Method for separating element Pd from high-level radioactive waste

A technology of high-level radioactive waste and elements, which is applied in the field of reprocessing of high-level radioactive waste in the nuclear industry, to achieve high selectivity, simple and efficient methods, and good separation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

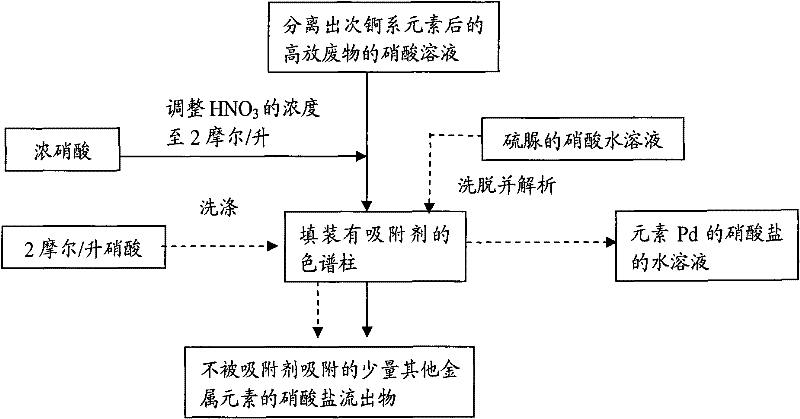

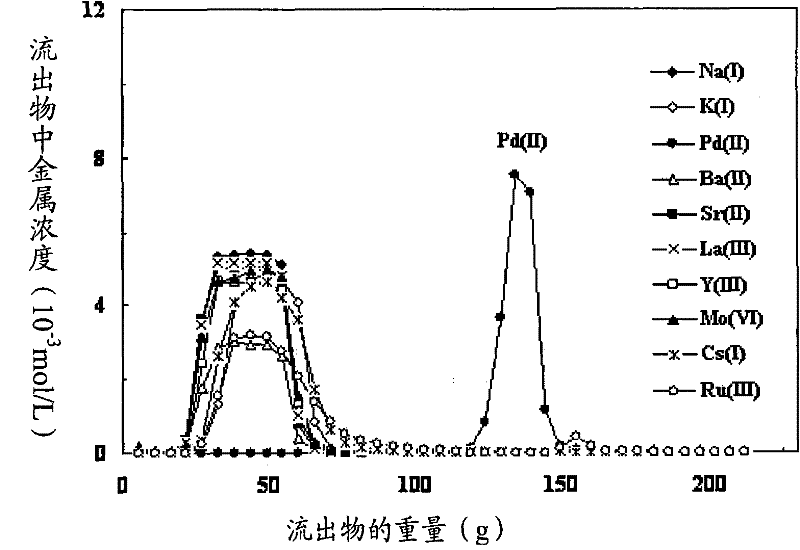

Method used

Image

Examples

Embodiment 1

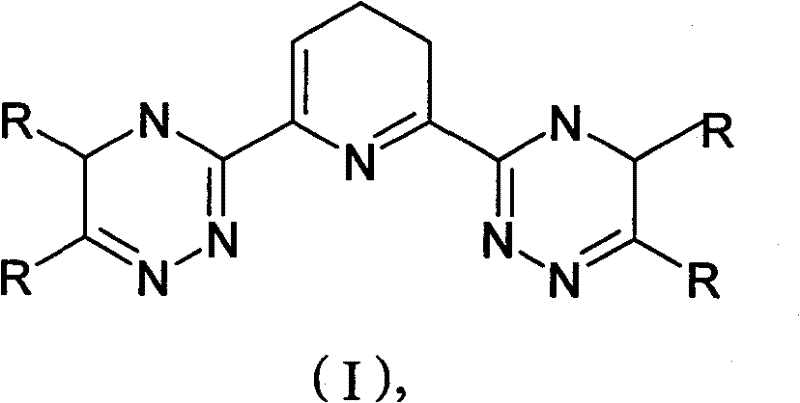

[0031] The preparation of embodiment 1 adsorbent

[0032] Dissolve 100 grams of 2,6-bis-(5,6-di-n-butyl-1,2,4-triazin-3-yl)-pyridine in 1000 mL of dichloromethane and mix well; add 300 grams of coating polymer macroporous SiO 2 (SiO 2 -P) Stir evenly to volatilize most of the dichloromethane until the material is in a nearly dry state, and then vacuum-dry the nearly dry material at 45° C. for 24 hours.

Embodiment 2

[0033] The preparation of embodiment 2 adsorbent

[0034] Dissolve 100 g of 2,6-bis-(5,6-dimethyl-1,2,4-triazin-3-yl)-pyridine in 1500 mL of dichloromethane and mix well; add 600 g of coating polymer macroporous SiO 2 (SiO 2 -P) Stir evenly to volatilize most of the dichloromethane until the material is in a nearly dry state, and then vacuum-dry the nearly dry material at 45° C. for 24 hours.

Embodiment 3

[0035] Example 3 Preparation of Adsorbent

[0036] Dissolve 100 grams of 2,6-bis-(5,6-diethyl-1,2,4-triazin-3-yl)-pyridine in 3000 mL of dichloromethane and mix well; add 1500 grams of coating polymer macroporous SiO 2 (SiO 2 -P) Stir evenly to volatilize most of the dichloromethane until the material is in a nearly dry state, and then vacuum-dry the nearly dry material at 45° C. for 24 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com