Epoxy resin composite taking spherical silicon powder as filler, preparation method and application thereof

A technology of epoxy resin and spherical silicon, which is applied in the direction of electrical components, circuits, and electrical solid devices, can solve the problems of low product yield and high price, and achieve the effects of less flash, excellent flow performance, and excellent fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

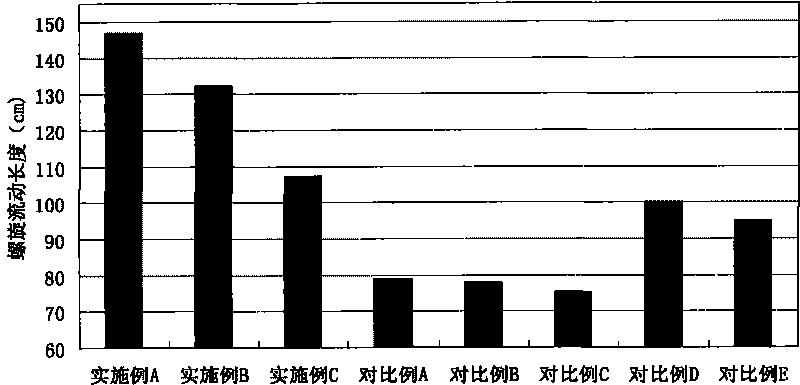

Examples

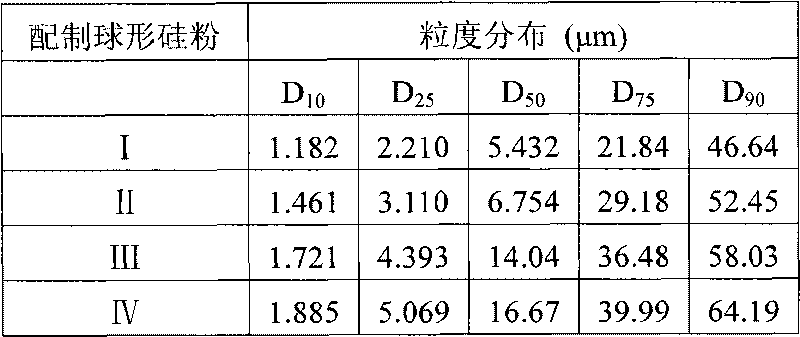

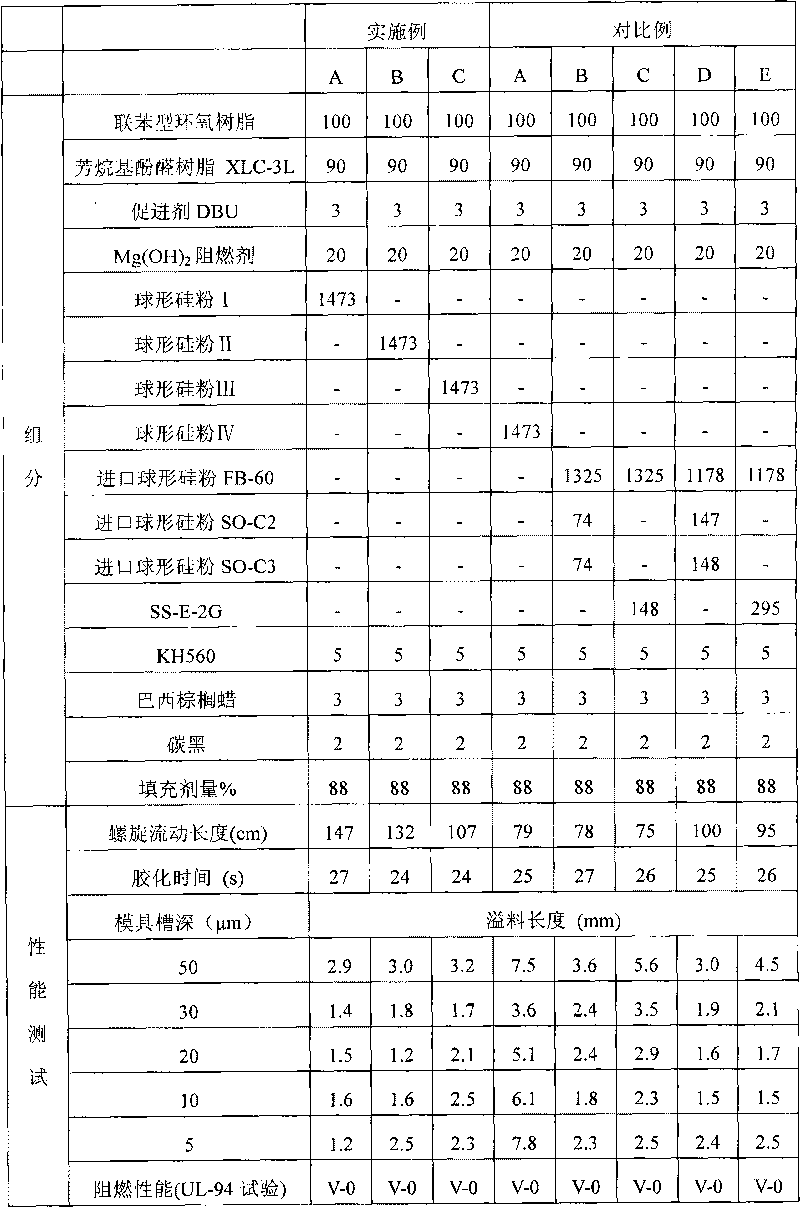

Embodiment A

[0043] Select 100 parts of biphenyl epoxy resin (DTP-101, epoxy equivalent 191, melting point 105°C), 90 parts of aralkyl phenolic resin (XLC-3L, hydroxyl equivalent 172, softening point 71.5°C), 1,8- 3 parts of diazacyclo[5,4,0]undecene-7(DBU), Mg(OH) 2 20 parts of flame retardant, 1473 parts of spherical silicon powder I, 5 parts of silane coupling agent (KH560), 3 parts of carnauba wax, 2 parts of carbon black, the above raw materials are mixed evenly in a two-roller rubber mixer, and the mixing temperature 85 ~ 90 ℃, cooling and pulverizing after kneading to make sample powder.

Embodiment B

[0045] Except for 1473 parts of spherical silicon powder II, the selected components are the same as in Example A, and the preparation method is also the same as in Example A.

Embodiment C

[0047] Except for 1473 parts of spherical silicon powder III, the selected components are the same as in Example A, and the preparation method is also the same as in Example A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com