Tunnel magnetoresistive thin film and magnetic multilayer film formation apparatus

A technology of tunnel magnetoresistance and tunnel barrier layer is applied in the field of tunnel magnetoresistance film and magnetic multilayer film production device, and can solve the problem of extreme reduction of MR ratio and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

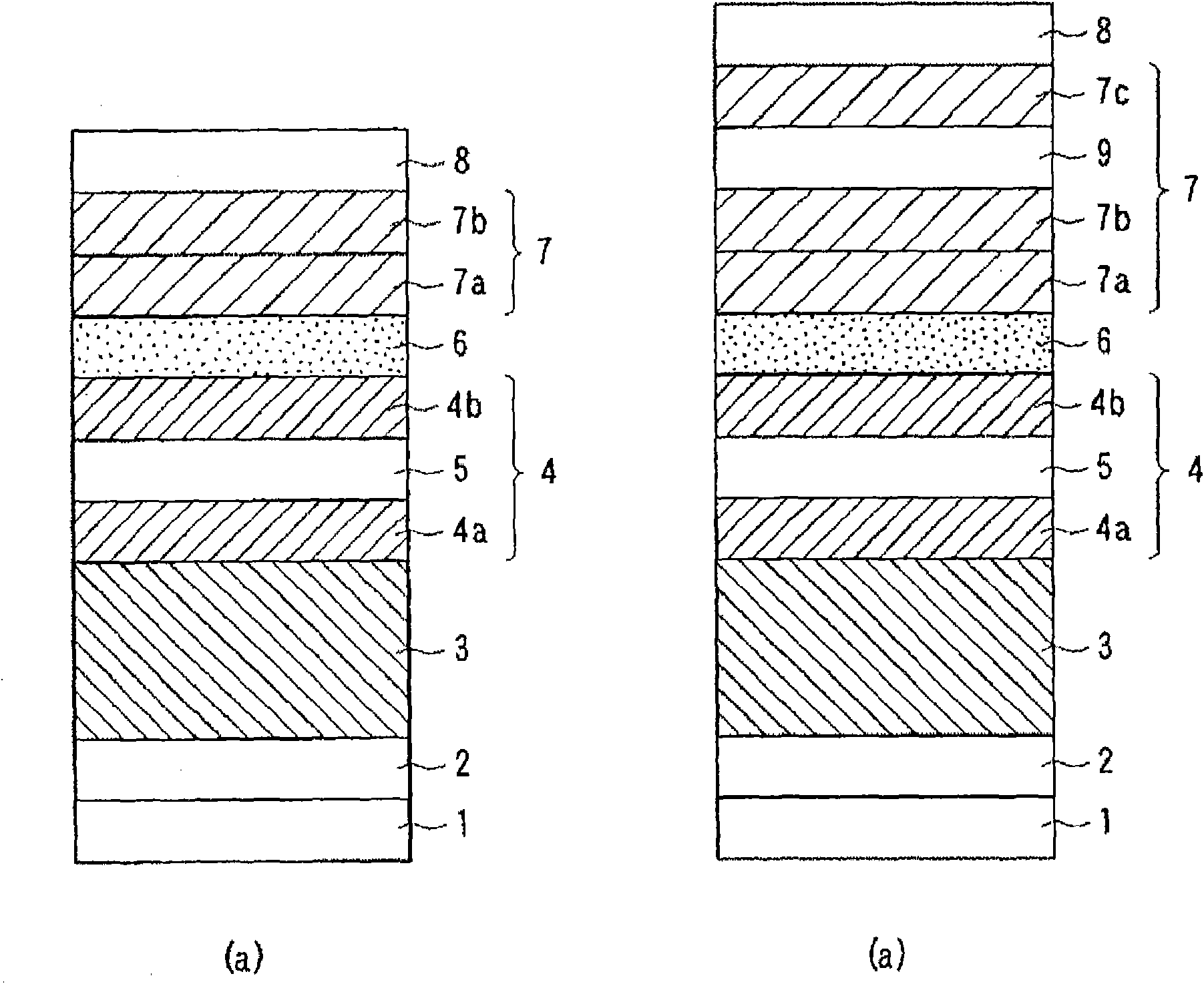

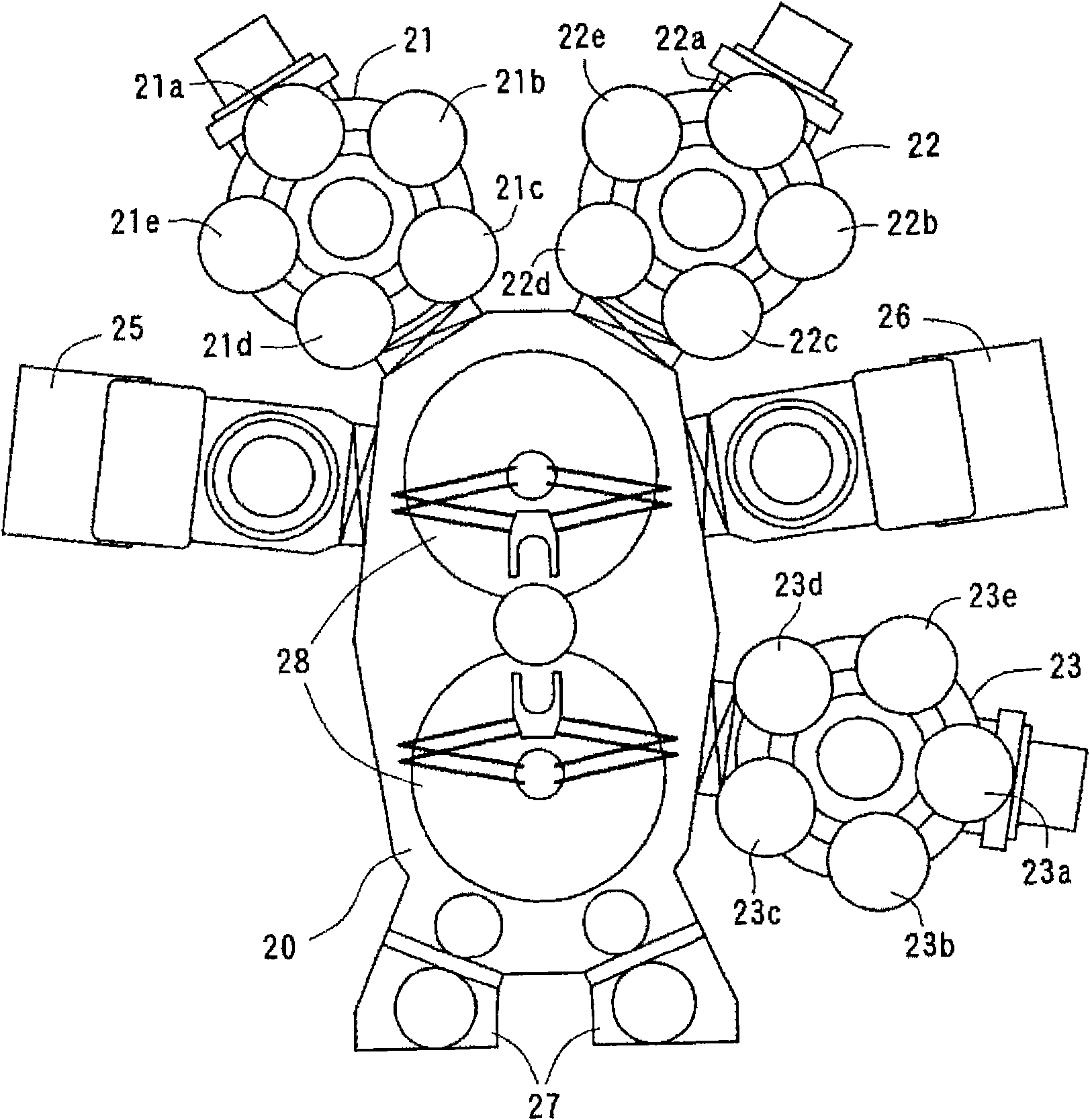

[0157] use figure 2 The device shown, making figure 1 A bottom-type spin-valve tunnel magnetoresistive thin film having a film structure shown in (a). In this example, the buffer layer 2 is Ta (10nm), the antiferromagnetic layer 3 is PtMn (15nm), and the magnetization pinned layer 4 is a laminated iron pinned layer composed of CoFe (2.5nm) / Ru (0.85nm) / CoFeB (3nm). layer, the tunnel barrier layer 6 is MgO (15nm). In addition, as the magnetization free layer 7 , CoNiFeB having a body-centered cubic structure is first formed into a film, and then NiFe with a face-centered cubic structure is formed into a film while maintaining the state at the time of film formation. As protective layer 8 , a stacked structure of Ta (10 nm) / Ru (7 nm) was used.

[0158] In addition, the first magnetization free layer 7a uses (Co 70 Fe 30 ) 96 B 4 , the second magnetization free layer 7b uses Ni with a face-centered cubic structure containing 83atomic% Ni 83 Fe 17 . In addition, as the ...

Embodiment 2

[0172] make figure 1 A bottom-type spin-valve tunnel magnetoresistive thin film having a film structure shown in (b). In this example, as the magnetization free layer 7, a Ru film (2nm) was laminated as the non-magnetic layer 9 for exchange coupling on the magnetization free layer of the CoNiFeB / NiFe film similar to the sample of the present invention in Example 1, and then a NiFe film was laminated. (3nm) as the magnetization free layer 7c, the same as the first embodiment.

[0173] The obtained magnetoresistive film had a high MR ratio and low magnetostriction as in Example 1, and also had improved heat resistance.

Embodiment 3

[0175] A bottom-type spin-valve tunnel magnetoresistive thin film using the sample of the present invention was produced in the same manner as in Example 1, except that the magnetization pinned layer 4 was made of amorphous CoFeB (3 nm).

[0176] The obtained magnetoresistive film had a high MR ratio and low magnetostriction as in Example 1, and also had improved heat resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com