Method and device for the regeneration of a particle filter arranged in the exhaust gas train of an internal combustion engine

一种颗粒过滤器、排气管路的技术,应用在排气装置、消音装置、机器/发动机等方向,能够解决零件密集、大结构体积、不可实际使用等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

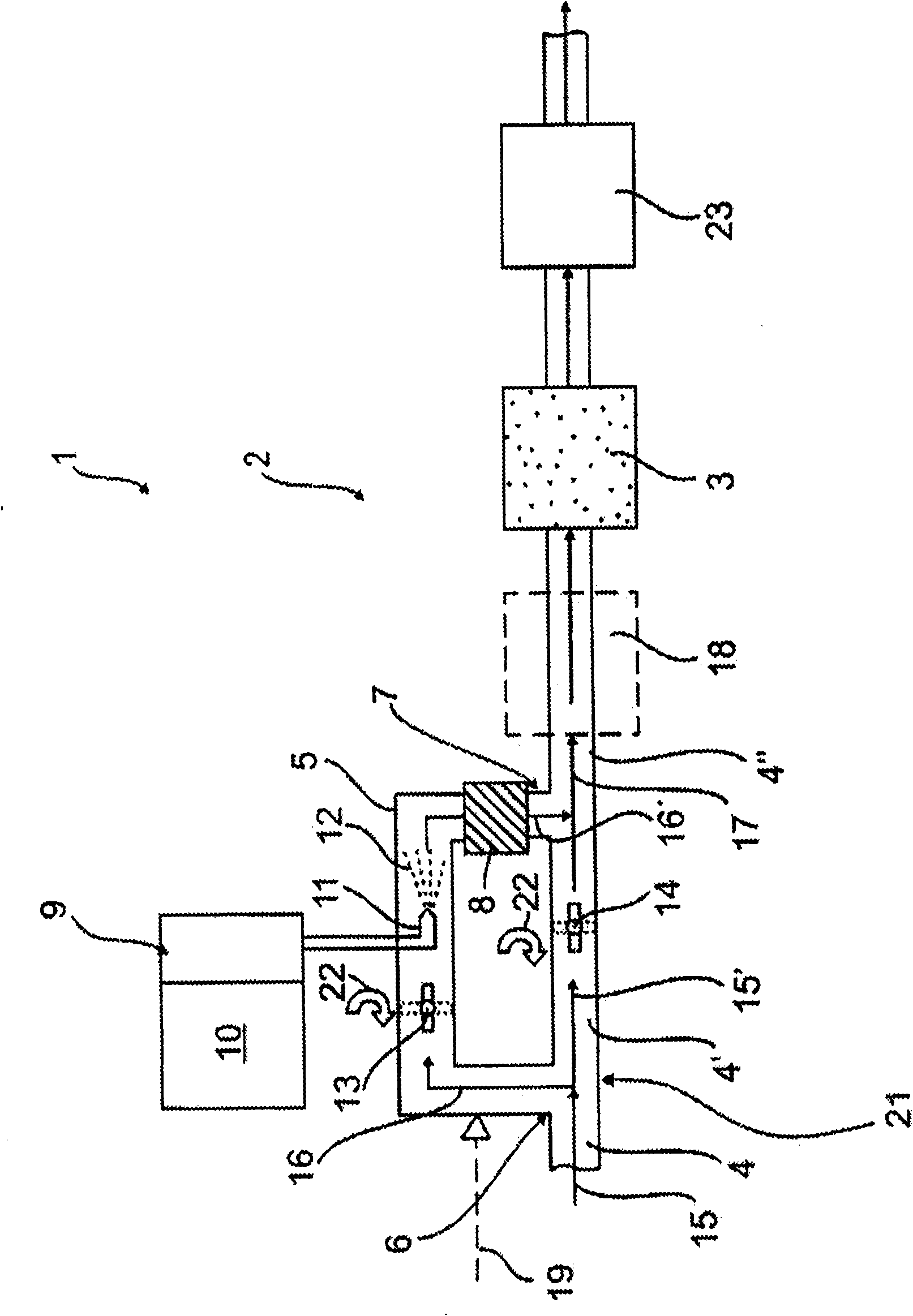

[0044] In the case of the example of the invention, a NO is also connected downstream of the particle filter 3 x - A reduction catalyst 23, such as an SCR catalyst.

