Grinding machine equipment for grinding internal surface of column

An inner surface and grinding technology, which is applied in the direction of grinding/polishing equipment, machine tools designed for grinding the rotating surface of workpieces, and parts of grinding machine tools, can solve the problems of increasing maintenance costs, increasing impact force of supporting structures, and paper machine Intensified vibration and other problems, to achieve the effect of reducing machine maintenance costs, improving motion accuracy, and improving paper quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

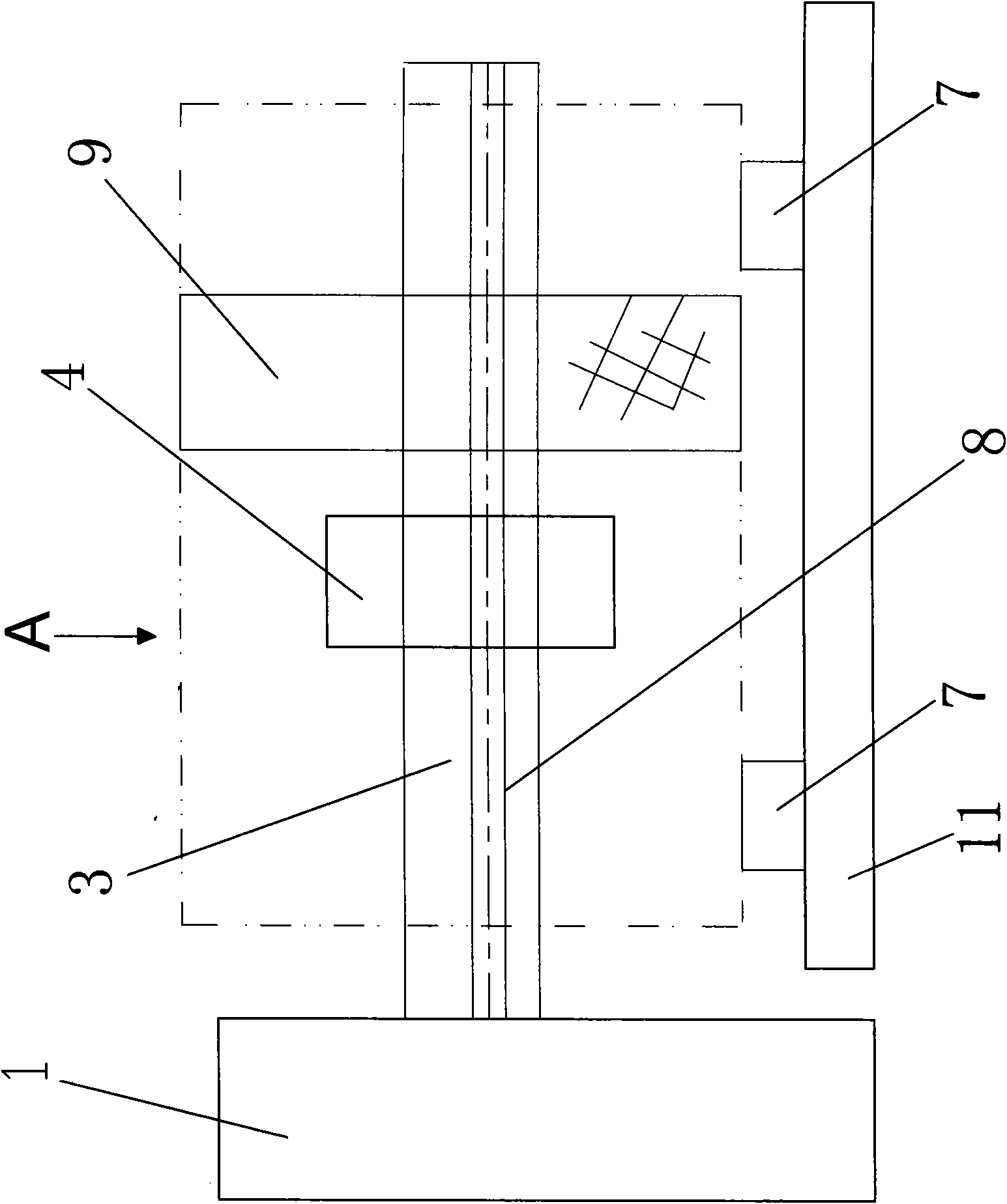

[0015] Embodiment: A grinding machine equipment for grinding the inner surface of a cylinder, including a bed head 1 (fixed on the ground through the feet), a bed (fixed on the ground through the feet), a roller frame 7, a feed mechanism 8, and a knife bar mechanism 4 and the coolant mechanism, the head of the bed 1 is composed of a motor gear transmission system and a control system, the bed includes a tool beam 3, a first guide rail 11 and a second guide rail 12, and the feed mechanism 8 includes a lead screw with an external thread and an internal tool The kinematic pair of the screw thread (the lead screw and the kinematic pair realize the axial advance and retreat of the tool bar mechanism relative to the workpiece), the kinematic pair is sleeved on the lead screw through the engagement of the internal and external threads, and the feed mechanism 8 is also provided with The structure that can advance and retreat radially relative to the workpiece (for general technology, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com