Lead-free copper-based alloy powder material and preparation method thereof

A technology of powder material and base alloy, applied in the field of lead-free copper base alloy powder and its preparation, can solve problems such as increasing cost, and achieve the effect of saving cost, avoiding adverse consequences and improving environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

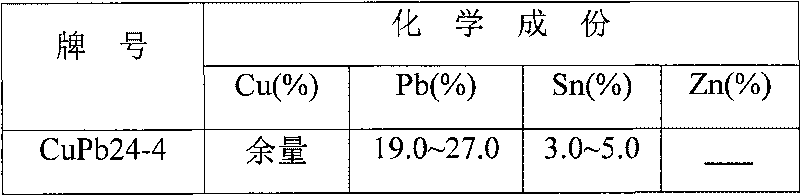

Image

Examples

Embodiment 1

[0032] 1. Product formula

[0033] 1. Raw materials

[0034] Copper: copper block or copper powder with a purity of more than 99.90% (required to contain less than 0.01% lead); tin: tin ingot or tin powder with a purity of more than 99.90% (required to contain less than 0.01% lead); zinc: more than 99.95% pure Zinc ingots (impurity content is required to be less than 0.03%).

[0035] 2. Formula (calculated according to 200kg / )

[0036] Copper weight percentage: 88%, tin weight percentage: 6%, zinc weight percentage: 6%;

[0037] Copper: 200×0.88=176(kg)

[0038] Tin: 200×0.60=12(kg)

[0039] Zinc: 200×0.60=12(kg)

[0040] Phosphor bronze: 200×0.0003÷0.14=0.43(kg)

[0041] Note: In order to increase the fluidity of the copper liquid, a certain amount of phosphorus copper is added (the content is less than 0.05%, and the content of phosphorus can be ignored).

[0042] 3. Production equipment and process

[0043] Equipment: This product is smelted by intermediate frequenc...

Embodiment 2

[0073] Lead-free copper-based alloy powder material, its formula is as follows:

[0074] Cu 87.5%, Sn 6.5%, Zn 6.0%

[0075] The performance test report of the sintered bearing material of the product described in embodiment 2

[0076] Powder material properties

[0077] The preparation method of embodiment 2 is as embodiment 1.

Embodiment 3

[0079] Lead-free copper-based alloy powder material, its formula is as follows:

[0080] Cu 88.5%, Sn 6.0%, Zn 5.5%.

[0081] The performance test report of the sintered bearing material of the product described in embodiment 3

[0082] Powder material properties

[0083] The preparation method of embodiment 3 is as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com