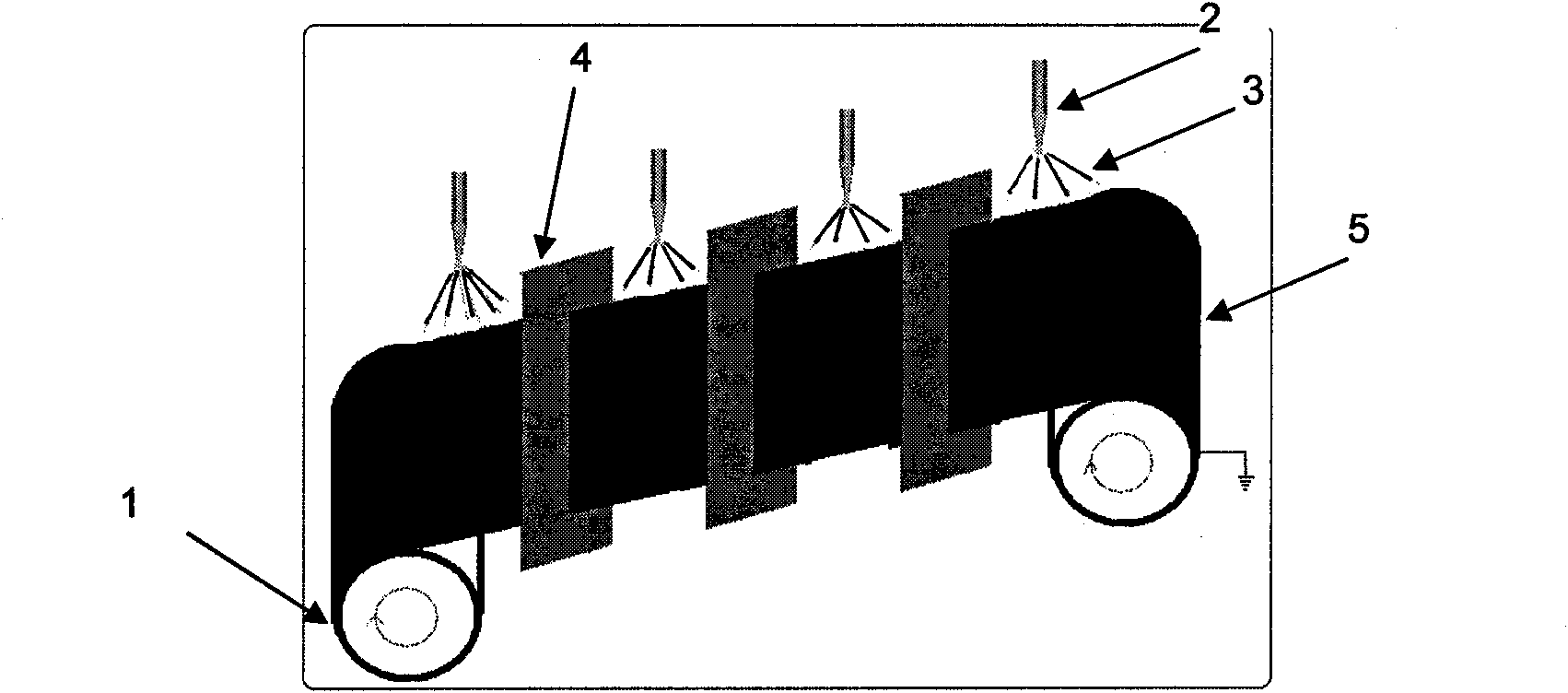

[0035] Put the above solutions into two medical syringes respectively, each with a needle as the nozzle of electrospinning, the nozzle is respectively connected to the anode of the high voltage power supply, the roller (conductive cylinder with aluminum foil) is used as the receiver, and the ground is used as the voltage zero point. Install a hollowed-out Bakelite insulation board with a thickness of 1cm on the central axis of the roller, place the nozzles on both sides of the insulation Bakelite board respectively, keep the Bakelite insulation board and nozzl...

Embodiment 2

[0037] As shown in Example 1, the insulating plate wherein is replaced by a plexiglass plate, and the obtained test results are similar;

Embodiment 3

[0039] As shown in Example 1, the insulating plate wherein is replaced by a tetrafluoroplastic plate, and the obtained test results are similar;

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com