Polymer dispersed liquid crystal shearing effect privacy glass and preparation method and application thereof

A technology for dispersing liquid crystals and shearing effects, which is applied in optics, nonlinear optics, instruments, etc., and can solve the problems that the shearing effects of polymer dispersed liquid crystals have not been extensively researched and developed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The first step is to prepare polymer dispersed liquid crystal material

[0028] Prepare a prepolymer with 20% alkoxynonyl phenyl acrylate, 70% trimethylolpropane triacrylate, 5% chain transfer agent 2-mercaptoethanol and 5% photoinitiator 1173. The prepolymer and the nematic liquid crystal material are stirred and mixed uniformly in a mass ratio of 1:1 to prepare a polymer dispersed liquid crystal material;

[0029] The second step, coating polymer dispersed liquid crystal layer

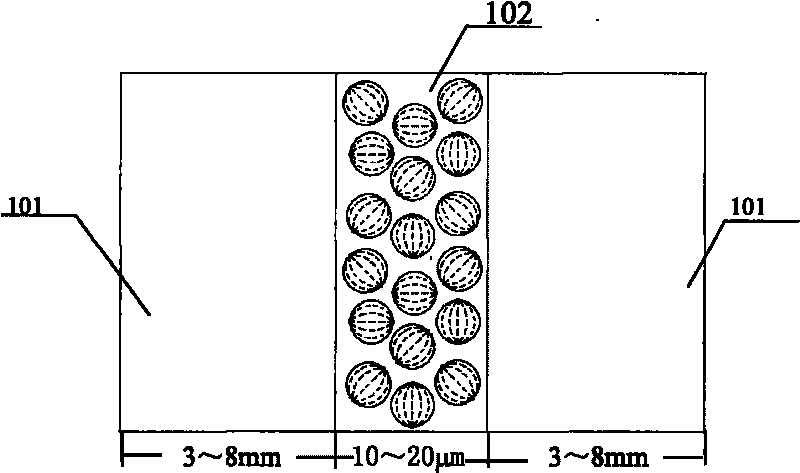

[0030] The polymer-dispersed liquid crystal material formulated in the first step is coated onto a piece of ultra-flat thick glass that is not coated with a transparent conductive layer of a transparent conductive glass for plasma display with a thickness of 3mm to form a polymer-dispersed liquid crystal layer. The thickness of the polymer-dispersed liquid crystal layer is 10 μm, and the size of the ultra-flat-thick glass used is determined by actual needs;

[0031] The third step is to prep...

Embodiment 2

[0034] The first step is to prepare polymer dispersed liquid crystal material

[0035]Prepare a prepolymer with 20% alkoxynonyl phenyl acrylate, 70% trimethylolpropane triacrylate, 5% chain transfer agent 2-mercaptoethanol and 5% photoinitiator 1173. The prepolymer and the nematic liquid crystal material are stirred and mixed uniformly in a mass ratio of 1:2 to prepare a polymer dispersed liquid crystal material;

[0036] The second step, coating polymer dispersed liquid crystal layer

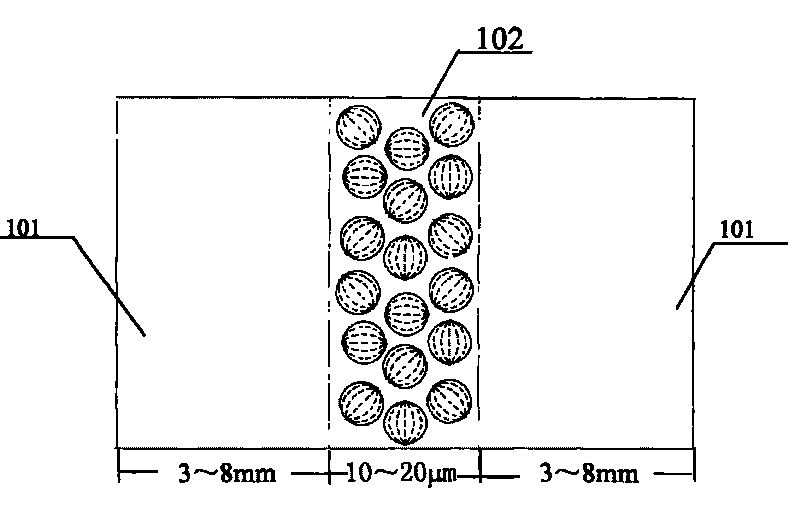

[0037] The polymer-dispersed liquid crystal material formulated in the first step is coated onto a piece of ultra-flat thick glass that is not coated with a transparent conductive layer of a transparent conductive glass for plasma display with a thickness of 5 mm to form a polymer-dispersed liquid crystal layer. The thickness of the polymer-dispersed liquid crystal layer is 15 μm, and the size of the ultra-flat-thick glass used is determined by actual needs;

[0038] The third step is to prep...

