Method for making white-light LED with high color rendering index

A production method and high color rendering technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of easy color drift, insufficient color restoration, and complex driving circuits, etc., and achieve low cost, strong practicability, high light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

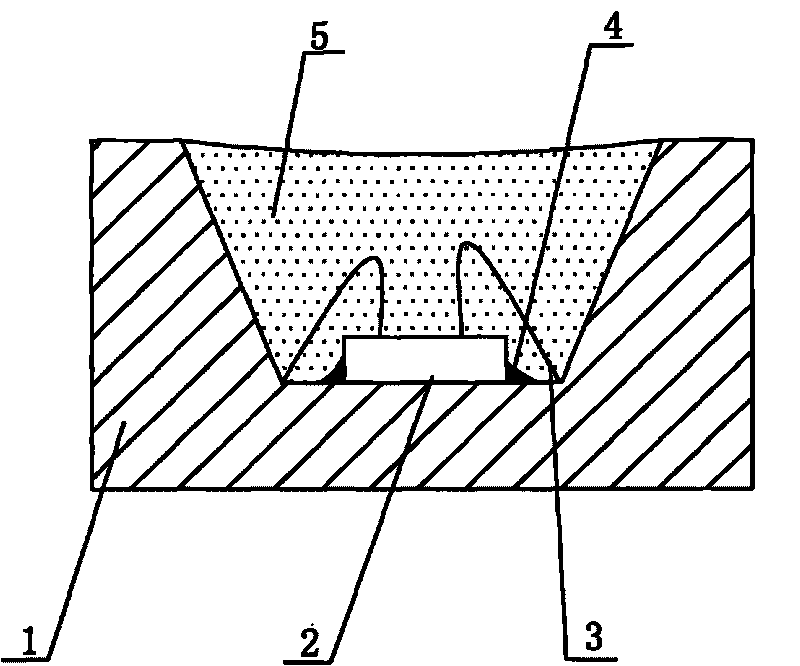

Embodiment 1

[0022] In this embodiment, the blending ratio of yellow fluorescent powder, red fluorescent powder, 500-520nm green fluorescent powder, and 520-550nm green fluorescent powder is 0.5%: 0.8%: 0.5%: 5%, and the rest is organic silica gel 5. The production method includes: The following steps: fix the blue chip 2 in the base 1 with a die-bonding adhesive 4, connect the positive and negative poles of the blue chip 2 with the lead wires of the base 1 with a gold wire 3, and solder to make it conduct. Then mix the organic silica gel 5 and the fluorescent powder according to the proportion and mix thoroughly, and apply it on the periphery of the blue chip 2, subject to covering the base 1, and finally bake and solidify it into shape. The drying temperature is 120°C-150°C, and the drying time is 1 to 2 hours, according to the different adhesives used, choose the appropriate drying temperature and drying time. The adhesive can be epoxy resin, organic silica gel or a mixture of the two. ...

