Air inlet passage dynamic pressure acquisition and tail cone control device

A dynamic pressure and control device technology, applied in aerodynamic tests, measuring devices, instruments, etc., can solve the problems of high precision wind tunnel test and high accuracy, and achieve increased flexibility and reliability, low cost, The effect of broad adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the technical scheme of invention is described in detail:

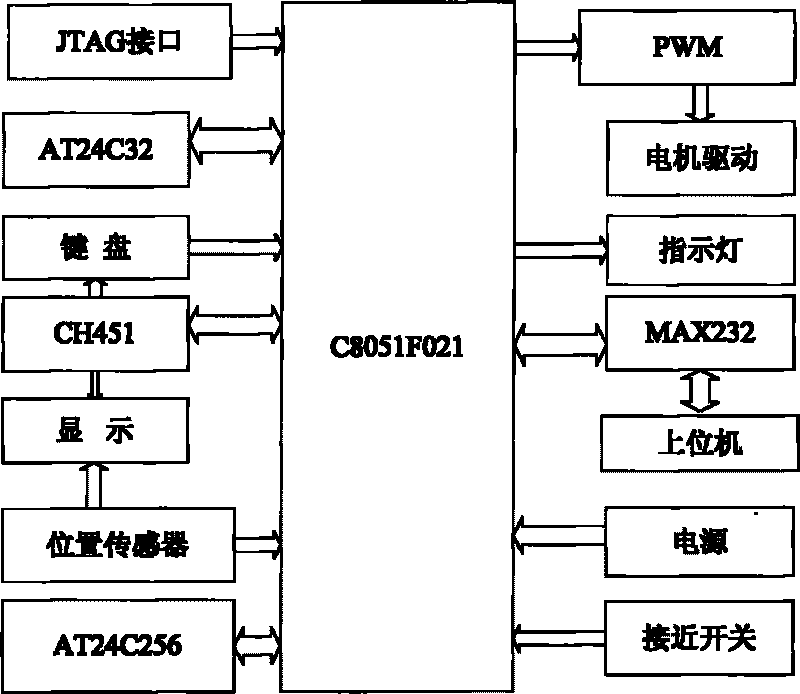

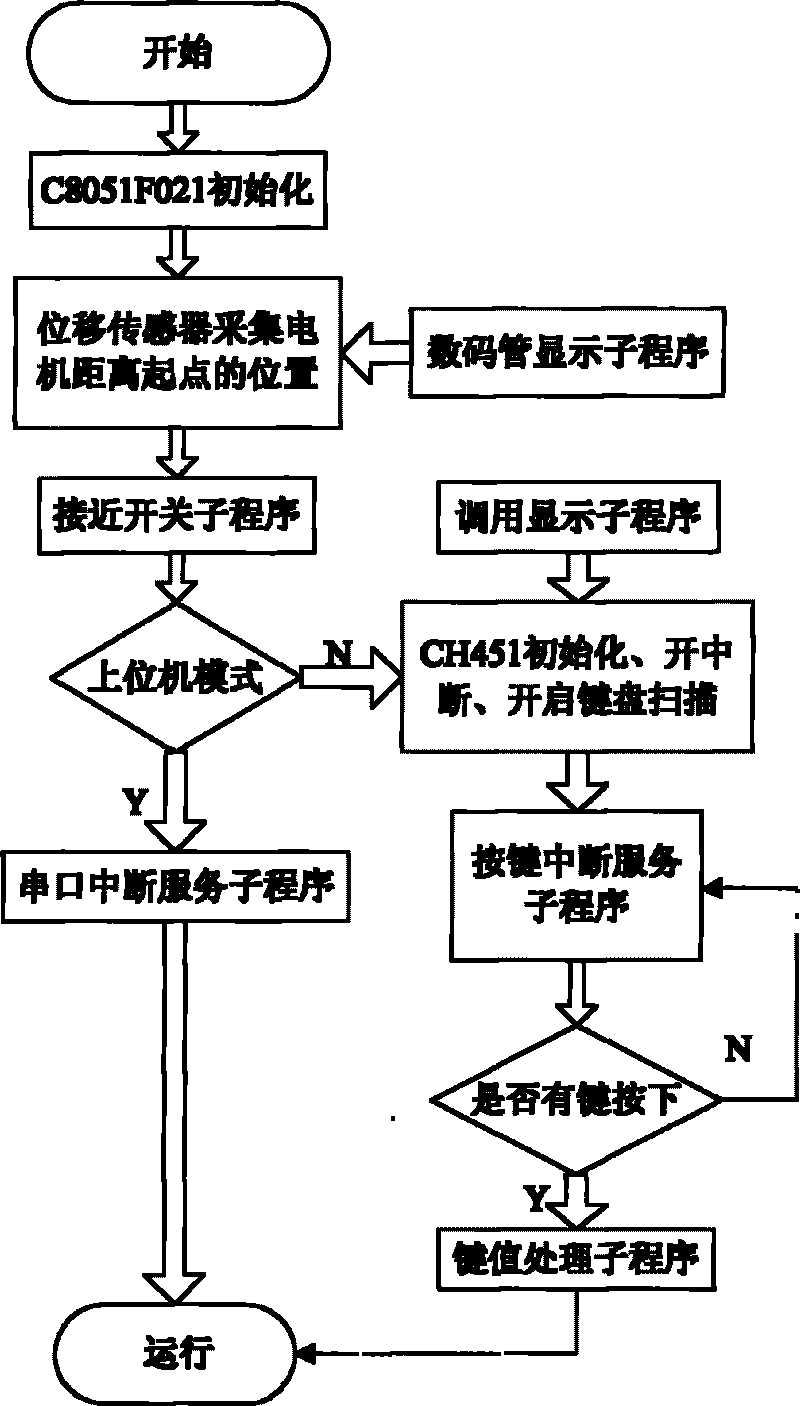

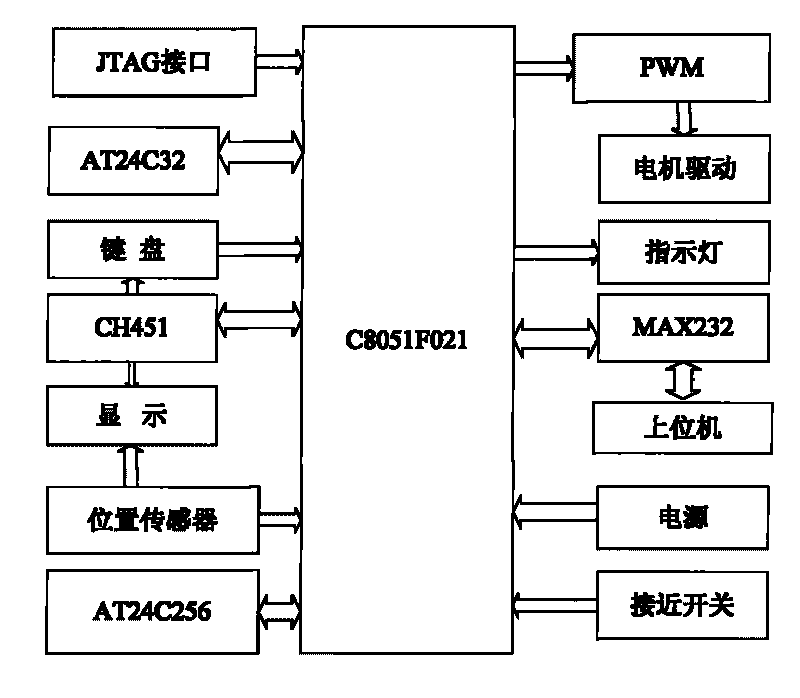

[0022] Such as figure 1 As shown, the purpose of the present invention is to design and develop an 8-channel data acquisition and tail cone control system that can accurately control the cone position and accurately measure the dynamic pressure in the blowing test of the air inlet. Accurate taper position control is achieved through the control of the stepping motor, and five operating modes of the motor, such as single-step forward, single-step backward, continuous forward, continuous backward, and online, can be set by pressing the button. At the same time, the reset function can be realized. Adjustment of motor speed and setting of operating conditions. If the input stroke is wrong, it can be reset and re-entered. After several operating conditions are input continuously in continuous mode, after the operation is completed, if you need to run the same working c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com