Embodiment 3

[0041] The first step is to prepare polymer dispersed liquid crystal material

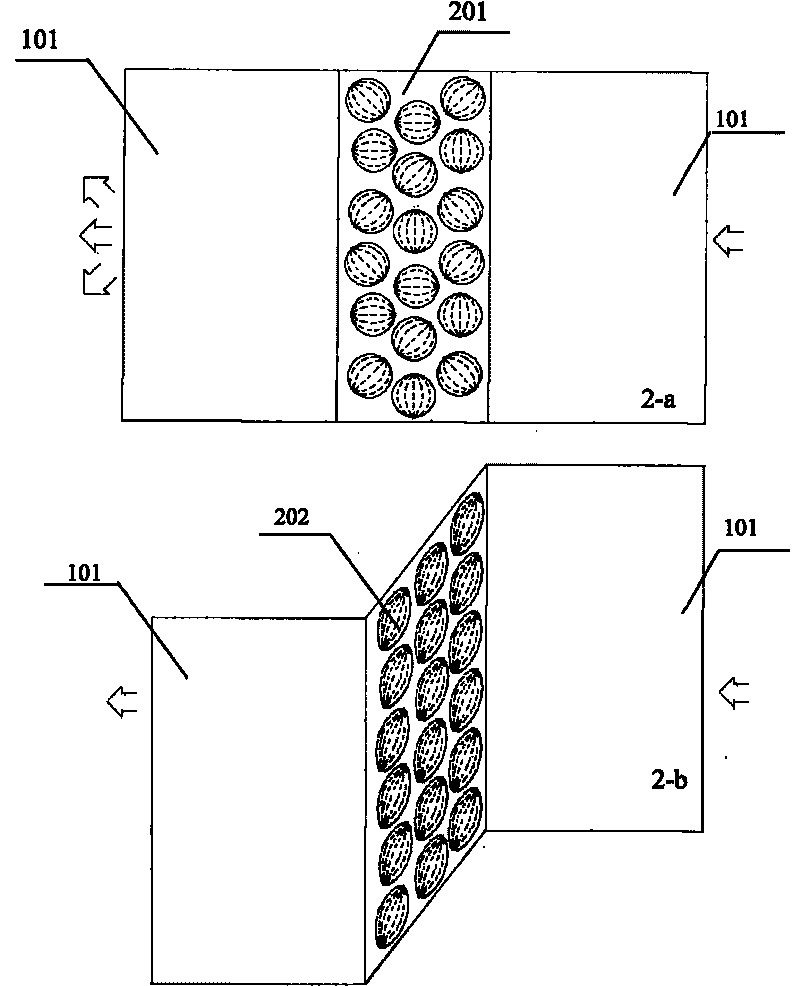

[0042] With 20% alkoxy nonyl phenyl acrylate, 70% trimethylolpropane triacrylate, 5% chain transfer agent 3-mercapto propionate isooctyl ester and 5% photoinitiator 1173 to prepare pre Polymer, the prepolymer and the nematic liquid crystal material are stirred and mixed evenly in a mass ratio of 1:3, and at the same time, soft plastic microspheres, microfilaments or fine hair debris with a diameter of 10-20 μm are added, and the dosage is The planar area of the prepared dimming glass product is calculated to be 2 , formulated as a polymer dispersed liquid crystal material;

[0043] The second step, coating polymer dispersed liquid crystal layer

[0044] Coat the polymer-dispersed liquid crystal material prepared in the first step on a piece of ultra-flat glass with a thickness of 8mm that is not coated with a transparent conductive layer of transparent conductive glass for plasma displays or liq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com