An ion-conductive polymer-based separation membrane element and its membrane separation module

An ionic conductivity, membrane separation module technology, applied in semi-permeable membrane separation, membrane technology, osmotic/dialysis water/sewage treatment, etc. Scope and other issues, to achieve the effect of improving separation efficiency and economic applicability, promoting large-scale application and development, increasing packing density and effective area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

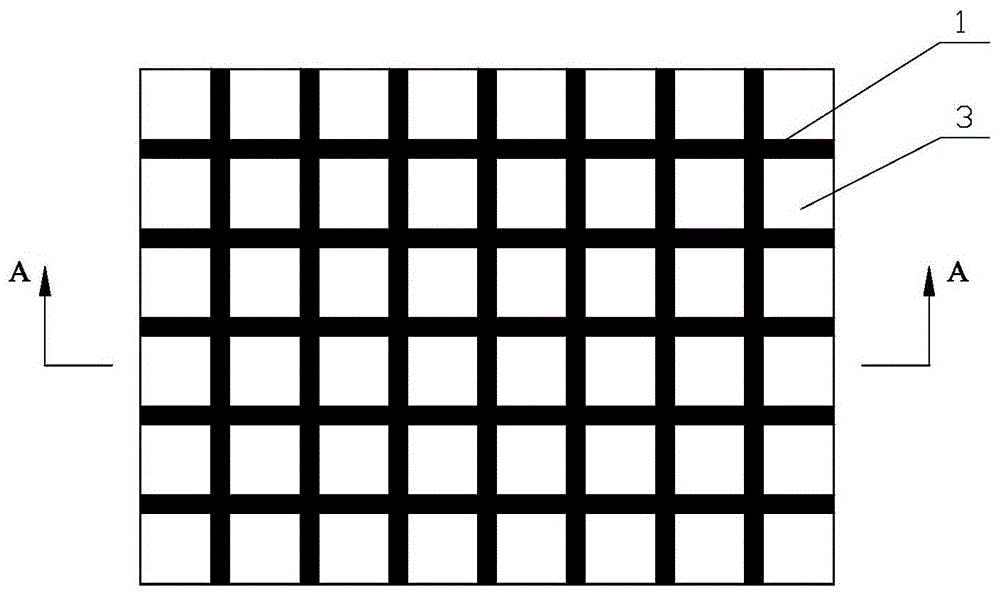

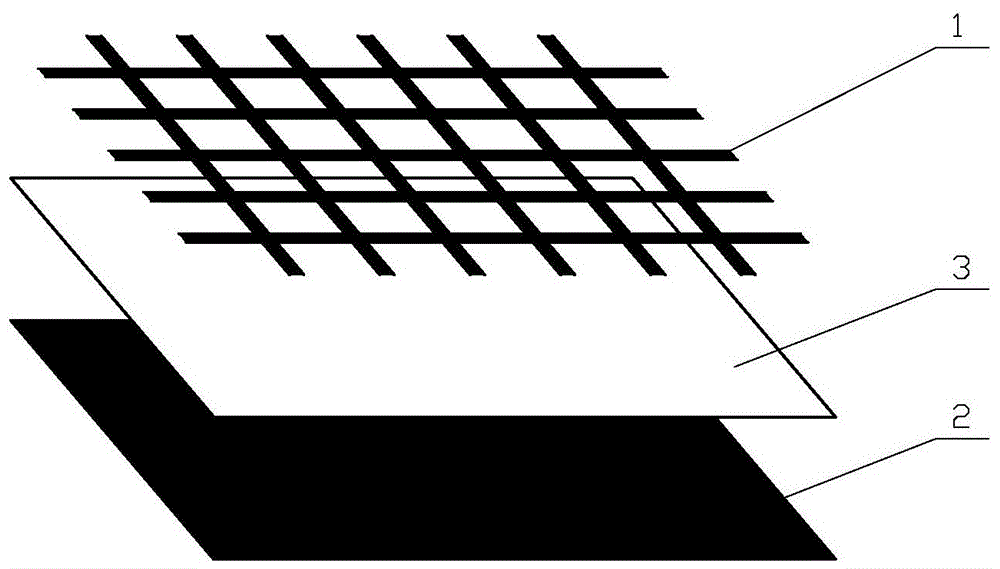

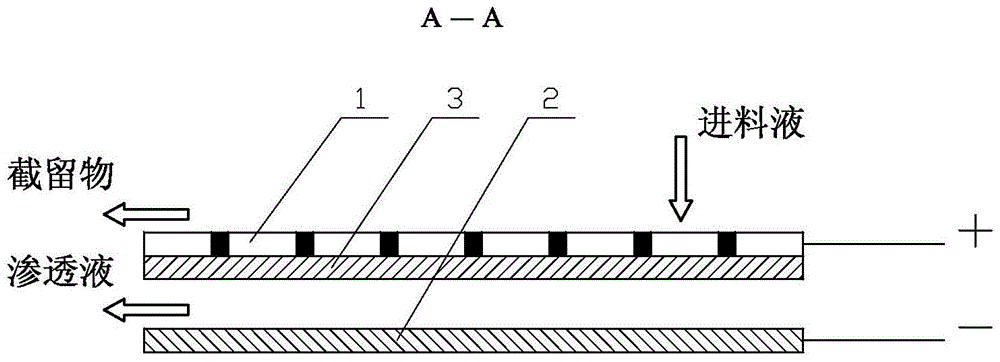

[0027] Figure 1 ~ Figure 3 Shown is an embodiment of an ion-conductive polymer-based separation membrane element of the present invention, including an electronically-conductive grid membrane 1 , an electrode plate 2 , and a polymer-based separation membrane 3 with ion conductivity.

[0028] Such as figure 1 with figure 2 As shown, the separation membrane 3 is flat, and at least one surface plane is a functional layer for separation. At least the functional layer of the separation membrane 3 has ion conductivity, and the resistivity is 3-2000Ω·cm.

[0029] The thickness of the functional layer of the separation membrane 3 is 0.1-200 μm, and the pore diameter is 0-100 nm. The separation membrane 3 can be a dense membrane, such as an ion exchange membrane with ion conductivity, a charged reverse osmosis membrane, a charged nanofiltration membrane, or a porous membrane, such as a charged ultrafiltration membrane or a charged microfiltration membrane.

[0030] The material of...

Embodiment 2

[0035] Figure 4 Shown is the embodiment of the plate-and-frame ion-conductive polymer-based membrane separation module of the present invention, such as Figure 4 As shown, it is a plate-and-frame module composed of one or more membrane separation units 4 . The membrane separation unit 4 is composed of the two separation membrane elements of the first embodiment, and the electrode plates 2 of the two separation membrane elements are the same electrode plate. The membrane separation units 4 are arranged in parallel at intervals.

Embodiment 3

[0037] Figure 5 Shown is the embodiment of the roll-type ion-conductive polymer-based membrane separation module of the present invention, which is composed of one or more than one membrane separation unit 4 (see Figure 4 ) composed of roll components. The three sides of the membrane separation unit 4 are sealed and one side is open to form a separation membrane bag; each separation membrane bag is stacked at intervals, and one side of the opening is fixedly connected to the central tube with a through hole in the tube wall (see Figure 5 ), the bag body is coiled around the central tube to form a roll-type membrane separation module.

[0038] When in use, the feed liquid enters from one end of the module along the axial direction, passes through the interception and separation of the separation membrane 3, and the permeate passes through the separation membrane 3, passes through the gap with the electrode plate 2, and flows into the through hole from the opening side of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com