Hydrogen producing apparatus, method of operating hydrogen producing apparatus and fuel cell power generating system

A generating device and operating technology, applied in fuel cells, solid electrolyte fuel cells, separation methods, etc., can solve problems such as fuel cells not getting power generation, starting time becomes longer, steam carbon ratio increases, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

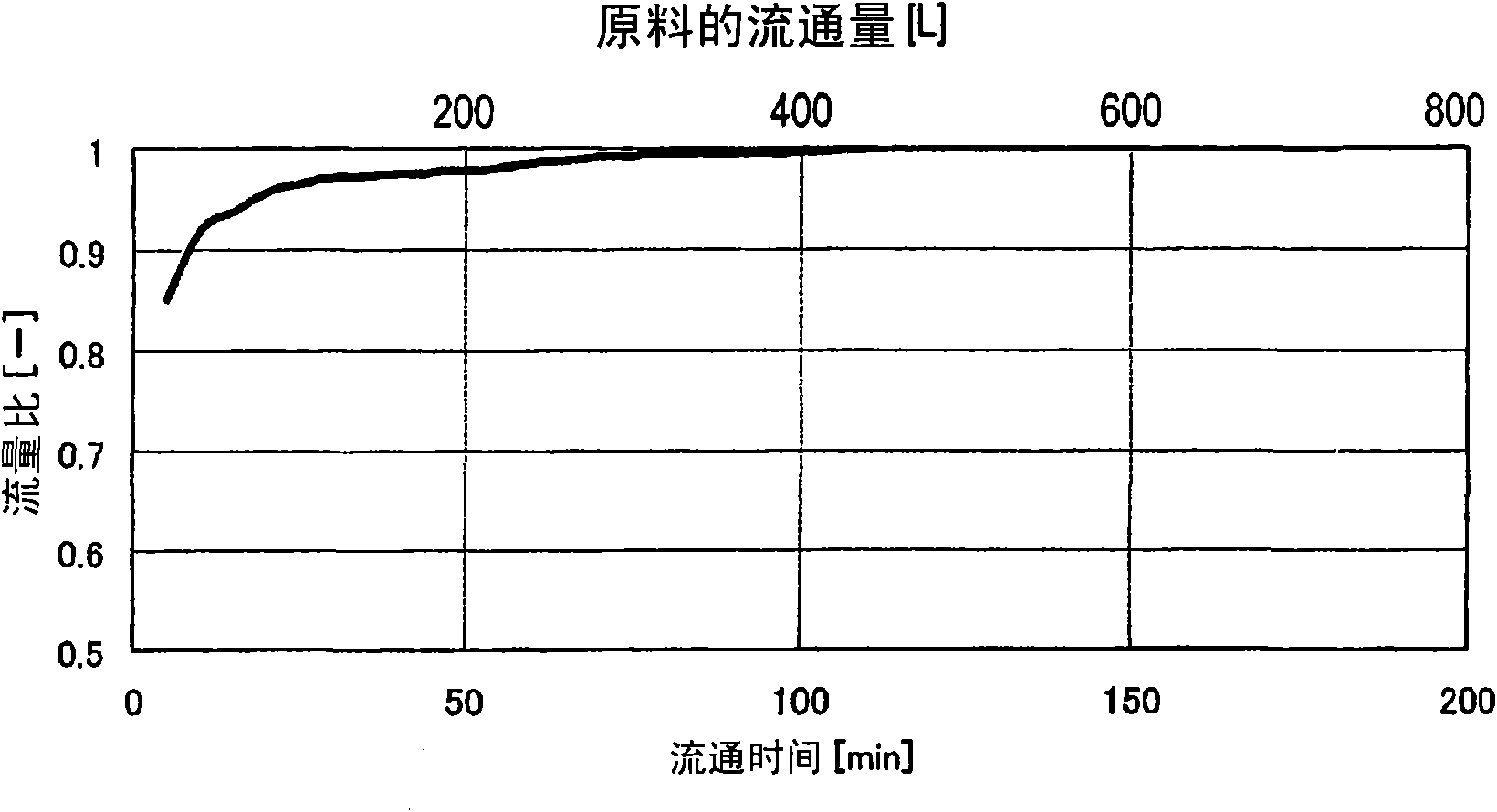

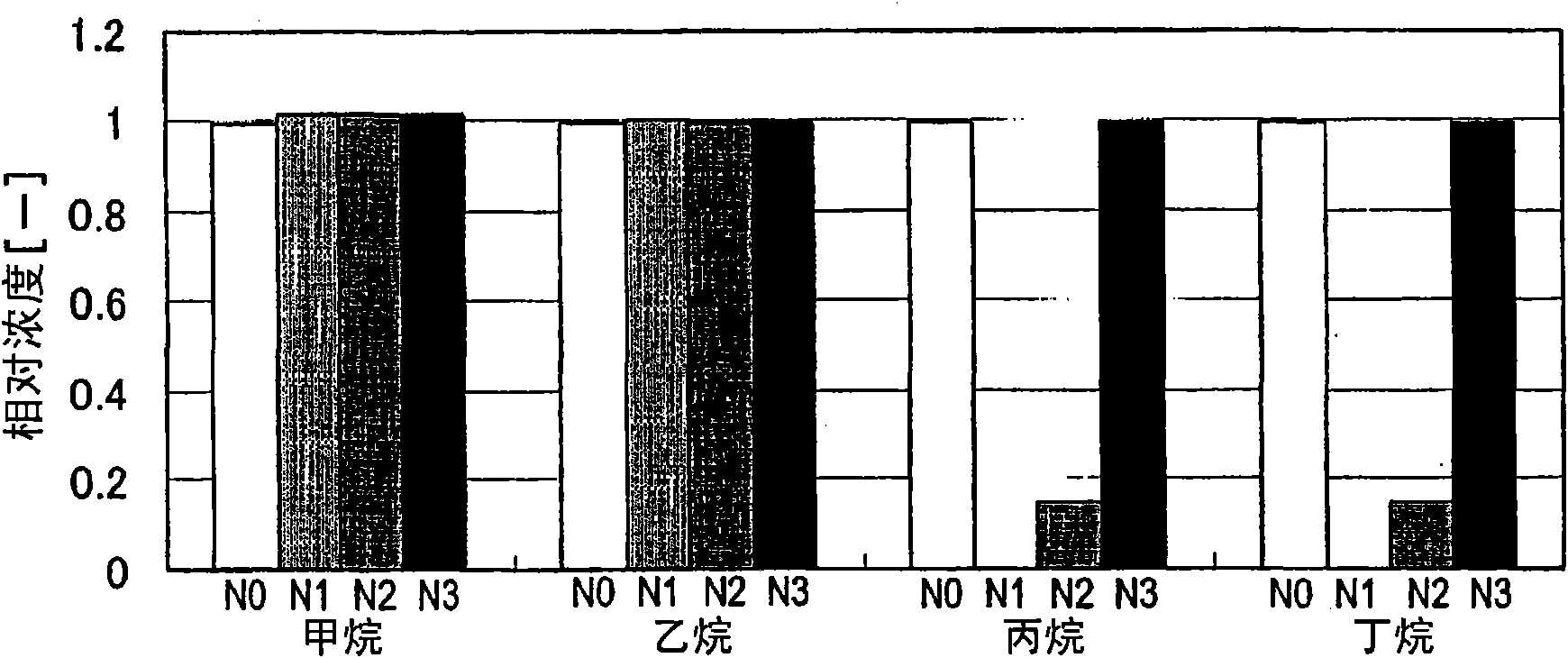

[0098] The hydrogen generator of the present embodiment is a device for generating a hydrogen-containing gas using a hydrocarbon-based raw material containing a sulfur component, and uses an adsorption desulfurization unit that adsorbs a sulfur component in order to remove the sulfur component from the raw material. The adsorption desulfurization unit is detachably held in the holding mechanism provided in the hydrogen generator, and when the adsorption capacity for sulfur components decreases, only a new adsorption desulfurization unit or an adsorbent in the adsorption desulfurization unit (adsorption desulfurization unit) is appropriately replaced. agent). Instead, regeneration of the adsorption desulfurization unit may be performed. In addition, it is preferable that the adsorptive desulfurization unit has an adsorbent mainly composed of zeolite. If a zeolite-based adsorbent is used, desulfurization can be performed at normal temperature, and the handling is simple, and re...

