System and process for decomposing crystal seed of aluminum hydroxide

A technology of aluminum hydroxide and seed crystals, which is applied in the direction of alumina/aluminum hydroxide, can solve the problems of reducing initial investment, and achieve the effect of reducing investment and power consumption, reducing investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

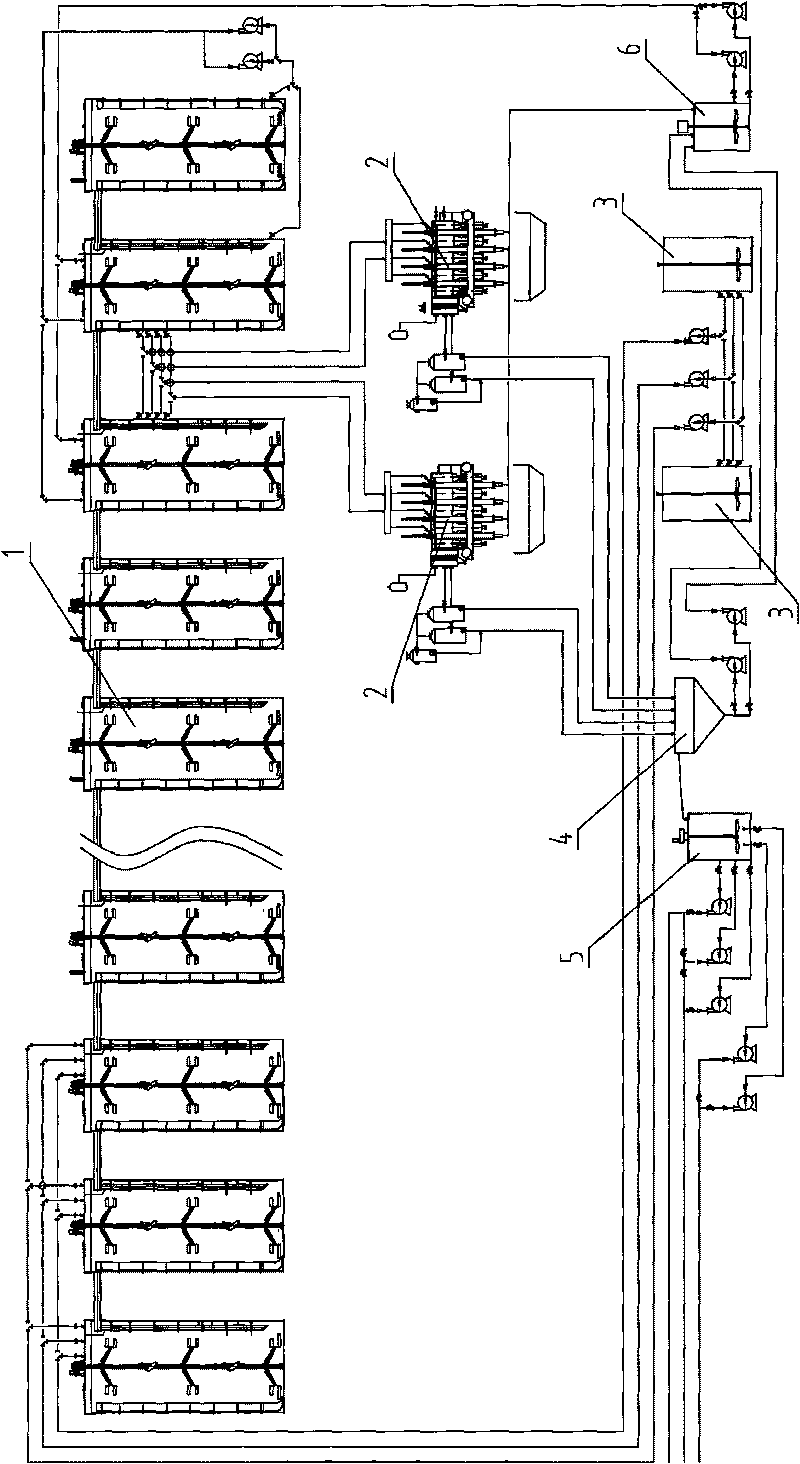

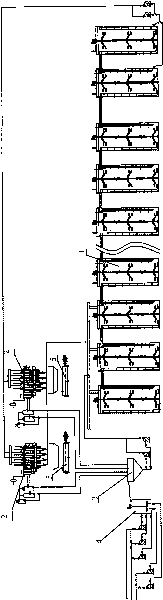

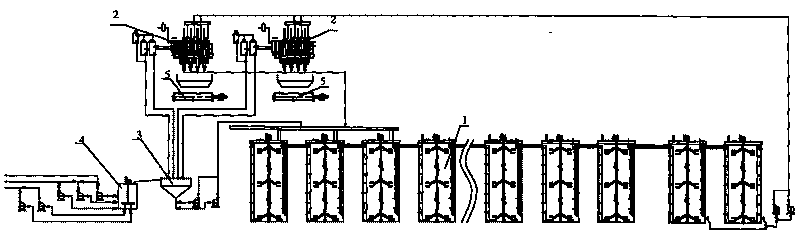

[0035] The seed crystal decomposition system of the present invention adopts the following equipment: 14 decomposition tanks, the decomposition tanks are connected to each other in sequence, and are used for the step-by-step crystallization and growth of aluminum hydroxide, and the first tank of the decomposition tank is located below the vertical plate filter;

[0036] 2 sets of vertical disc filters, installed at a height of about 51 meters, to filter the slurry from the end tank of the decomposition tank;

[0037] 2 spiralizers, set between the vertical disc filter and the first tank of the decomposition tank, mix the filter cake (ie crystal seed) of the vertical disc filter with supersaturated sodium aluminate solution to form a crystal seed slurry; The slurry flows into the first trough of the decomposition tank through the chute; then the slurry is decomposed step by step in each decomposition tank until it reaches the final trough of the decomposition tank, and the finis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com