Separation membrane complex, and method for production of separation membrane complex

A manufacturing method and technology for separation membranes, applied in chemical instruments and methods, semi-permeable membrane separation, membranes, etc., can solve the problems of membrane deterioration and deterioration of the separated body, etc., and achieve excellent results, low total pressure loss, and high selectivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

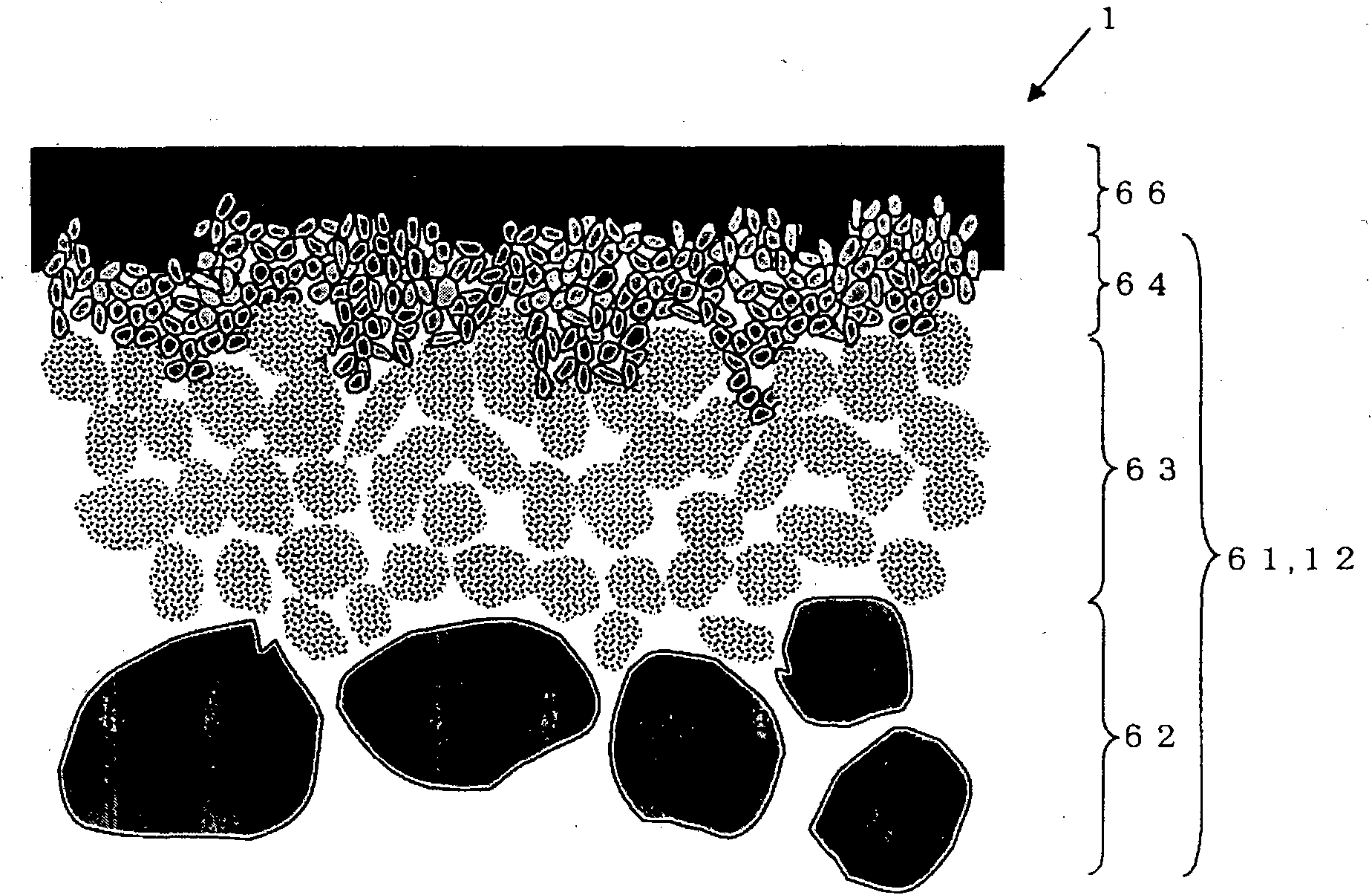

[0074] After molding and firing by extrusion molding, a monolithic substrate with an average particle diameter of 10 to 100 μm and an average pore diameter of 1 to 30 μm is prepared. Then, while adjusting the thickness of the membrane with the time of membrane formation, the average particle diameter of the aggregates composed of primary particles with a diameter of 0.01 to 1 μm is set to Alumina particles (secondary particles) of 0.3 to 10 μm are deposited and then fired to form an intermediate layer having a thickness of 10 μm and an average particle diameter of 0.1 to 3 μm. Next, while adjusting the thickness of the film at the time of film formation, aluminum oxide particles with an average particle diameter of 0.03 to 1 μm were further deposited on the intermediate layer by the filtration film formation method, and then fired to form a film with a thickness of 10 μm. A surface layer having an average particle diameter of 0.01 to 0.5 μm yields a porous body.

