Superconductivity copper foil tape

A superconductivity, copper foil technology, used in conductive adhesives, adhesives, film/sheet adhesives, etc., can solve the problems of non-brittleness, chemical resistance and easy oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

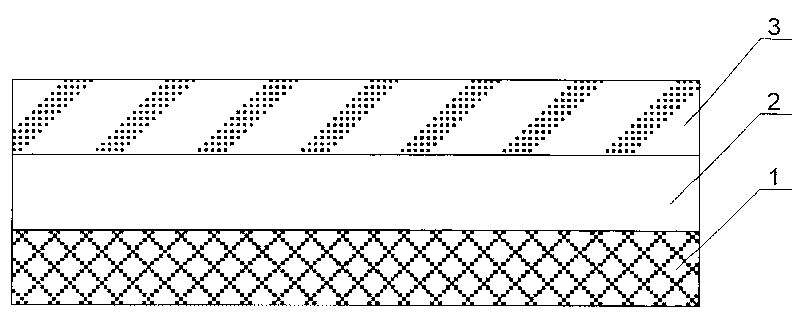

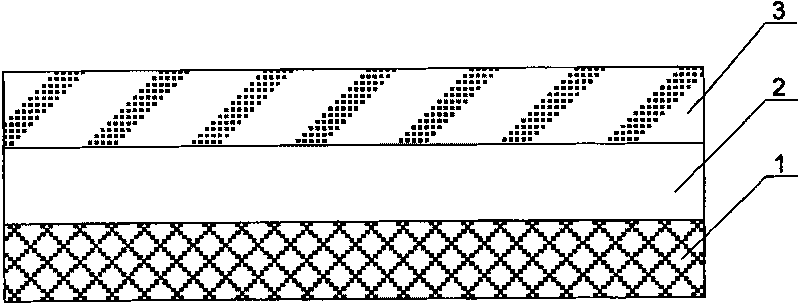

[0049] The related structure of the present invention mainly includes the following components: anti-adhesive silicone oil-coated paper 1 , conductive self-adhesive layer 2 , and tinned copper foil 3 .

[0050] In the superconductive copper foil tape of the present invention, a conductive self-adhesive layer 2 is added on the upper surface of the anti-adhesive silicone oil-coated paper 1, and a tinned copper foil 3 is added on the upper surface of the conductive self-adhesive layer 2. The thickness of the anti-sticking silicone oil-coated paper 1 is 0.15-0.39 mm, the thickness of the acrylic oily colloid layer 2 is 0.02-0.06 mm, the thickness of the tinned copper foil 3 is 0.03-0.05 mm, and the total th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com