Governing system for constant temperature and constant humidity and integral constant temperature and humidity machine

A constant temperature and humidity machine, constant temperature and humidity technology, applied in the field of compressors, devices or systems, can solve the problems of insignificant effect of condensation heat, inability to achieve interval temperature, frequent change of unit operation, etc., to improve the adjustable range, Diversified functions, increase the effect of heating mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following will be described in conjunction with the accompanying drawings and specific embodiments.

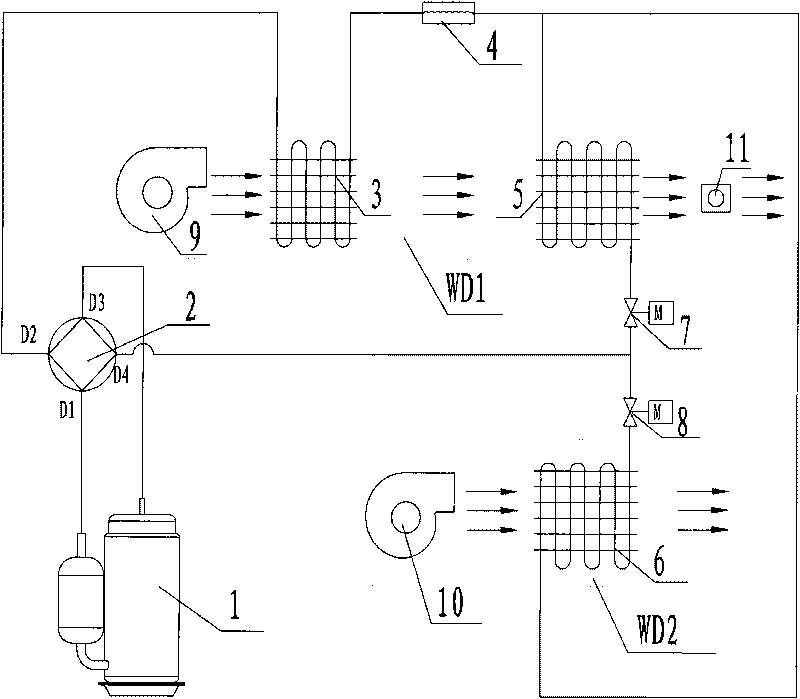

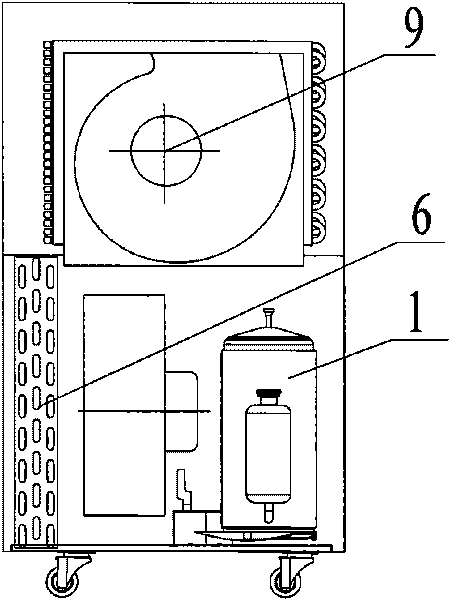

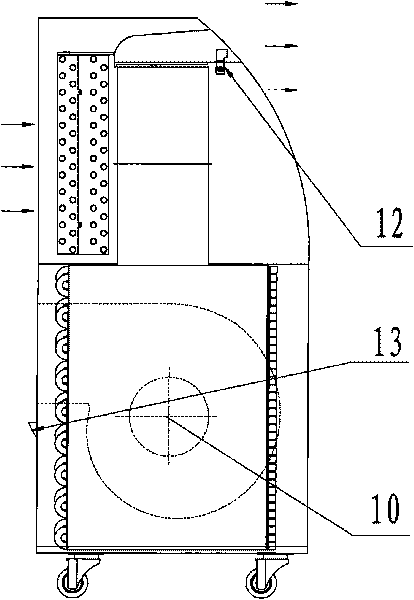

[0037] See figure 1 , which is a schematic diagram of the constant temperature and humidity regulation system of the present invention. The system is mainly composed of compressor 1, first heat exchanger 3, second heat exchanger 5, third heat exchanger 6, throttling device 4, first proportional valve 7, second proportional valve 8, four-way reversing Valve 2, humidifier 11, etc. are connected through refrigerant pipelines to form a refrigeration / heating cycle; wherein, the two branches of the first heat exchanger 3 and the second heat exchanger 5 are connected in parallel, and the second branch is installed on the two branches respectively. A proportional valve 7 and a second proportional valve 8 are used to control branch flow and on-off.

[0038] Specifically: the compressor 1, the first heat exchanger 3, the throttling device 4, and the second heat exchanger 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com