[0075] Then...

Embodiment 2

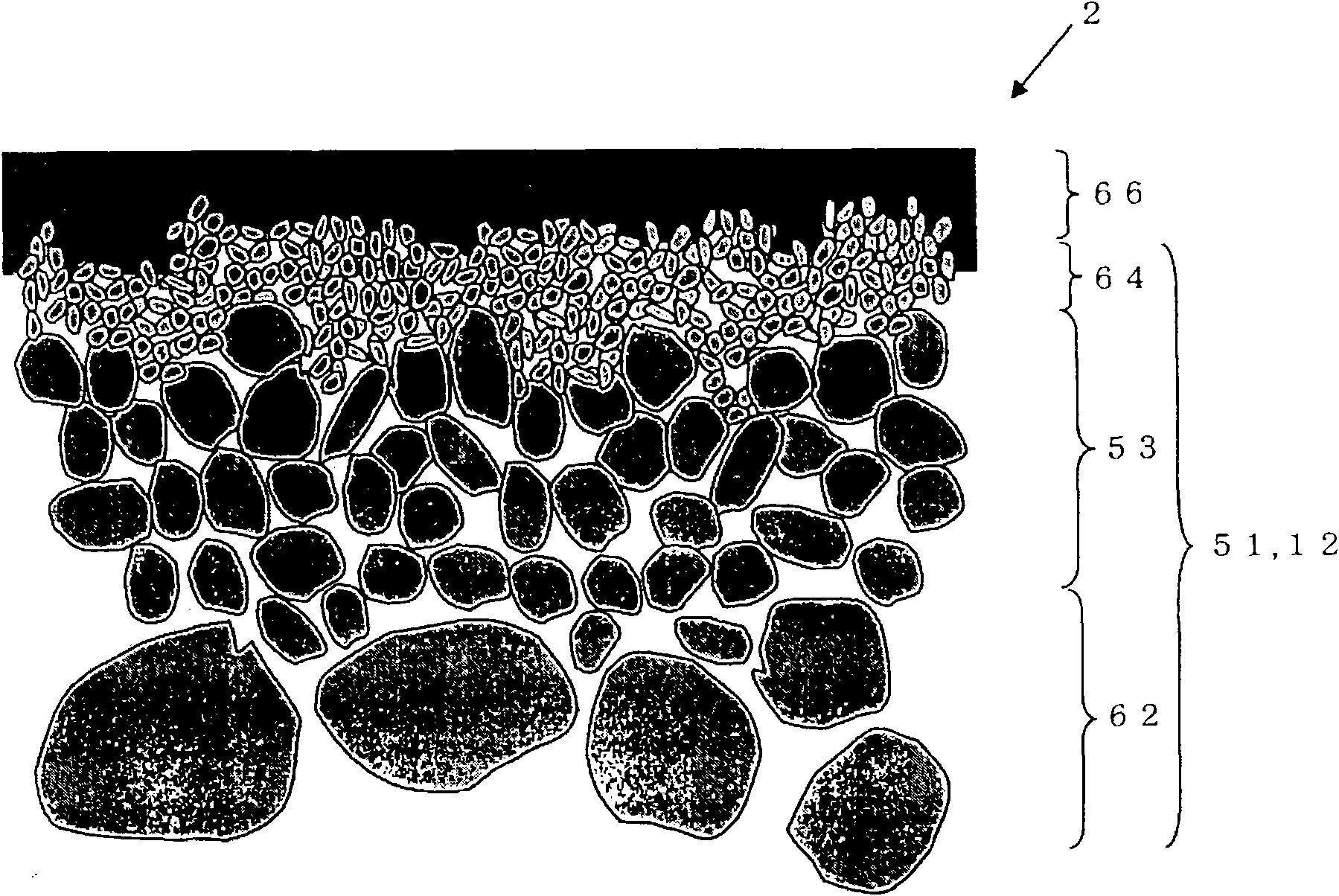

[0078] A separation membrane composite was produced in the same manner as in Example 1 except that the thickness of the intermediate layer was 100 μm, and evaluated by the water-alcohol permeation vaporization separation method under the same conditions as in Example 1. Table 1 shows the particle morphology (agglomerates or dense bodies) of the interlayer, thickness of the interlayer, percolation vaporization separation performance (separation coefficient, flux) and pressure loss. in addition, Figure 4 A photograph showing a cross section of a porous body after forming a carbon film. In Example 2, two porous bodies were produced under the same conditions, Figure 4 It is a photograph cut using one of the porous bodies.

