Phototonus resin combination, solder resist combination for printed wiring board and printed wiring board

A photosensitive resin, printed wiring board technology, used in printed circuits, printed circuit manufacturing, optics, etc., can solve the problems of discoloration, decline in reflectivity, and decline in commodity value, and achieve less discoloration and reflectivity. The effect of exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

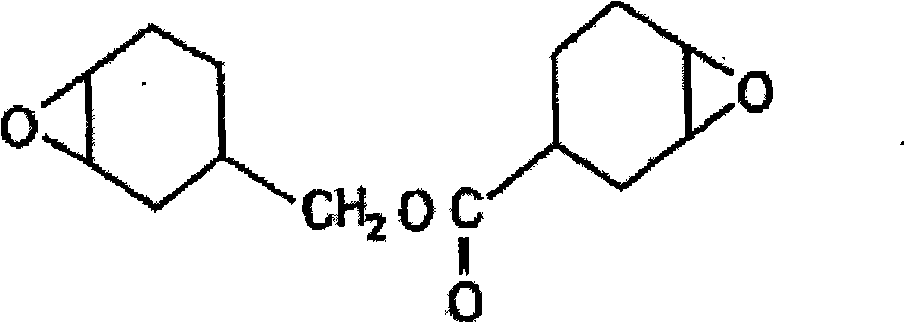

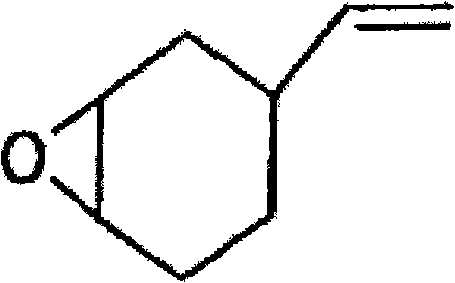

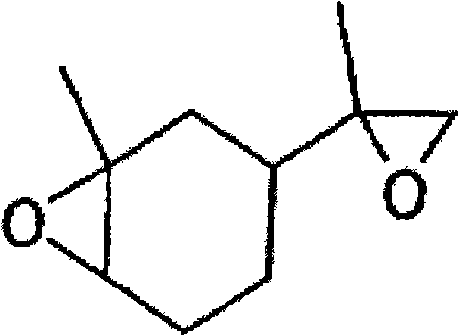

Method used

Image

Examples

Embodiment 1

[0088] Each component was mixed in the following mass ratio to prepare a solder resist composition. The detailed ingredient amounts are as follows.

[0089] (A) "CYCLOMER-P(ACA)Z-251" manufactured by Daicel Chemical Industry Co., Ltd. 40% by mass

[0090] (B) 0.05% by mass of trimethylolpropane trithiopropionate

[0091] (C) Acylphosphine-based photopolymerization initiator ("IRGACURE 819" manufactured by Ciba Specialty Chemicals Co., Ltd.) 0.3% by mass

[0092] (D) Diluent (DPHA) 5% by mass

[0093] (E) Rutile-type titanium oxide ("CR-80" manufactured by Ishihara Sangyo Co., Ltd. (Ishihara Sangyo Co., Ltd.)) 35% by mass

[0094] (F) Epoxy-based thermosetting compound ("EPICLON 860" manufactured by Dainippon Ink Chemical Industry Co., Ltd. (Dainippon Ink Chemical Industry Co., Ltd.)) 10% by mass

[0095] The rest is as follows:

[0096] Antifoaming agent, KS-66 (manufactured by Shin-Etsu Silicone Co., Ltd. (Shin-Etsu Silicone Co., Ltd.))

[0097] Thixotropic agent, AEROS...

Embodiment 2

[0106] Compositions with the following compositions were produced in the same manner as in Example 1. However, it is the same as in Example 1 except (A)-(F).

[0107] (A) "CYCLOMER-P(ACA)Z-251" manufactured by Daicel Chemical Industry Co., Ltd. 40% by mass

[0108] (B) 1% by mass of trimethylolpropane trithiopropionate

[0109] (C) Acylphosphine photopolymerization initiator ("IRGACURE 819" manufactured by Ciba Specialty Chemicals Co., Ltd.) 0.3% by mass

[0110] (D) Diluent (DPHA) 5% by mass

[0111] (E) Rutile-type titanium oxide ("CR-80" manufactured by Ishihara Sangyo Co., Ltd.) 35% by mass

[0112] (F) Epoxy thermosetting compound ("Epiclon 860" manufactured by Dainippon Ink Chemical Industry Co., Ltd.) 10% by mass

Embodiment 3

[0114] Compositions with the following compositions were produced in the same manner as in Example 1. However, it is the same as in Example 1 except (A)-(F).

[0115] (A) "CYCLOMER-P(ACA)Z-251" manufactured by Daicel Chemical Industry Co., Ltd. 40% by mass

[0116] (B) 5% by mass of trimethylolpropane trithiopropionate

[0117] (C) Acylphosphine photopolymerization initiator ("IRGACURE 819" manufactured by Ciba Specialty Chemicals Co., Ltd.) 0.3% by mass

[0118] (D) Diluent (DPHA) 5% by mass

[0119] (E) Rutile-type titanium oxide ("CR-80" manufactured by Ishihara Sangyo Co., Ltd.) 35% by mass

[0120] (F) Epoxy thermosetting compound ("Epiclon 860" manufactured by Dainippon Ink Chemical Industry Co., Ltd.) 10% by mass

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com