On-line detection method of free chlorine during synthesis process of hydrogen chloride

A technology of synthesis process and detection method, applied in chlorine/hydrogen chloride and other directions, to achieve the effects of stable production, lightening work intensity and ensuring detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Free chlorine online detection method in the hydrogen chloride synthesis process of the present invention is as follows:

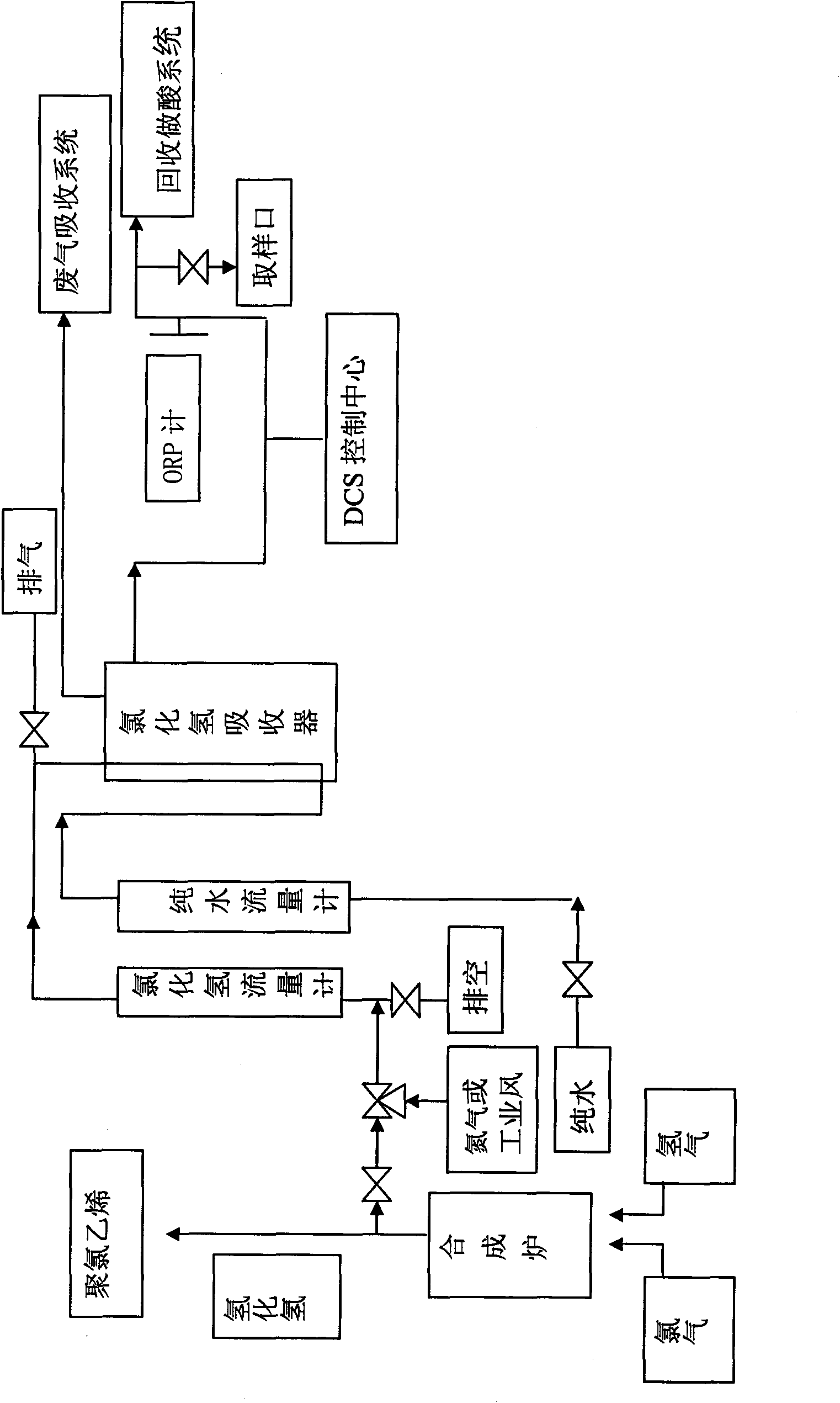

[0017] (1) As shown in Figure 1, chlorine and hydrogen are fully combusted in the hydrogen chloride synthesis furnace, and the hydrogen chloride drawn from the hydrogen chloride main pipe first passes through the three-way valve, and then enters the absorber through flowmeter metering and control of a flow rate of 150L / h; pure water The flow rate is controlled by a flowmeter to 1000L / h (determined according to the volume of the absorber) and then enters the absorber, where a dilute hydrochloric acid solution with a mass concentration of 0.1% is made; the gas tail gas passing through the absorber is injected into the waste gas recovery system for recycling.

[0018] (2) The overflow of the dilute hydrochloric acid solution in the absorber is detected by the ORP meter, and the detected dilute acid solution is injected into the recovery system to recycl...

Embodiment 2

[0021] Free chlorine online detection method in the hydrogen chloride synthesis process of the present invention is as follows:

[0022] (1) As shown in Figure 1, chlorine and hydrogen are fully combusted in the hydrogen chloride synthesis furnace, and the hydrogen chloride drawn from the hydrogen chloride main pipe first passes through the three-way valve, and then enters the absorber through flowmeter metering and control of a flow rate of 1500L / h; pure water The flow rate is controlled by a flowmeter to 300L / h (determined according to the volume of the absorber) and then enters the absorber, where a dilute hydrochloric acid solution with a mass concentration of 5% is made; the gas tail gas passing through the absorber is injected into the waste gas recovery system for recovery.

[0023] (2) The overflow of the dilute hydrochloric acid solution in the absorber is detected by the ORP meter, and the detected dilute acid solution is injected into the recovery system to be recycl...

Embodiment 3

[0026] Free chlorine online detection method in the hydrogen chloride synthesis process of the present invention is as follows:

[0027] (1) As shown in Figure 1, chlorine and hydrogen are fully combusted in the hydrogen chloride synthesis furnace, and the hydrogen chloride drawn from the hydrogen chloride main pipe first passes through the three-way valve, and then enters the absorber through flowmeter metering and control of a flow rate of 1000L / h; pure water The flow rate is controlled by a flowmeter to 200L / h (determined according to the volume of the absorber) and then enters the absorber, where a dilute hydrochloric acid solution with a mass concentration of 10% is made; the gas tail gas passing through the absorber is injected into the waste gas recovery system for recycling.

[0028] (2) The overflow of the dilute hydrochloric acid solution in the absorber is detected by the ORP meter, and the dilute acid solution after detection is injected into the recovery system to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com