[0045] Additionally, as in figure 1 Drawn only by dashed lines in , an additional HC-oxidation catalyst 18 can be provided downstream of the inlet point 7 and upstream of the particle filter 3 , whereby high hydrocarbon concentrations can be reliably avoided downstream of the particle filter 3 . Alternatively or additionally, the particle filter 3 itself can also be equipped with corresponding active components for this purpose.

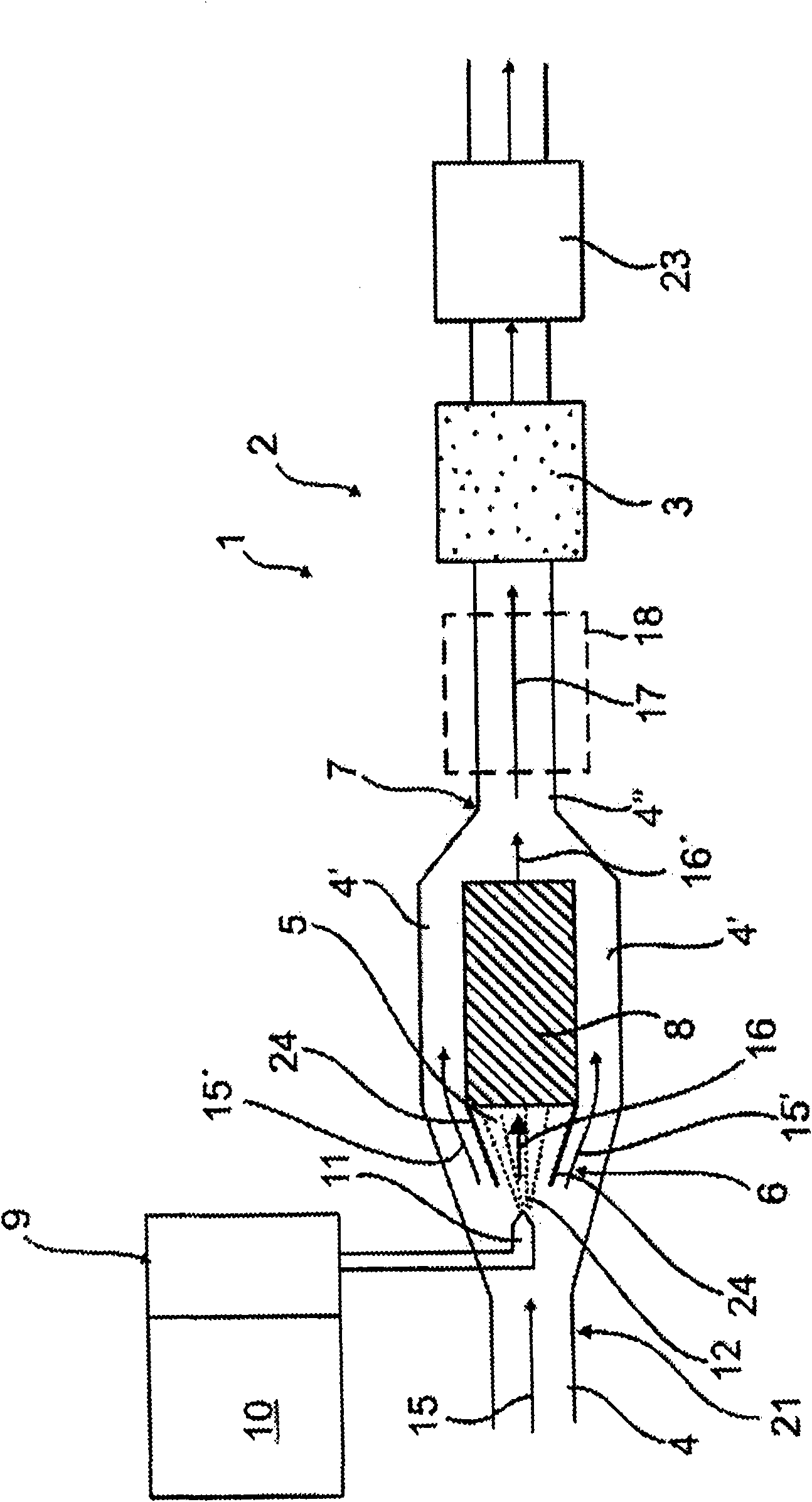

