Punching structure of NC turret punch machine application switch reluctance servo motor

A technology of CNC turret punch press and switched reluctance, which is applied in punching machines, mechanical energy control, presses, etc., can solve the problems of environmental pollution, high power consumption, and high use and maintenance costs, and can save cooling systems and reduce noise. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

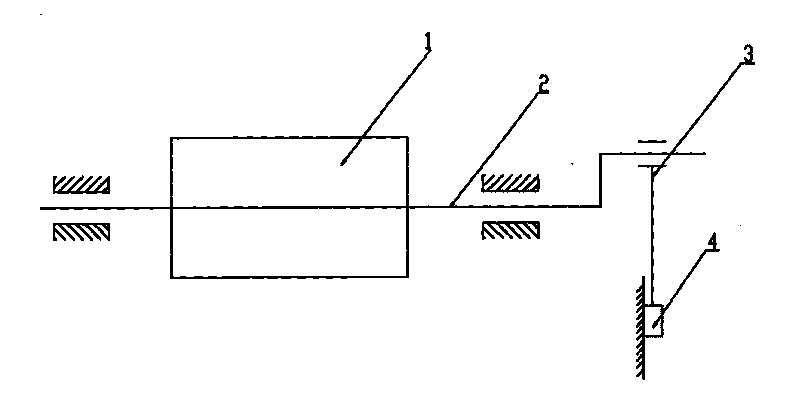

[0023] Such as figure 1 Shown: a stamping structure of a CNC turret punching machine using a switched reluctance servo motor, including a switched reluctance servo motor 1, a crankshaft 2, a connecting rod 3 and a slider 4, the switched reluctance servo motor 1 is directly installed on the crankshaft At one end of 2, the crankshaft 2 directly driven by the switched reluctance servo motor 1 is connected to the connecting rod 3, and the connecting rod 3 is connected to the slider 4 to form a planar connecting rod mechanism.

[0024] The switched reluctance servo motor 1 has a double-salient stator and rotor structure, and the rotor is made of laminated silicon steel sheets without windings and permanent magnets, allowing a relatively high temperature rise.

[0025] The rotation angle of the crankshaft 2 is controlled in a semi-closed loop by the switch reluctance servo motor 1 with its own encoder feedback. The swing angle or rotation of the crankshaft 2 is determined according ...

Embodiment 2

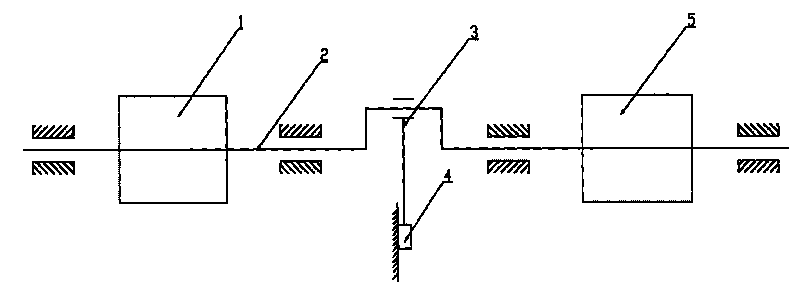

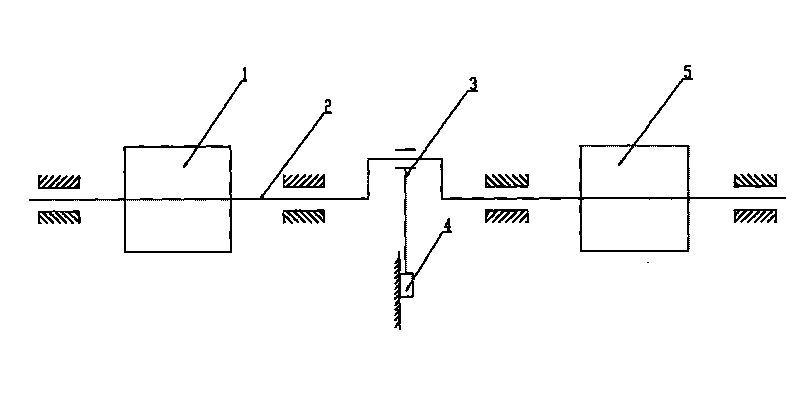

[0027] Such as figure 2 Shown: a stamping structure of a CNC turret punching machine using a switched reluctance servo motor, including a switched reluctance servo motor 1, a crankshaft 2, a connecting rod 3 and a slider 4, the switched reluctance servo motors 1 are a pair, They are directly installed at both ends of the crankshaft 2, and the crankshaft 2 is synchronously driven by the switched reluctance servo motor 1. The crankshaft 2 is connected with the connecting rod 3, and the connecting rod 3 is connected with the slider 4 to form a planar linkage mechanism.

[0028] The switched reluctance servo motor 1 has a double-salient stator and rotor structure, and the rotor is made of laminated silicon steel sheets without windings and permanent magnets, allowing a relatively high temperature rise.

[0029] The rotation angle of the crankshaft 2 is semi-closed-loop controlled by the encoder of the active motor in the pair of switched reluctance servo motors 1, and the slave m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com