no. 2 approach

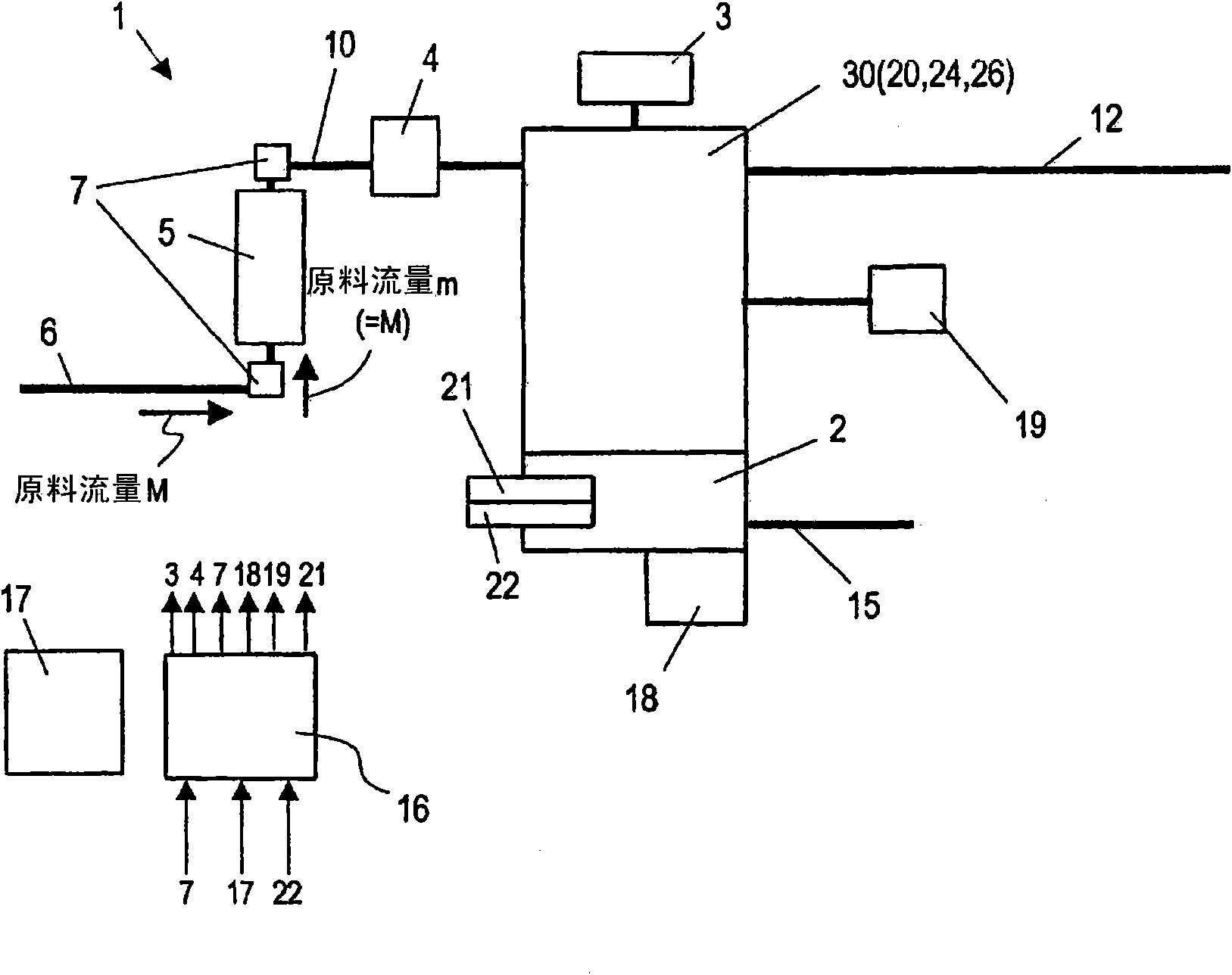

[0160] Figure 8 It is a configuration diagram illustrating a second embodiment of the hydrogen generator of the present invention. The hydrogen generator of the present embodiment is similar to that in that part of the raw material supplied from the gas infrastructure line can be sent to the combustor as combustion gas without passing through the adsorption desulfurization unit. Figure 4 The hydrogen generator 1 shown is different.

[0161] refer to Figure 4 At the same time, in the hydrogen generator 1, the raw material that has passed through the adsorption desulfurization unit 5 can be sent to the burner 2 to be combusted together with the hydrogen exhaust gas (auxiliary combustion). However, the gas combusted in the combustor 2 may contain odorizing components, and does not need to pass through the adsorption desulfurization unit 5 . Therefore, in the hydrogen generator of the present embodiment, the raw material before passing through the adsorption desulfurization ...

no. 3 approach

[0167] Hereinafter, a third embodiment of the hydrogen generator of the present invention will be described with reference to the drawings.

[0168] Figure 9 It is a block diagram showing the configuration of a fuel cell power generation system using the hydrogen generator of this embodiment. Figure 10 is the same as Figure 9 Flowchart of the content of the control program related to the replacement and regeneration of odorizing component removal parts in the hydrogen generator.

[0169] Figure 9 The illustrated fuel cell power generation system 500 has: a fuel cell 150 ; a hydrogen generator 200 ; and an oxidant gas supply device 160 . The structure of the hydrogen generator 200 will be described in detail later.

[0170]The fuel cell 150 includes a polymer electrolyte fuel cell in this embodiment. A polymer electrolyte fuel cell is formed into a fuel cell stack by stacking and fastening a plurality of battery cells. Each battery cell has: an MEA (not shown) in whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com