Embodiment 3

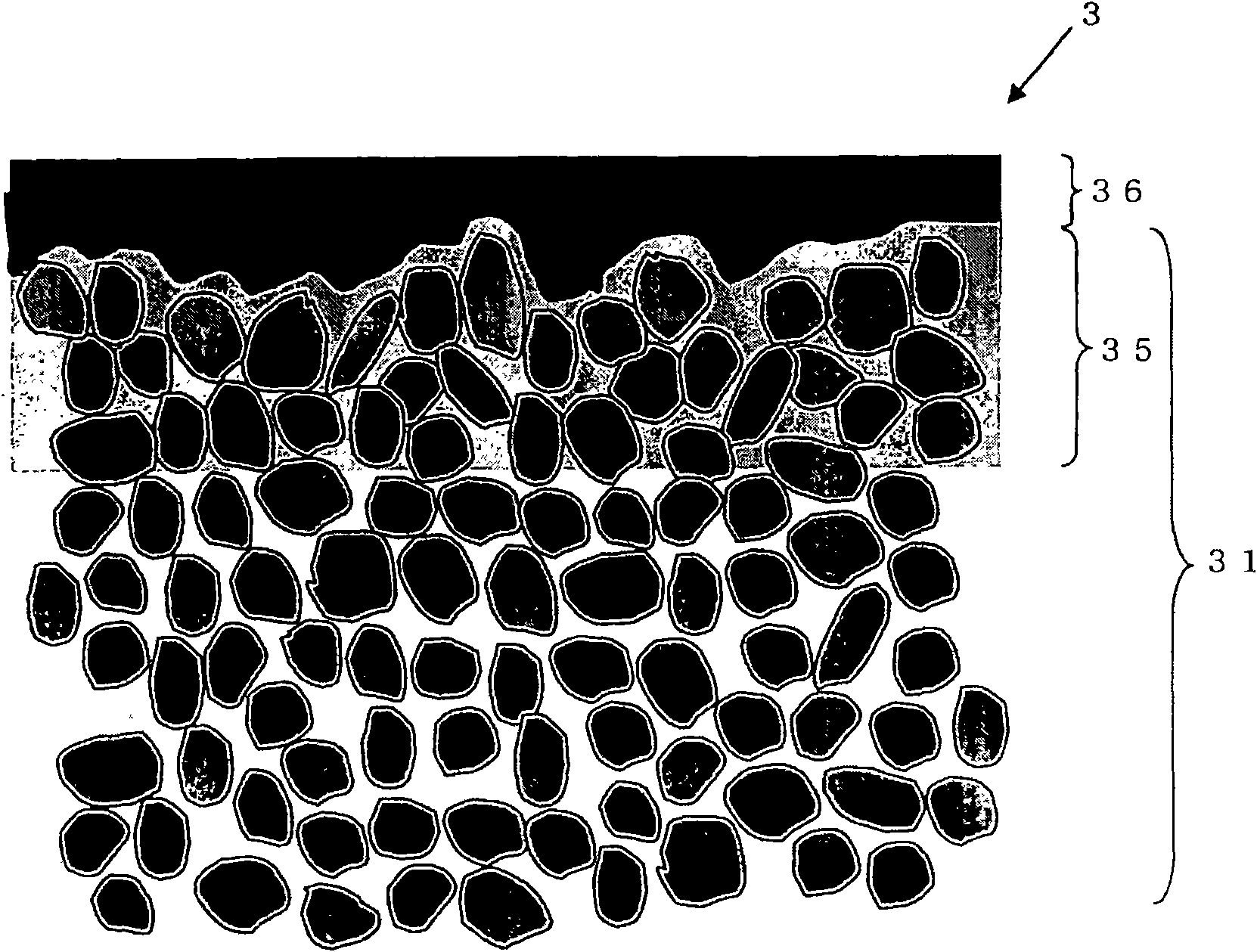

[0080] Except using the aluminum oxide particle that is made of dense body when forming the intermediate layer and the thickness of the intermediate layer is 50 μ m, make separation membrane complex body similarly with embodiment 1, under the same conditions as embodiment 1, by water- Ethanol permeation vaporization separation method to evaluate. Table 1 shows the particle morphology (agglomerates or dense bodies) of the interlayer, thickness of the interlayer, percolation vaporization separation performance (separation coefficient, flux) and pressure loss.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com