Embodiment 2

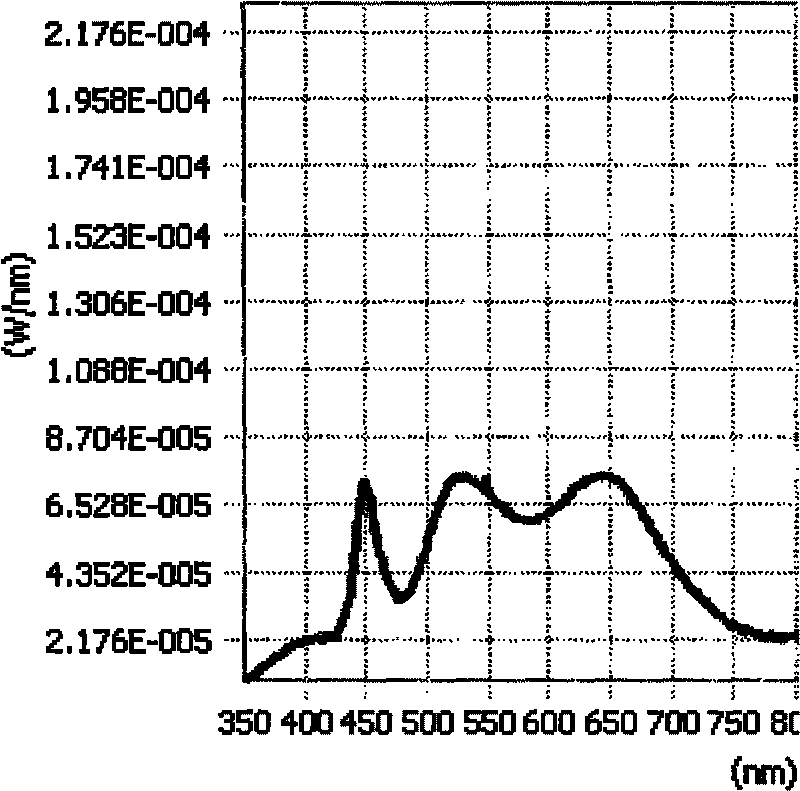

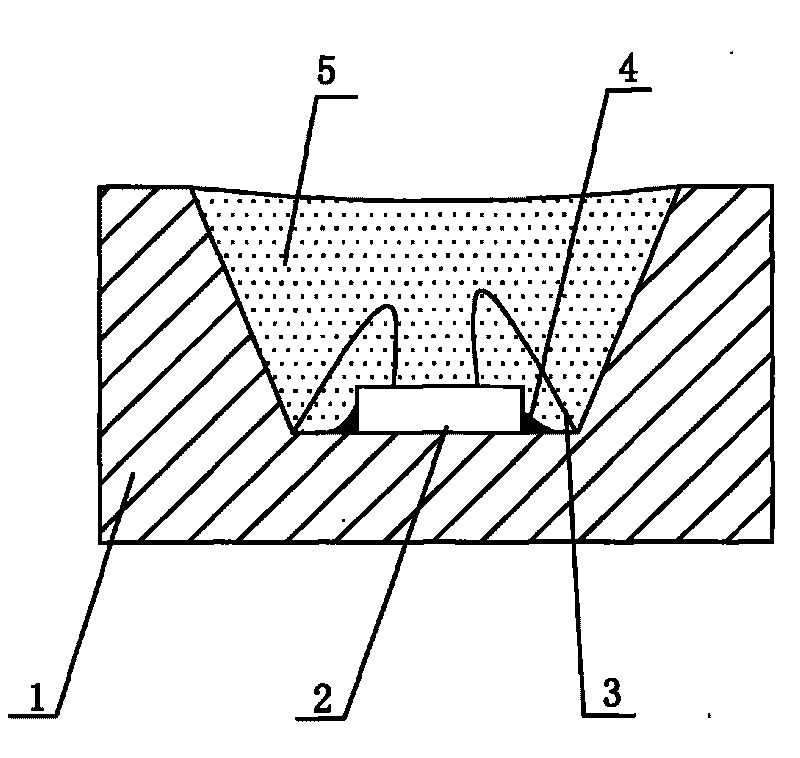

[0024] In this embodiment, the blending ratio of yellow fluorescent powder, red fluorescent powder, 500-520nm green fluorescent powder, and 520-550nm green fluorescent powder is 1%: 1.2%: 1%: 7%, and the rest is organic silica gel 5. Its production method is the same as Embodiment one is the same, adopt the spectrogram of the white light LED that the proportioning of this embodiment is made is as follows figure 2 As shown, its color temperature is around 4200K, and its color rendering index is 93.9.

Embodiment 3

[0026] In this embodiment, the blending ratio of yellow fluorescent powder, red fluorescent powder, 500-520nm green fluorescent powder, and 520-550nm green fluorescent powder is 1.5%: 1.6%: 1.5%: 8%, and the rest is organic silica gel 5. Its production method is the same as The same as in the first embodiment, the white light LED produced by adopting the ratio of this embodiment has a color temperature of about 6500K and a color rendering index Ra of 95.

[0027] The present invention can also reduce the proportion of one or several kinds of phosphors and increase the proportions of other phosphors as required, so as to produce white LEDs with different color temperatures and high color rendering index.

[0028] The basic principle of the present invention is: the blue light emitted by the blue chip excites the fluorescent powder of three colors to emit green light, yellow light and red light of two wavelengths respectively, and the green light then excites the yellow fluoresce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com