Straight wire PCB plane spiral coil primary current sensor

A planar spiral coil and current sensor technology, applied in the direction of inductors, fixed inductors, fixed signal inductors, etc., can solve the problems of anti-electromagnetic interference technology to be improved, low measurement accuracy, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

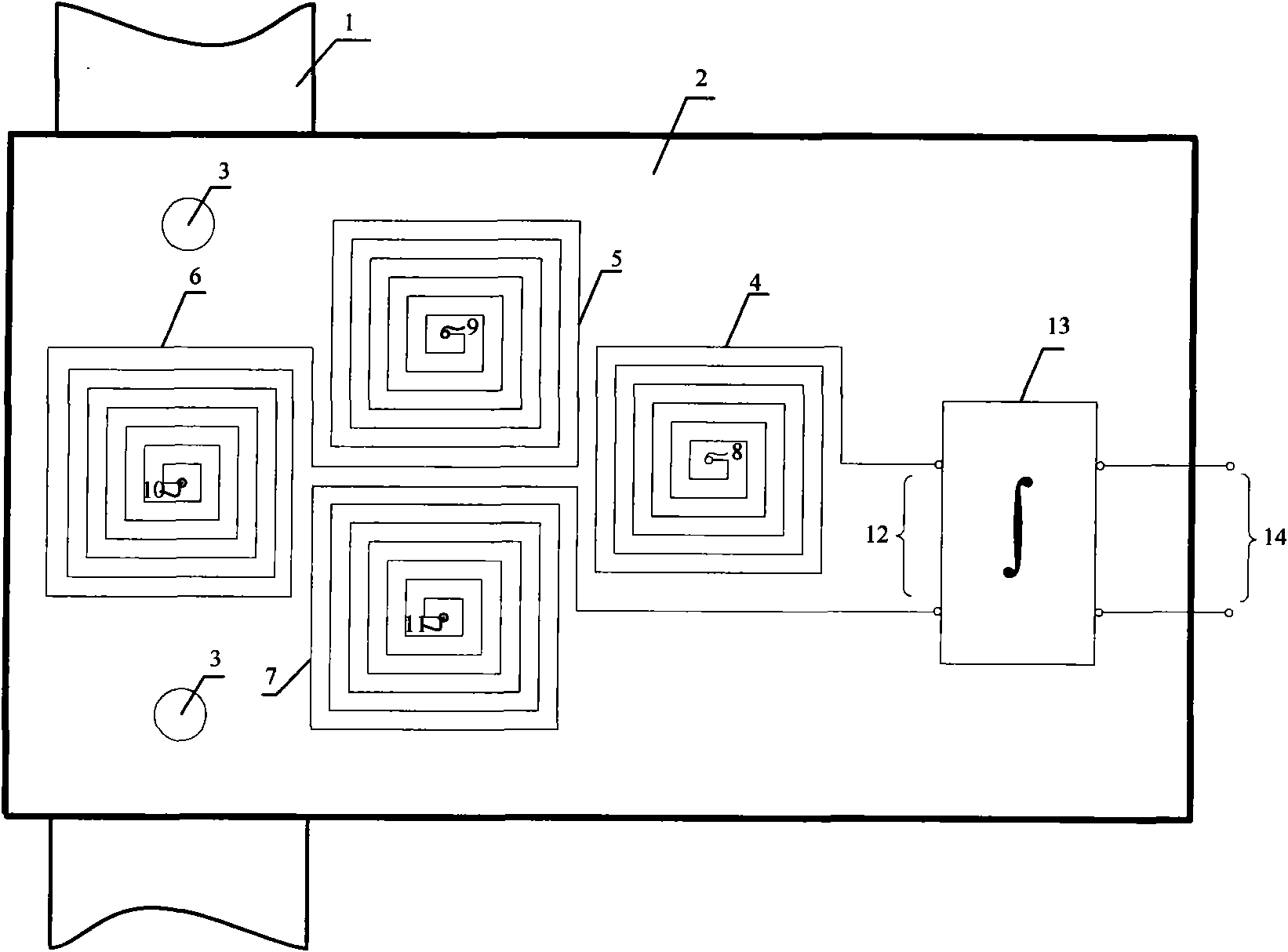

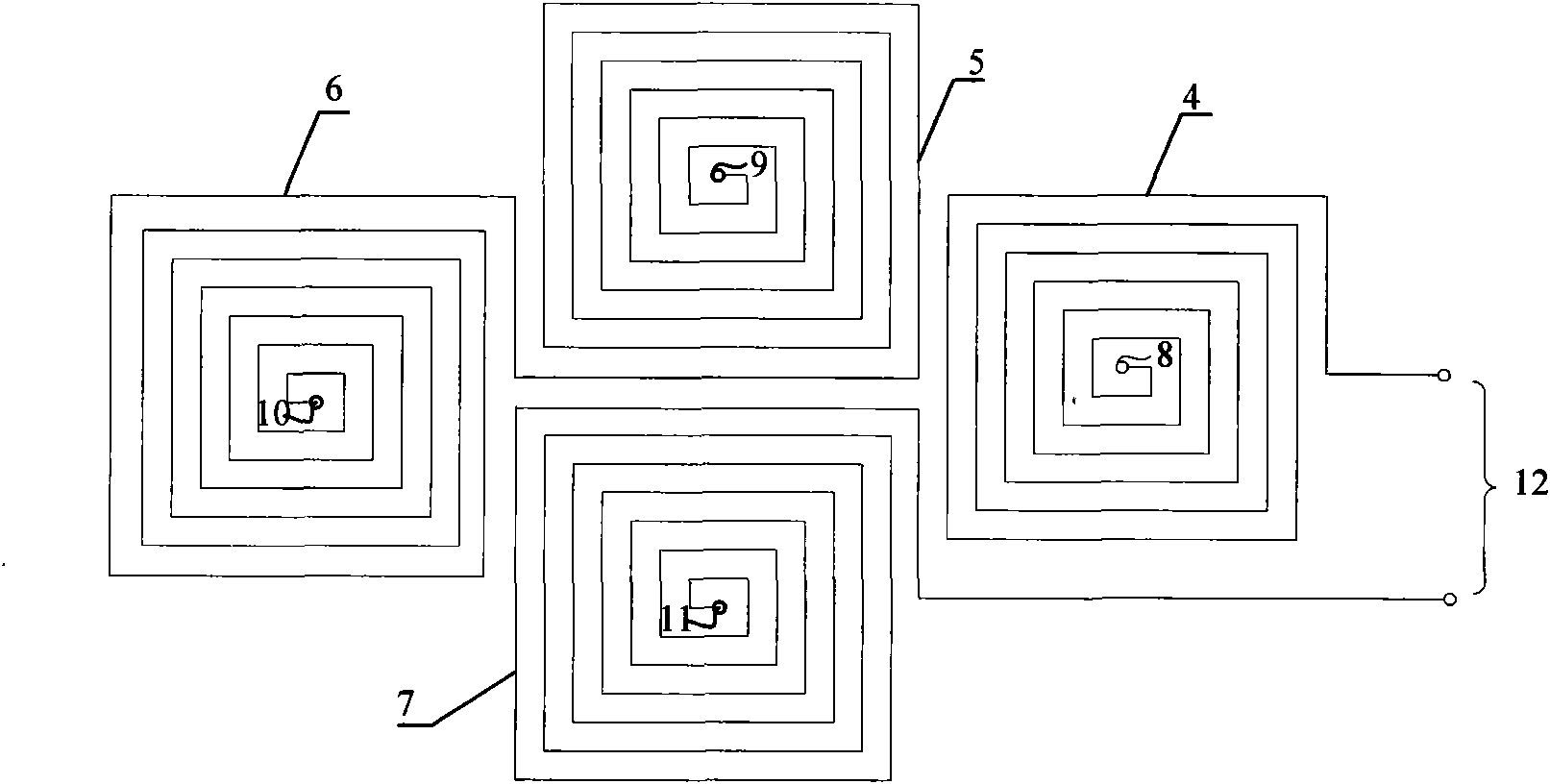

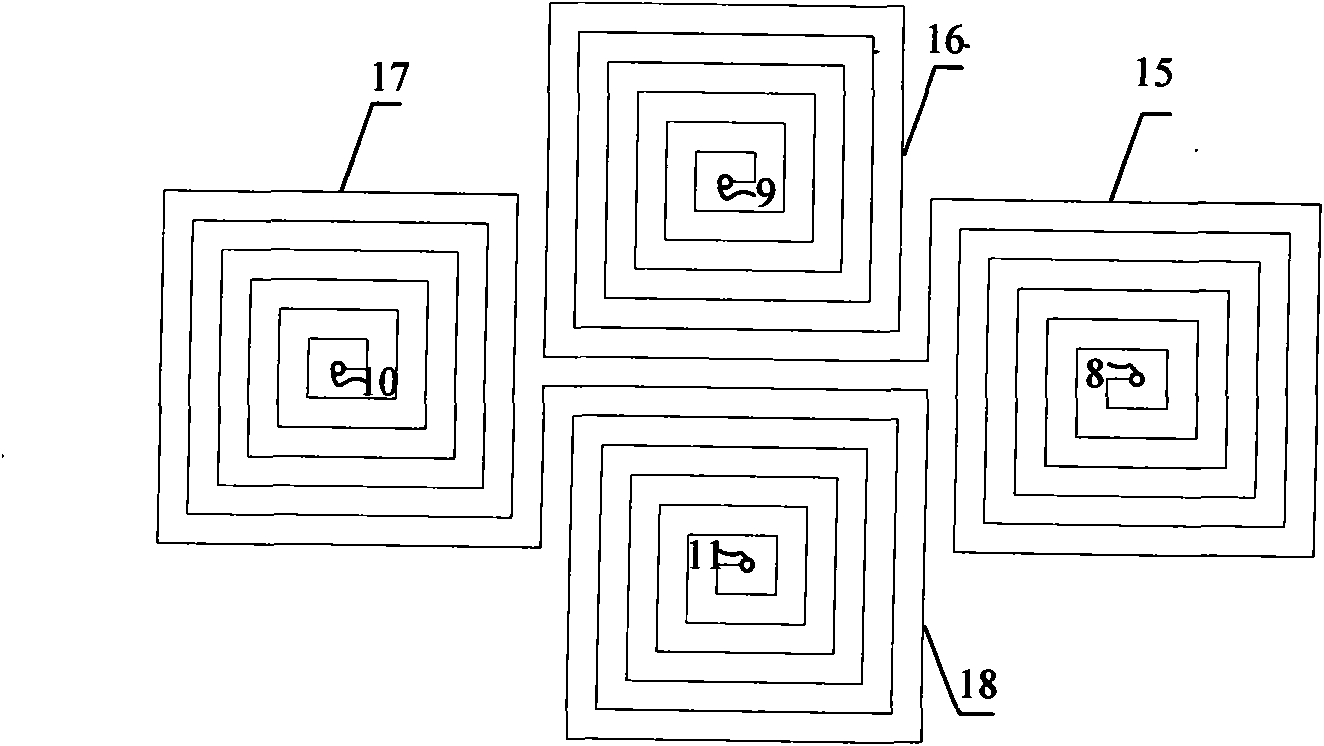

[0021] see figure 1 , in the figure 1 is the primary current straight wire, the cross section of the straight wire can be rectangular or circular, and both have a central axis; 2 is the PCB board printed with 4 planar spiral coils; 3 is the fastening between the PCB board and the primary straight wire Bolts; 4, 5, 6, and 7 are the same four planar spiral coils on the upper layer of the PCB; 8, 9, 10, and 11 are the magnetic center connection vias of the four planar spiral coils on the upper layer and the lower layer of the PCB; 12 is the PCB board The output terminal of the induced potential of the secondary coil; 13 is the integral amplifier; 14 is the output voltage terminal of the primary current sensor. If the cross-section of primary straight wire 1 is circular or rectangular, open a rectangular groove along the central axis. The four sides of the groove are required to be smooth and flat. In the groove, make the upper and lower edges of the straight wire groove coincide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com