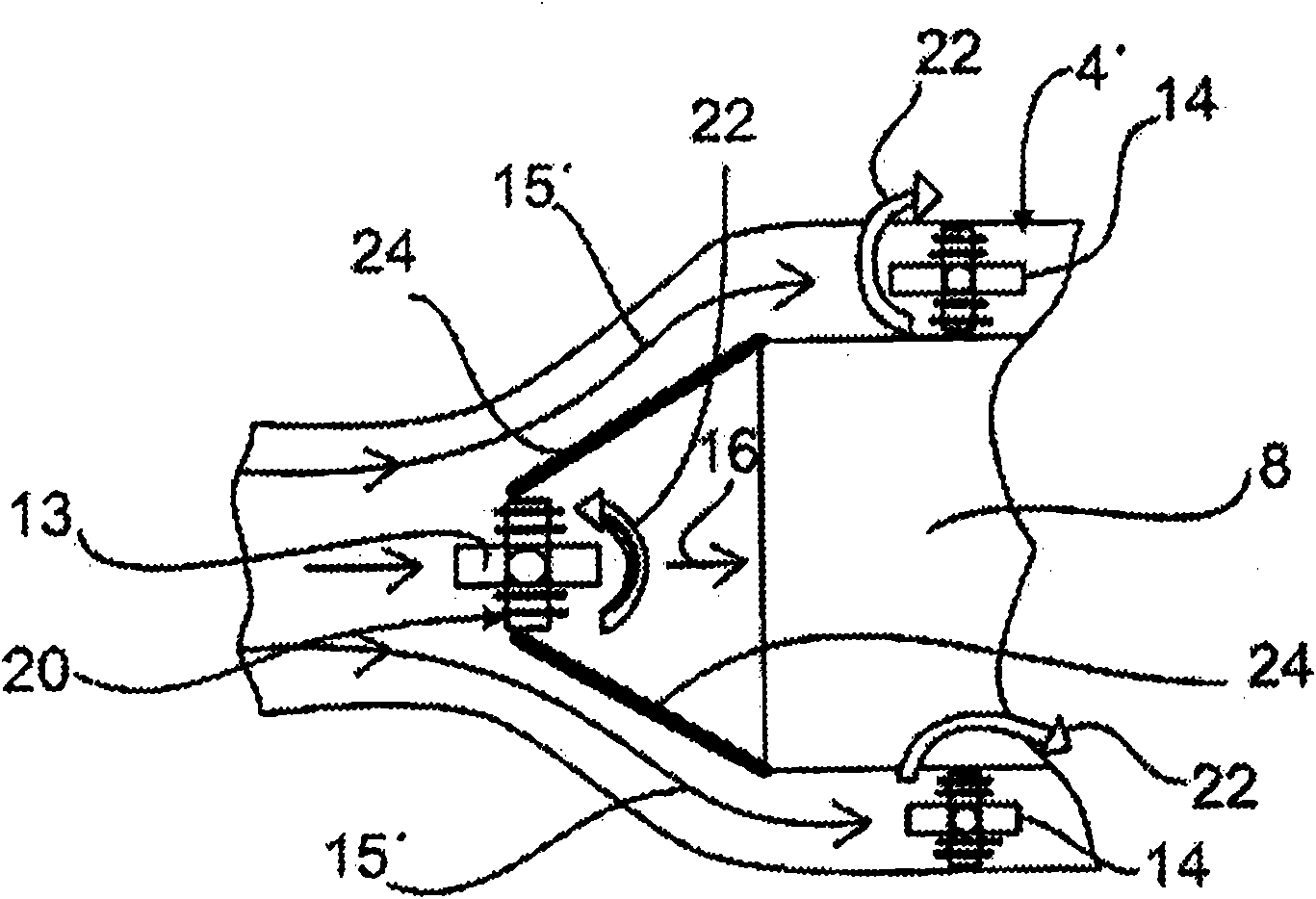

[0046] exist figure 2 A second embodiment of the regeneration device 1 according to the invention is shown schematically and exemplarily in which, for a particularly compact and thus space-saving construction, the HC-oxidation catalyst 8 is mounted and accommodated in an annular ring surrounding the HC- Area of the untreated exhaust gas line of the oxidation catalytic converter 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com